AGV parking system

A parking system and parking garage technology, applied in the field of logistics handling equipment, can solve problems such as troublesome operation, achieve the effect of saving lifting costs, reducing the use of equipment, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

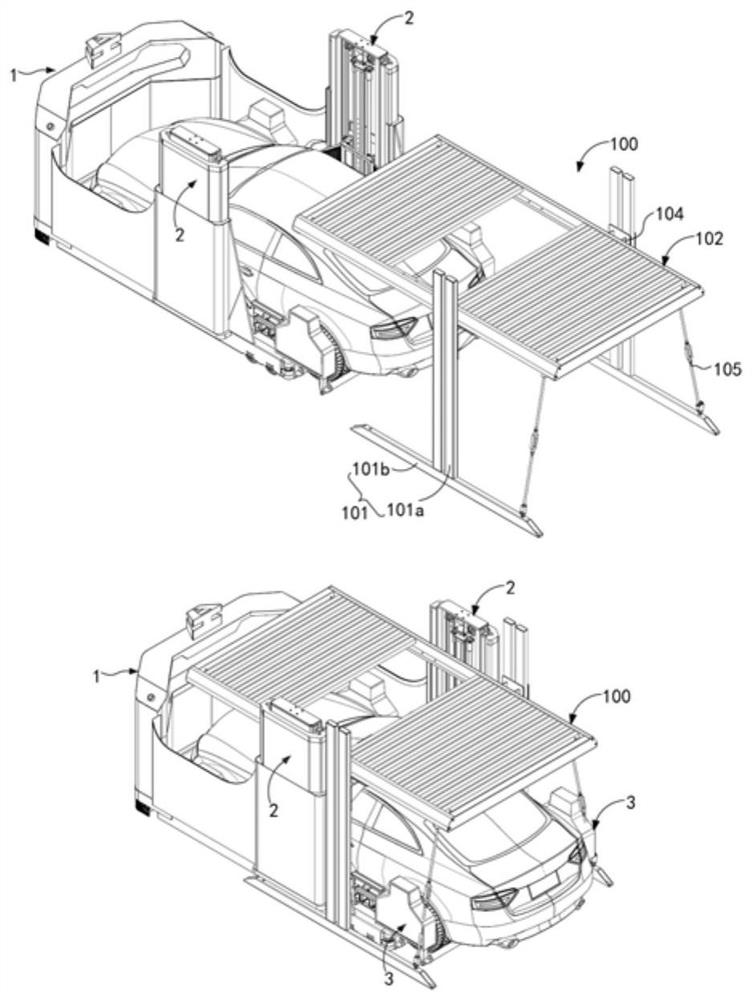

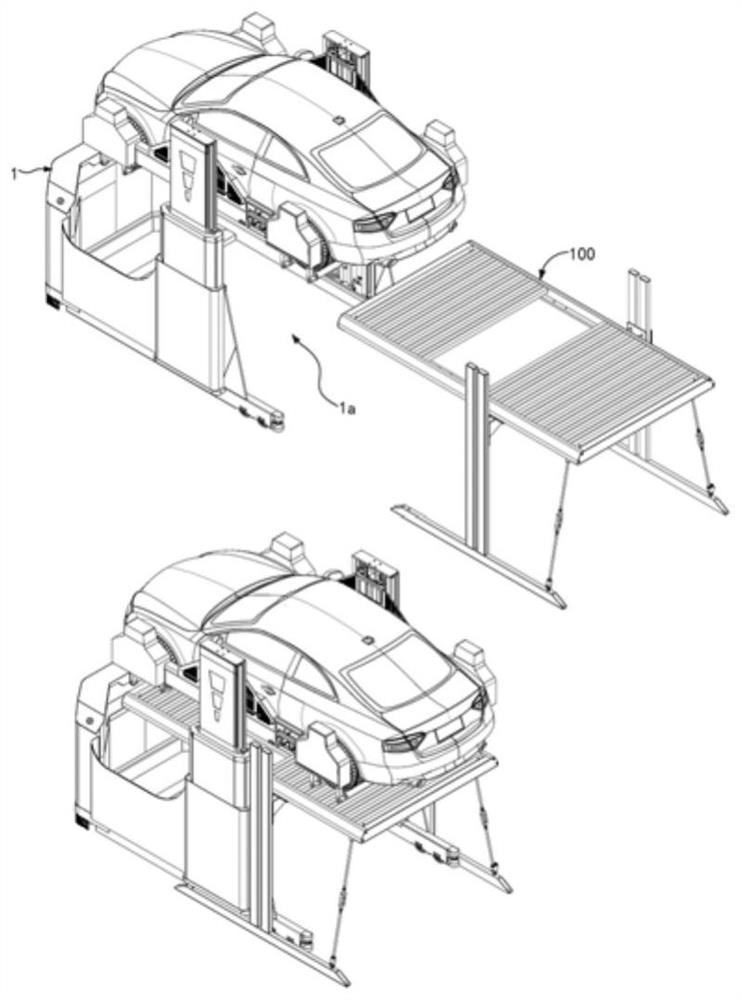

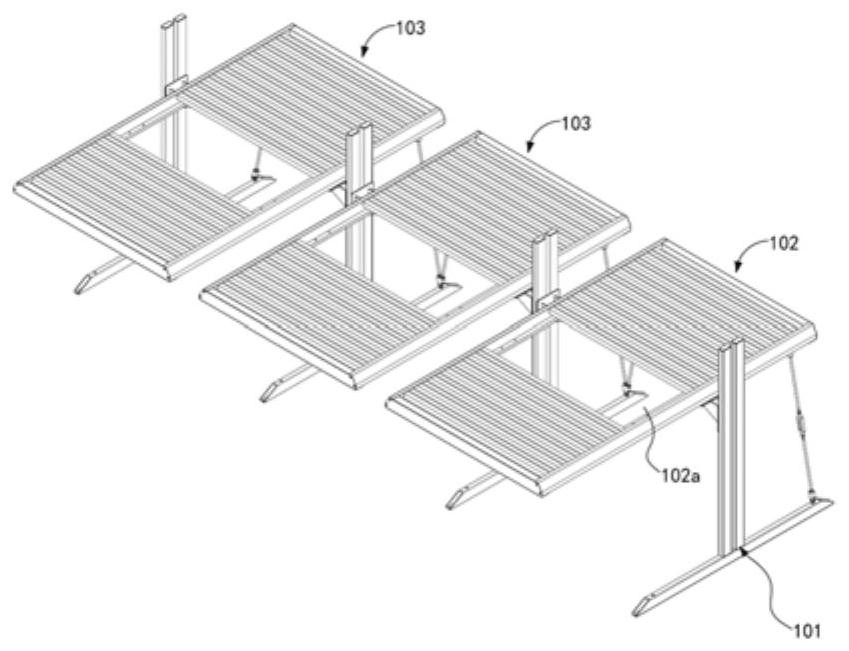

[0048] Please also refer to Figure 1 to Figure 3 , Embodiment 1 of the present invention discloses a kind of AGV parking system, comprises three-dimensional parking frame 100 and AGV car body, and this three-dimensional parking frame 100 comprises at least two layers of parking garages arranged up and down. The AGV body includes a supporting frame 1 and two lifting devices 2. The supporting frame 1 is provided with a parking space 1a for parking vehicles. The two lifting devices 2 are respectively arranged on opposite sides of the supporting frame 1. Each lifting device 2 is provided with a And clamp the clamping device 3 of the vehicle, the lifting device 2 is used to drive the clamping device 3 to move up and down in the parking space 1a, so as to drive the vehicle to go up and down to adapt to the two-story parking garage.

[0049] The parking space 1a for parking vehicles is formed in the support frame 1, and the lifting device 2 is located in the parking space 1a, so tha...

Embodiment 2

[0091] Please also refer to Figure 4 , Figure 6 to Figure 8, On the basis of the above-mentioned first embodiment, the AGV parking system of the second embodiment of the present invention further includes a connecting bracket 4, and the connecting bracket 4 is fixed on the lifting device 2. It can be seen from Embodiment 1 that there are two lifting devices 2, which are respectively arranged on the two first support rods 11,12. Each lifting device 2 is provided with two clamping devices 3 spaced apart and arranged side by side. Lifting movement. That is to say, the function of the connecting bracket 4 is not only to connect the two clamping devices 3 arranged at intervals, but also to drive the two clamping devices 3 to lift simultaneously under the drive of the lifting device 2, so as to realize the lifting of the vehicle. lift.

[0092] Further, the connection bracket 4 includes a bearing part 4a and a fixing plate 4b extending upward from the bearing part 4a, the bear...

Embodiment 3

[0104] Please also refer to Figure 9 to Figure 10 , On the basis of the first and second embodiments above, the AGV parking system of the third embodiment of the present invention, the lifting device 2 includes a first fixed gantry 2a, a first moving gantry 2b, a second moving gantry 2c, The sprocket wheel assembly and the lifting mechanism 2e, the first movable gantry 2b is slidably arranged in the first fixed gantry 2a, the second movable gantry 2c is slidably arranged in the first movable gantry 2b, and the sprocket assembly is located in the first mobile In the door frame 2b, and the sprocket assembly includes a sprocket base 2d, a sprocket 2f and a chain 2g, the sprocket base 2d is fixed on the first mobile door frame 2b, the sprocket 2f is fixed on the sprocket base 2d, and the chain 2g is wound around the sprocket 2f and the two ends of the chain 2g are respectively fixedly connected to the second mobile door frame 2c and the first fixed door frame 2a, the lifting mech...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com