Forest crusher

A technology for crushers and forest trees, which is used in wood splitting devices, wood processing appliances, chainsaws, etc., can solve problems such as damage to the lumbar spine, consumption of physical strength, and difficulty in keeping the blades in the same position, and achieves the effect of convenient placement and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

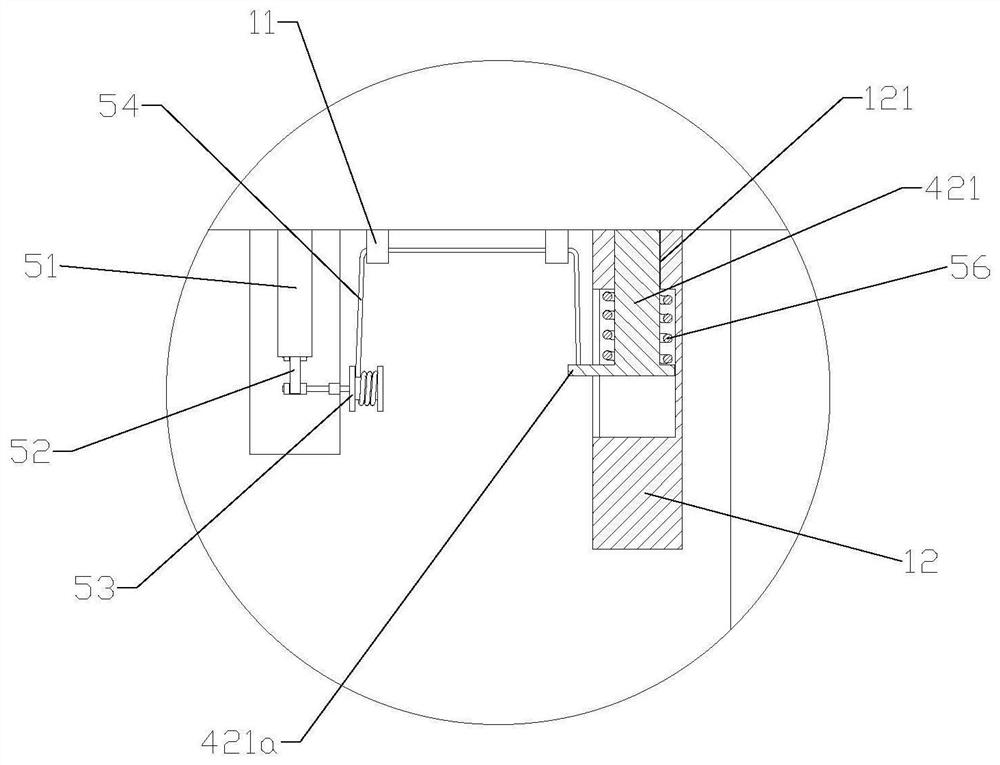

[0029] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

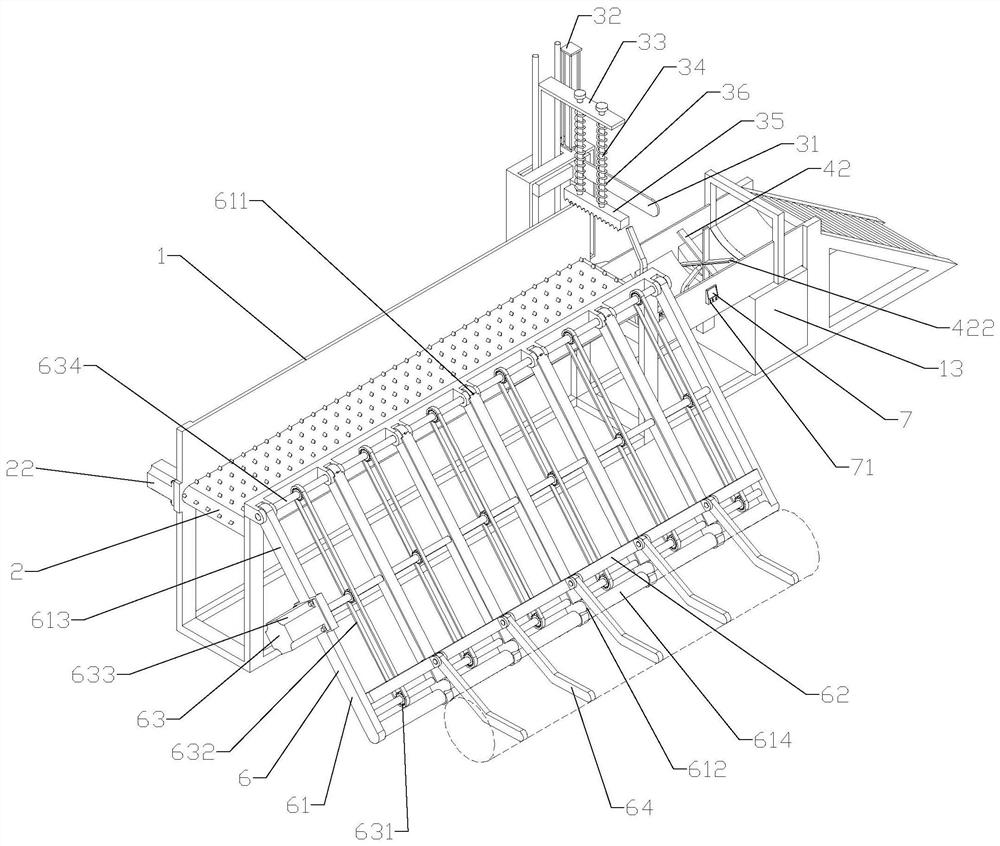

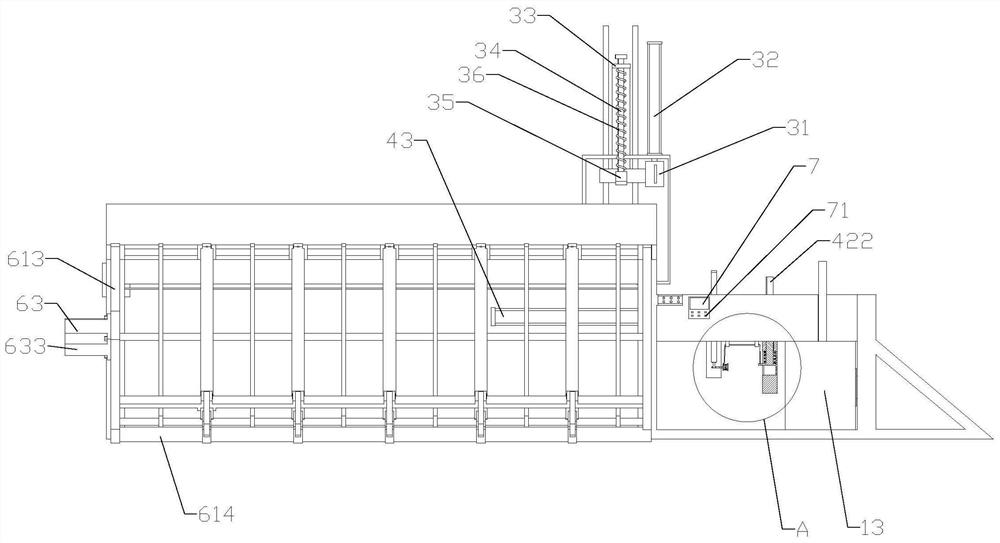

[0030] as attached figure 1 to attach Figure 10 The shown wood shredder includes a frame body 1, the frame body 1 includes a column at the bottom end and a side plate at the upper end, and the front side of the frame body 1 is horizontally provided with a bottom plate 17. The frame body 1 is provided with a conveyor belt 2 , a cutting device 3 and a crushing device 4 .

[0031] The conveyor belt 2 is horizontally arranged on the frame body 1 , and the conveyor belt 2 adopts the prior art, and the driving device 22 of the conveyor belt 2 is arranged on the side wall of the frame body 1 . In order to prevent the conveyor belt 2 from slipping during the process of conveying forest trees, friction strips 21 are densely covered on the surface of the conveyor belt 2, and the friction strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com