Camera module UV curing system based on rotary disc

A technology of camera module and turntable, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., which can solve the problems of heat dissipation, narrow space of camera and lens seat, etc., and achieve the effect of not damaging the health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

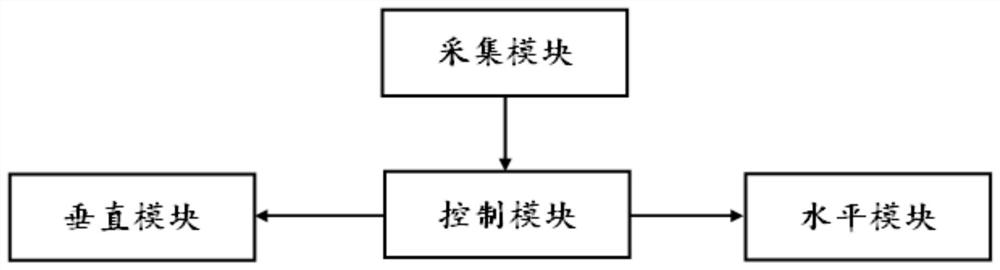

[0036] Embodiments of the camera module UV curing system based on the turntable of the present invention are basically as attached figure 1 shown, including:

[0037] Acquisition module, used to collect the real-time temperature value of UV glue, and send the real-time temperature value of UV glue;

[0038] Vertical module, for irradiating UV glue from the vertical direction by the first UV light source;

[0039] The horizontal module is used to irradiate the UV glue from the horizontal direction through the second UV light source;

[0040] The control module is used to receive the real-time temperature value of the UV glue, and according to the real-time temperature value of the UV glue, according to the preset rules, real-time control the first UV light source and the second UV light source to irradiate the UV glue to ensure the temperature of the UV glue Do not exceed the preset temperature threshold.

[0041] In this embodiment, the acquisition module is a temperature s...

Embodiment 2

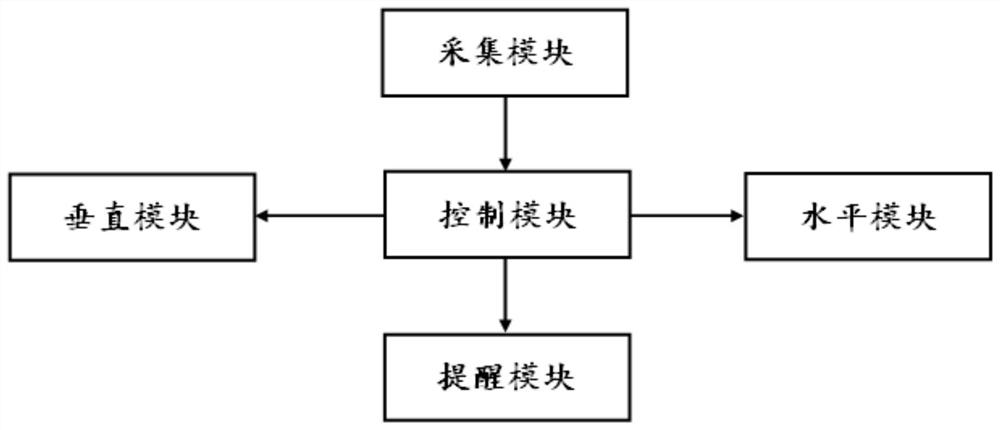

[0051] The only difference with embodiment 1 is that, as attached figure 2 As shown, a reminder module is also included, which is used to send a reminder signal to remind the staff when the intensity of the ultraviolet rays exceeds a preset intensity threshold; otherwise, not send a reminder signal to remind the staff. For example, if the intensity threshold is 80, if the detected ultraviolet intensity is 85 and exceeds the intensity threshold of 80, the buzzer will sound to remind the staff; if the detected ultraviolet intensity is 75 and does not exceed the intensity threshold of 80, the buzzer will The device does not produce sound.

[0052] In addition, considering that ultraviolet rays have a greater impact on human health, if the intensity of ultraviolet rays does not exceed the preset intensity threshold, calculate the average light intensity in the irradiation interval, and calculate the total light intensity based on the average light intensity and the irradiation in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com