Block type heading machine cutterhead driving structure

A disc-driven, block-type technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of large volume and weight, and achieve the effect of improving axial bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

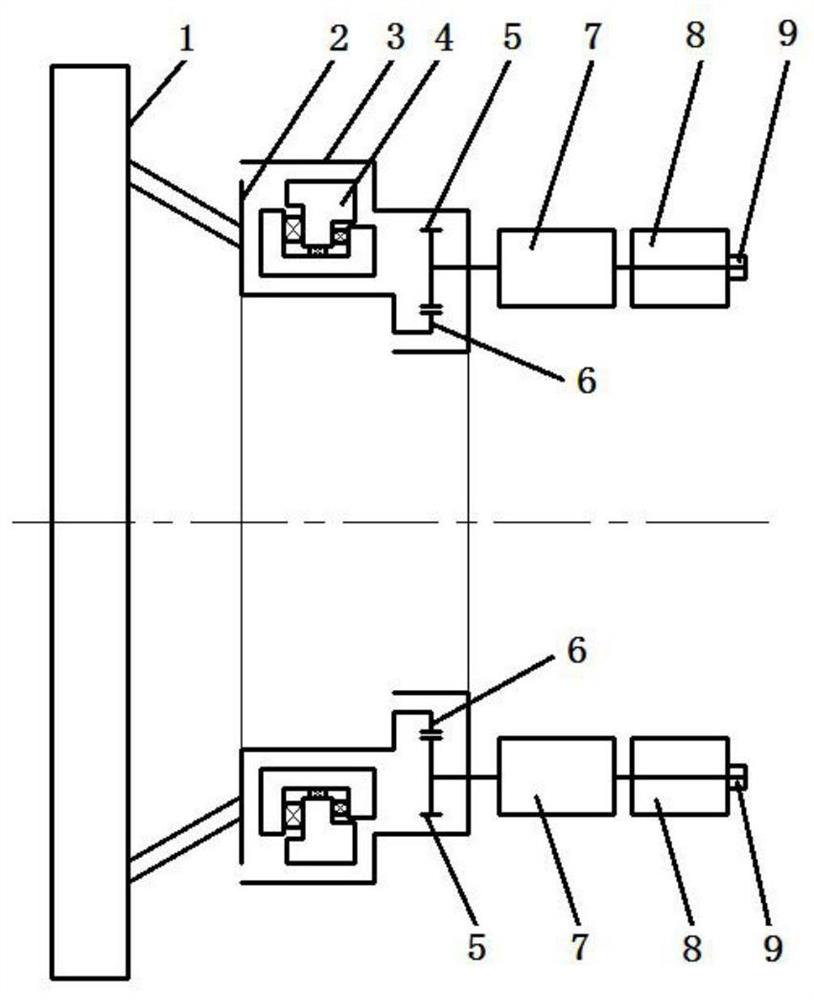

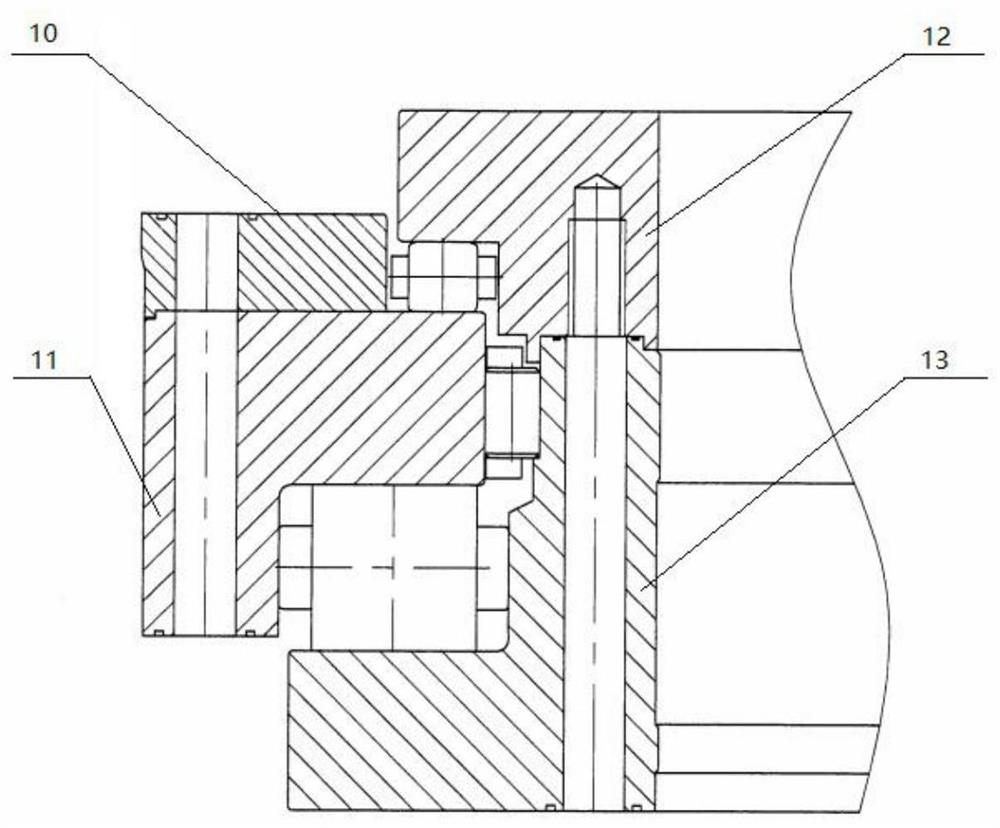

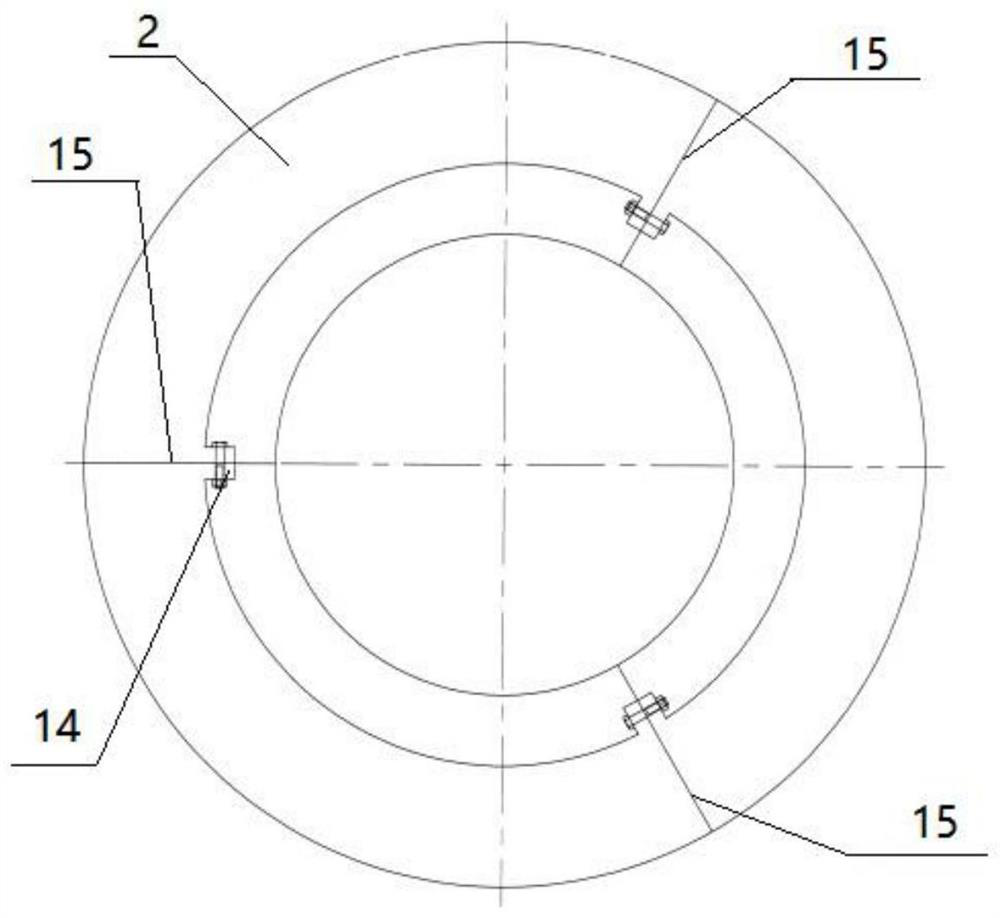

[0024] refer to Figure 1 to Figure 4 , the present invention provides a drive structure for a segmented roadheader cutter head, including a cutter head 1, a flange 2, a gearbox case 3, a main bearing 4, a gear transmission mechanism and a plurality of drive units, the main bearing and the gear transmission The mechanism is placed in the gearbox housing, and the main bearing is sleeved on the flange. One end of the flange is connected to the cutter head. The gear transmission mechanism includes a large ring gear 6 and multiple pinion gears 5. The large ring gear and multiple pinion gears are connected to each other. Gear coordination, the large ring gear is connected to the other end of the flange, and multiple pinion gears are respectively connected to mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com