Prismatic tensegrity type quasi-zero stiffness vibration isolator

A technique of tensioning the whole and quasi-zero stiffness, applied in the functional characteristics of spring/shock absorber, spring/shock absorber, coil spring, etc., to achieve the effect of high degree of generalization, simple and reliable structural design, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

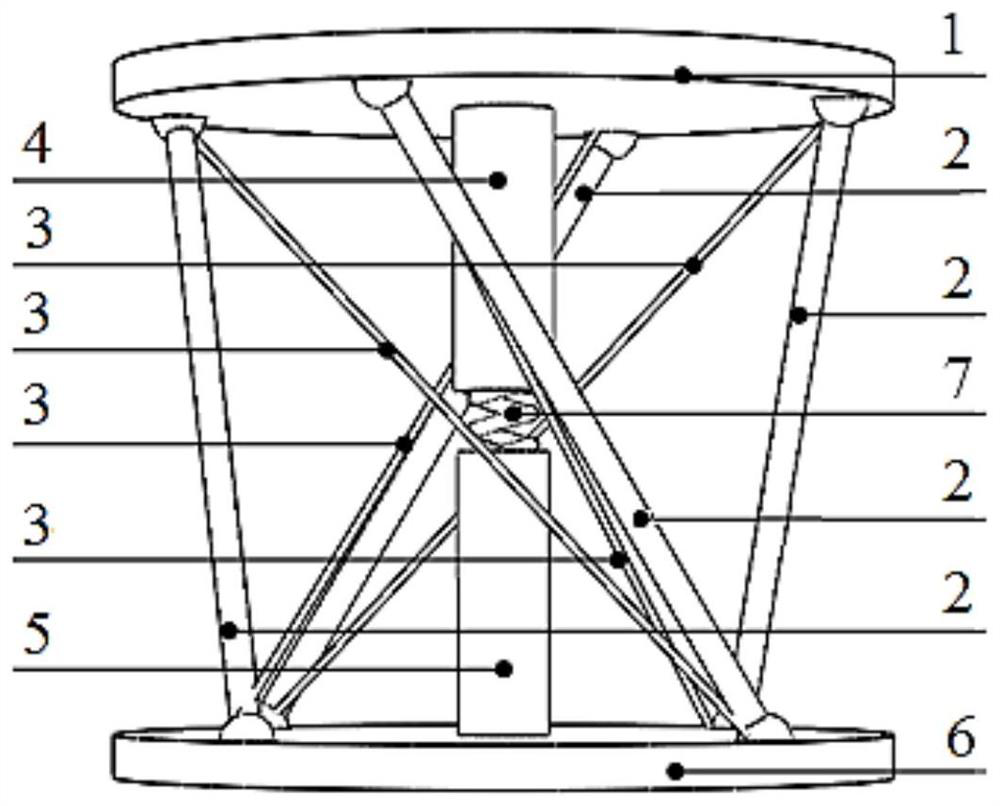

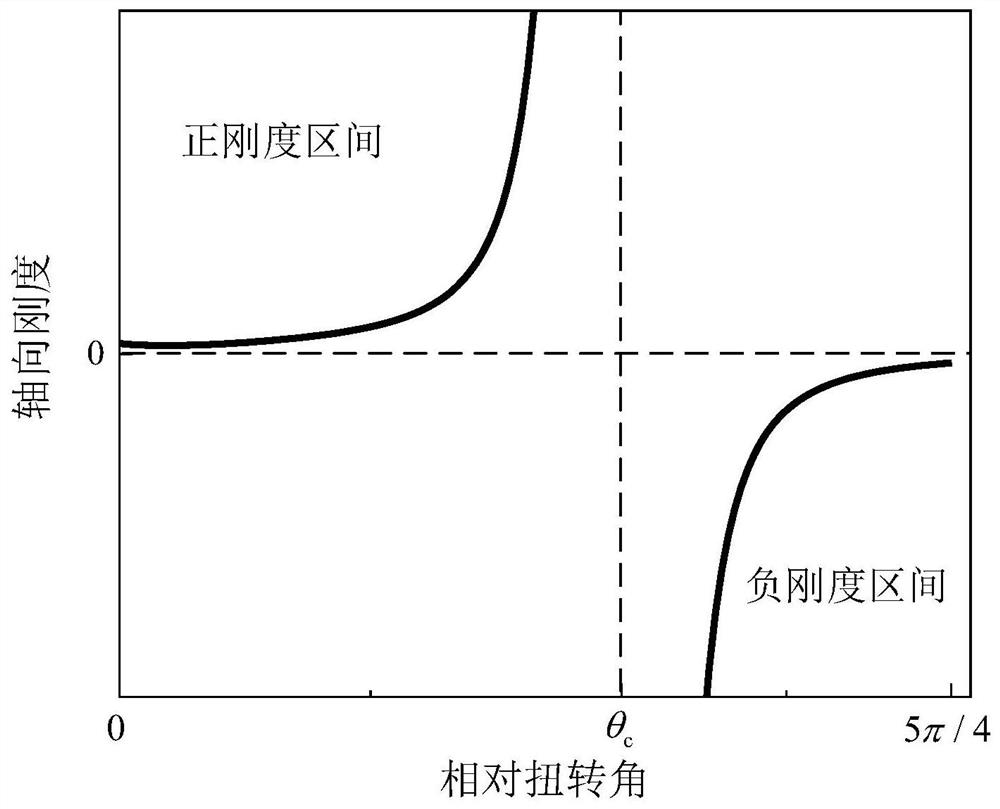

[0026] This embodiment provides a prismatic tension integral type quasi-zero stiffness vibration isolator, which not only has high static and low dynamic mechanical characteristics, but also can realize adjustable negative stiffness, simple structure, convenient installation, and effective The vibration isolation frequency range is widened, and a reliable method is provided for low-frequency axial vibration isolation control. Such as figure 1 As shown, the prismatic tensegrity integral quasi-zero stiffness vibration isolator of this embodiment includes: a coil spring 7 for providing positive stiffness and a prismatic tensegrity integral structure for providing negative stiffness, which are formed by connecting the two in parallel ;in,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com