Method for manufacturing a multi-layered paperboard, multi-layered paperboard and composition for use in multi-layered paperboard manufacturing

一种多层纸板、组合物的技术,应用在造纸、造纸机、纺织品和造纸等方向,能够解决增加干燥能力、延迟、慢机器速度等问题,达到消耗低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] This example simulates the preparation of multi-layer paperboard, such as liner board, white-lined particle board or core board. Test panels were made using a Formette-Dynamic Toilet Paper Sheet Forming Machine manufactured by Techpap.

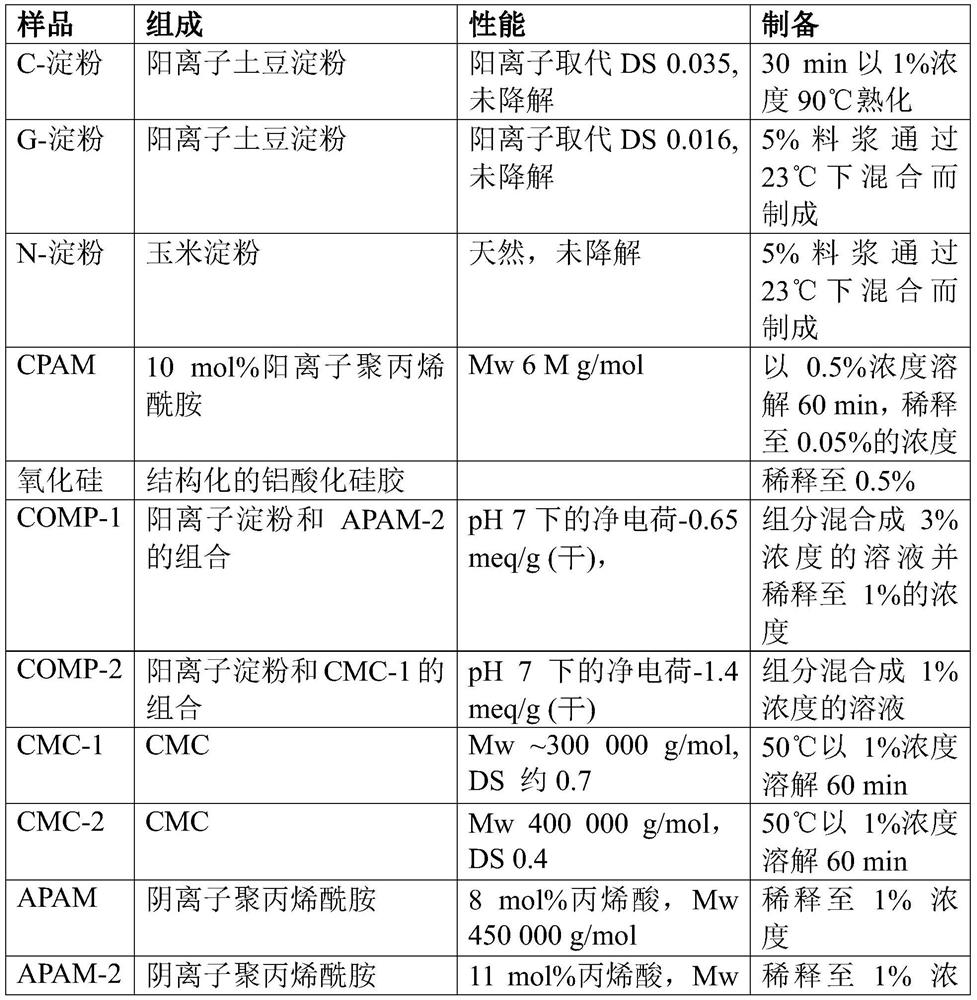

[0067] A test fiber stock was prepared to simulate recycled fiber. Central European testliner board was used as raw material. The test liner contained about 17% ash and 5% surface size starch. through CaCl 2 Ca 2+The concentration was adjusted to 520 mg / L and the conductivity was adjusted to 4 mS / cm with NaCl. Dilution water was made from tap water. The test liners were cut into 2 x 2 cm squares. Heat 2.7L of dilution water to 70°C. The test liner pieces were wetted in 2% dilution water for 10 minutes prior to disintegration. The slurry was disintegrated in a Britt jar crusher at 30,000 rpm. The slurry was diluted to 0.6% by adding dilution water. Test chemicals were prepared according to Table 1.

[0068] The test fiber stock...

Embodiment 2

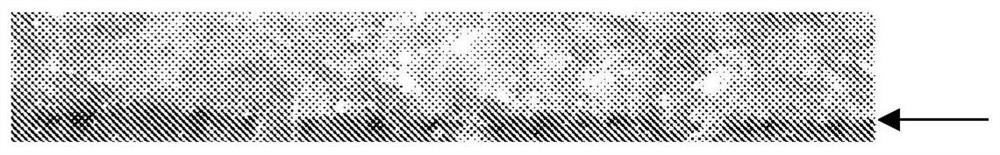

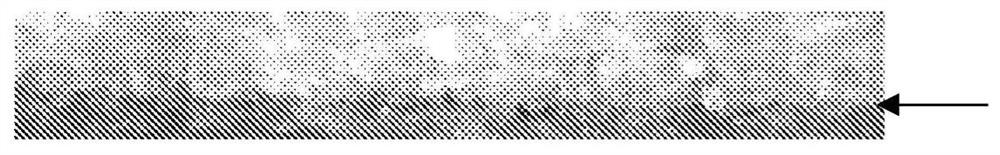

[0082] In this example, optical microscope images (1 mm wide, 0.1 mm high) were taken from transversely sliced plates stained with iodine solution. figure 1 presents a microscope image of a multilayer paperboard in which an aqueous composition according to the invention has been applied between the layers, and figure 2 A reference microscope image of a multi-ply paperboard in which an aqueous solution of granular starch has been applied between the plies is presented. These images include the middle and back laminates of the multi-ply board. The back laminate (line side) of the plyboard is the bottom side in the picture. Bond lines between the middle laminate and the back laminate are indicated by arrows in the figure. The top ply and back ply pulp was bleached kraft pulp refined to SR 25, while the middle ply pulp was bleached CTMP refined to 440 mL CSF, and the waste paper was obtained from folded cardboard veneer Disassembled above, which corresponds to the furnish fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight-average Molecular Weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| dryness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com