Cable for new energy automobile

A new energy vehicle and cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of local heat generated by friction parts, fire at gas filling stations, hidden safety hazards, etc., and achieve excellent heat conduction and heat dissipation, good mechanical strength, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

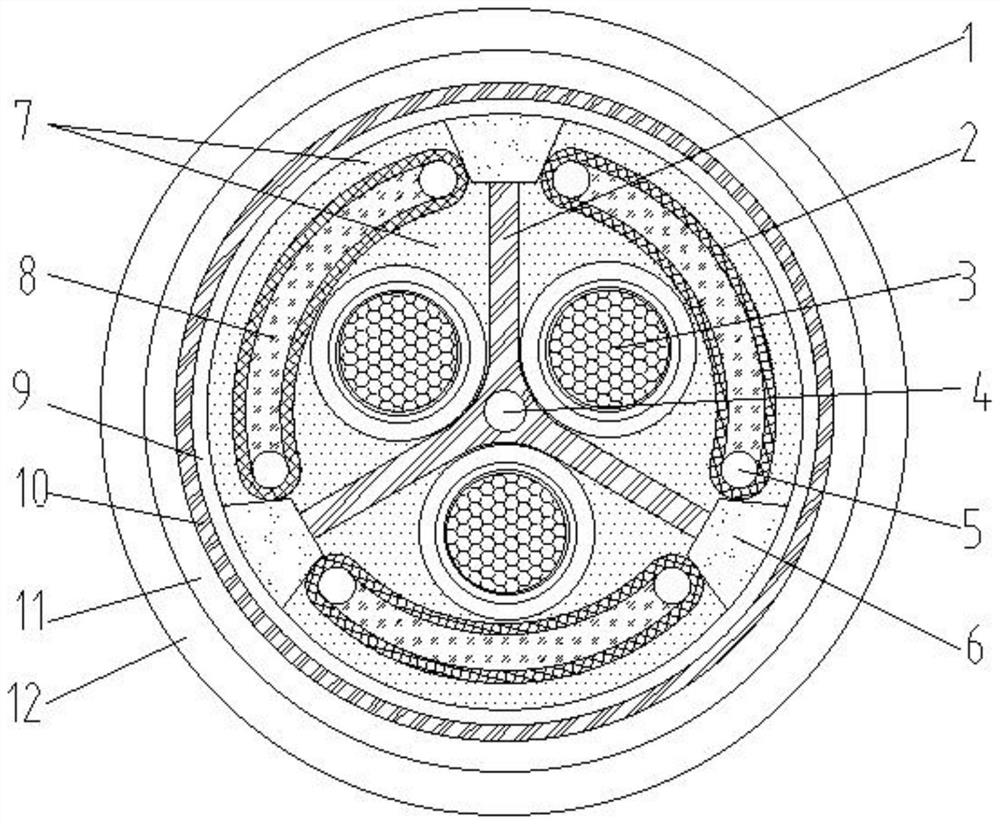

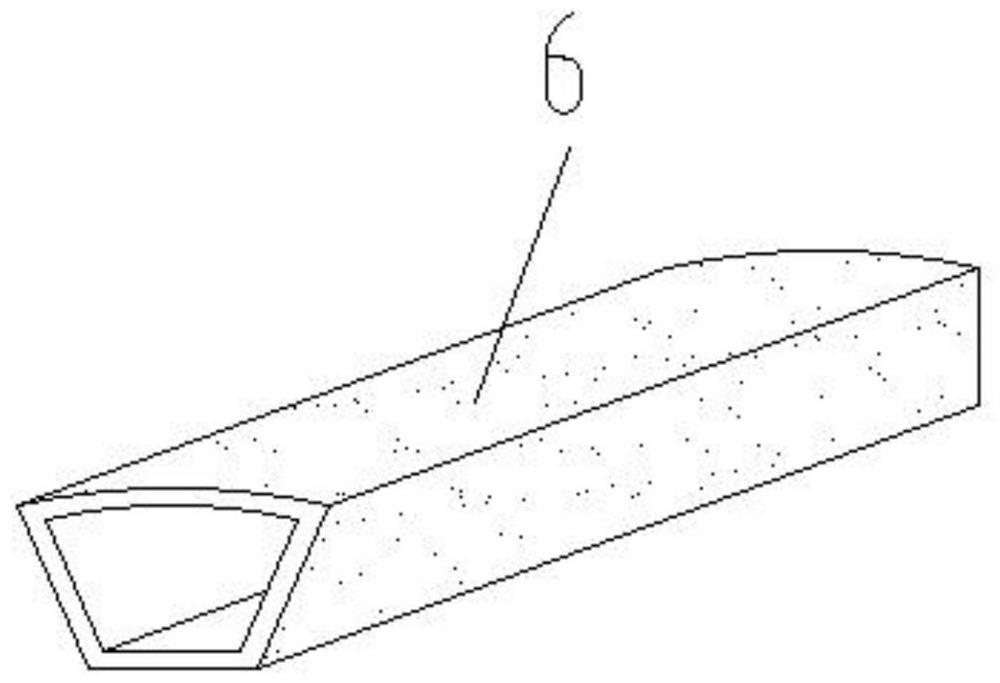

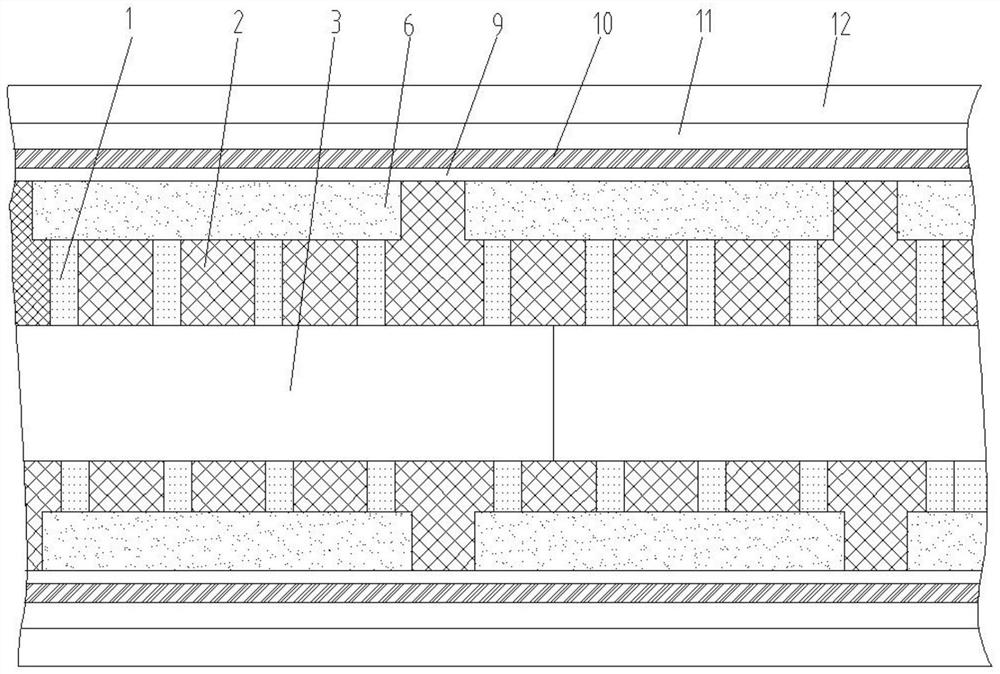

[0025] see Figure 1-3 , a cable for new energy vehicles, comprising a cable body, and the cable body includes a cable core and a cable core protective sleeve covering the surface of the cable core, and the gap in the cable core protective sleeve except the cable core is filled with fiber filler Object 7, the cable core protective cover sequentially includes a water-blocking wrapping layer 9, a shielding layer 10, an inner sheath 11 and an outer sheath 12 from the inside and outside, and the material of the water-blocking wrapping layer 9 is PE material, It has better electrical insulation and hydrophobicity, and the manufacturing cost is low. The inner sheath 11 is a flame-retardant material made of PVC modifier and PVC, so that the cable body has better flame-retardant Performance, the outer sheath 12 is made of LLDPE material, so that it has high electrical insulation, high heat resistance, impact resistance and puncture resistance, and also has excellent environmental stre...

Embodiment 2

[0035] see figure 1 , 2 And 4, the difference between embodiment two and embodiment one is:

[0036] In this embodiment, the length of the buffer profiled bracket 1 is equal to the length of the power slider 6 .

[0037] Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com