Laser measurement adapter

A laser measurement and adapter technology, applied in the field of tooling manufacturing, can solve the problems of long manufacturing cycle and limited target base specifications, and achieve the effects of saving processing cost, shortening manufacturing cycle and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

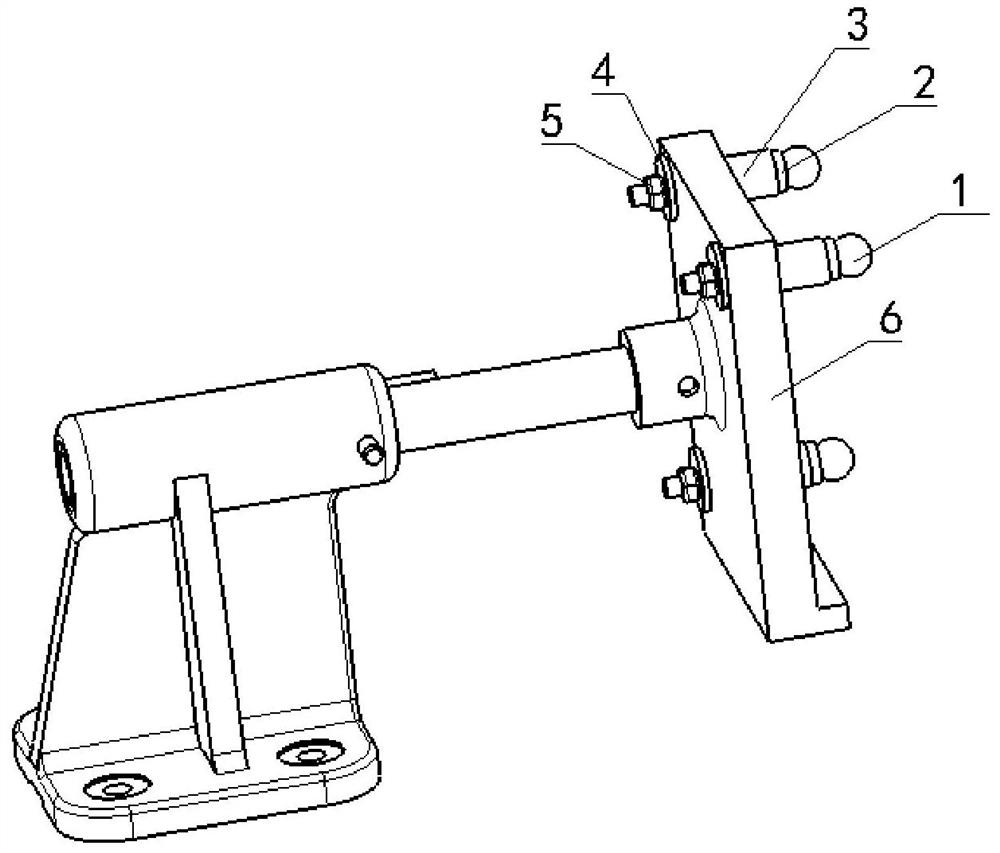

[0026] The installation device of the laser measurement adapter of the present invention is described in detail in conjunction with the accompanying drawings:

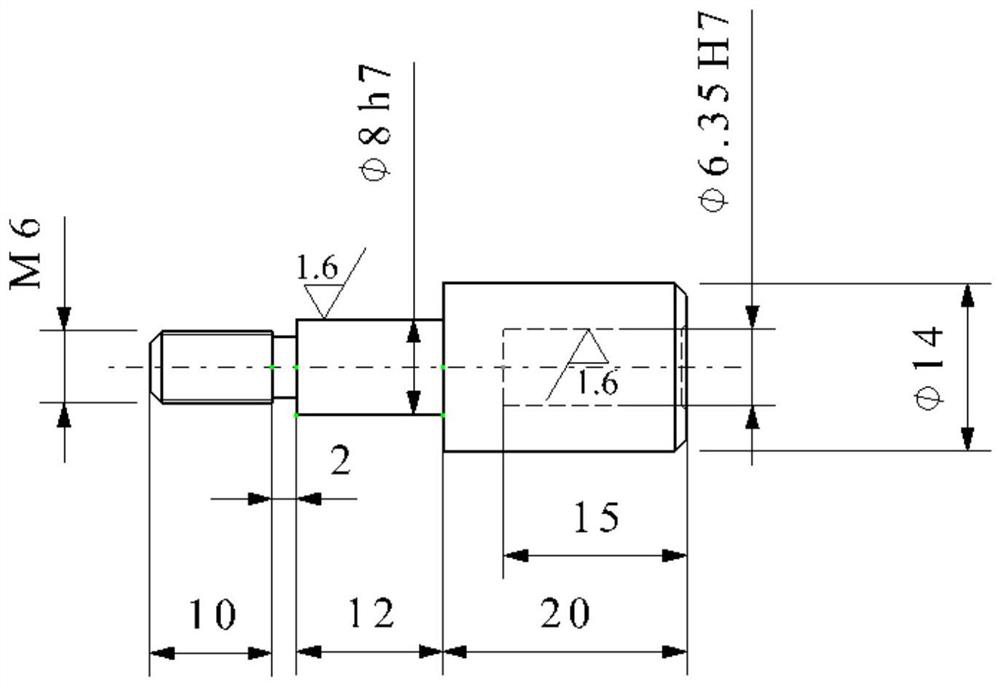

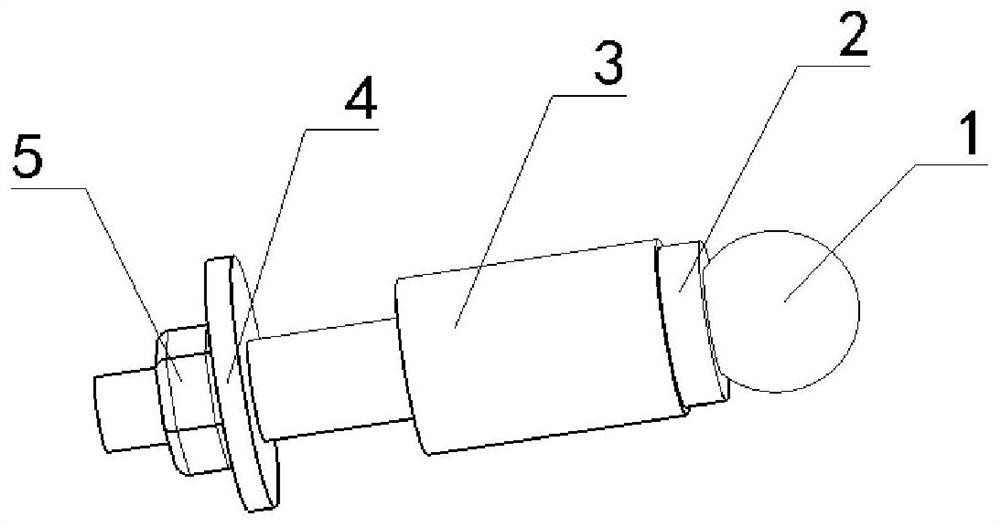

[0027] Provide a mounting device for laser measurement adapters such as figure 2 , including laser target ball (1 piece), laser target holder (1 piece), measurement adapter (1 piece), positioning washer (1 piece), nut (1 piece). , the laser target ball 1 is placed on the laser target base 2, the measurement adapter 3 includes a threaded section, a small cylinder section and a large cylinder section, the large cylinder section is provided with a matching hole for the laser target base 2, and the laser target base 2 is rotated through the measurement The matching hole of the adapter 3 is connected with the measuring adapter 3; the axis of the small cylindrical section of the measuring adapter 3 matches the hole of the workpiece to be measured, and the measuring adapter 3 includes a groove between the threaded section an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com