Shifting injection mold and use method thereof

A mold and moving mold technology, which is applied in the field of displacement and injection molds, can solve the problems of plastic body falling off the side wall, the cost of shoe soles, and low production efficiency, and achieve the goals of reducing labor costs, excellent social value, and improving quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

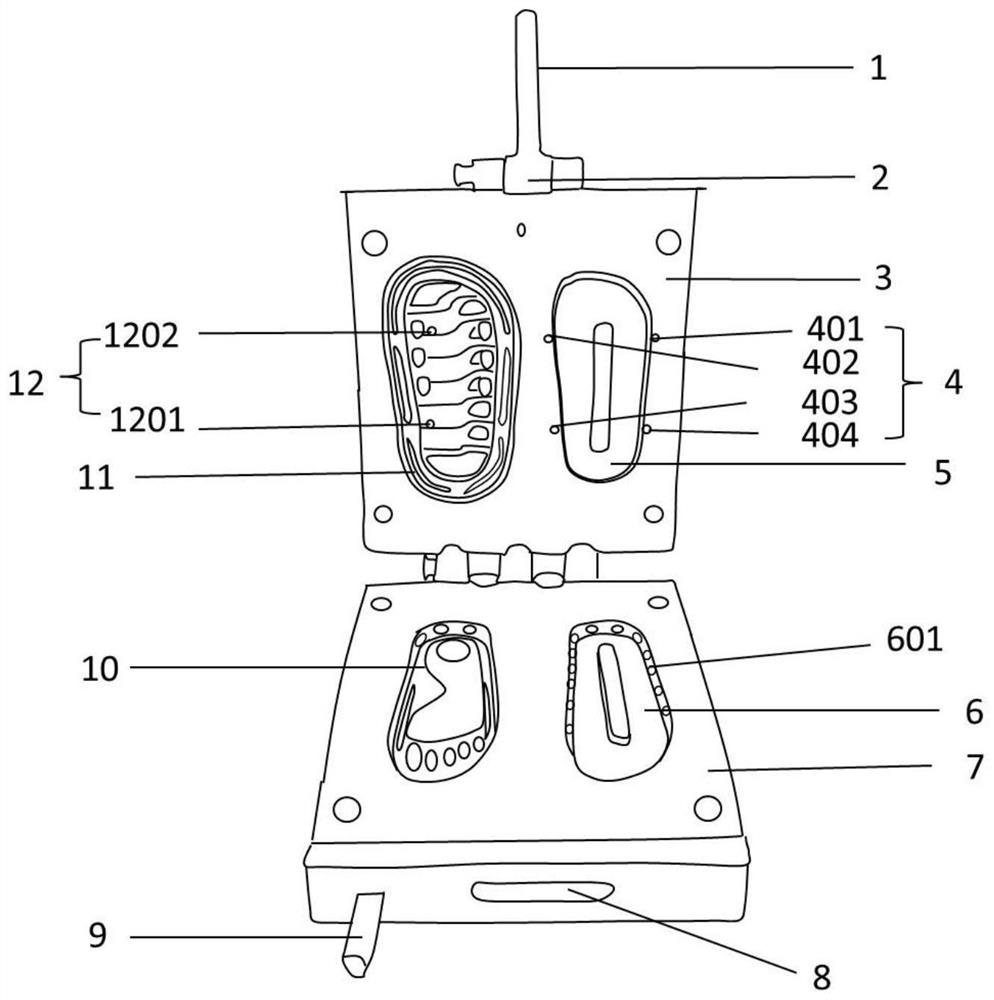

[0058] A displacement containing injection mold is provided, including: a first handle 1, a movable mold 3, and a fixed mold 7; the first handle 1 is arranged at the front end of the movable mold 3; a limiting groove 2 is also provided on the first handle 1; the The movable mold 3 and the fixed mold 7 are flexibly connected by a shaft; the inner surface of the movable mold 3 is provided with a side wall punch 5 and a shoe sole punch 11; the surrounding of the side wall punch 5 is provided with a side wall feed port 4 ; The inside of the sole punch 11 is provided with a sole feed port 12 ; the inner surface of the fixed mold 7 is provided with a side wall die 6 and a sole die 10 .

[0059] The side wall feed port 4 includes a first side wall feed port 401, a second side wall feed port 402, a third side wall feed port 403, and a fourth side wall feed port 404;

[0060] The sole feeding port 12 includes a first shoe sole feeding port 1201 and a second shoe sole feeding port 1202 ...

Embodiment 2

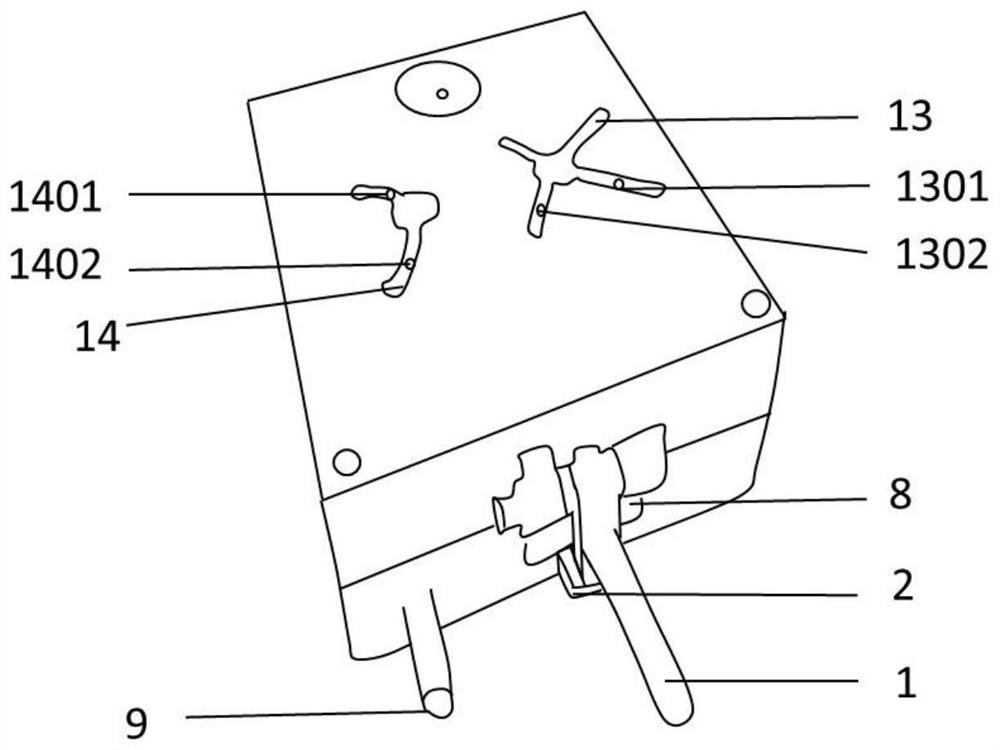

[0073] A displacement containing injection mold is provided, including: a first handle 1, a movable mold 3, and a fixed mold 7; the first handle 1 is arranged at the front end of the movable mold 3; a limiting groove 2 is also provided on the first handle 1; the The movable mold 3 and the fixed mold 7 are flexibly connected by a shaft; the inner surface of the movable mold 3 is provided with a side wall punch 5 and a shoe sole punch 11; the surrounding of the side wall punch 5 is provided with a side wall feed port 4 ; The inside of the sole punch 11 is provided with a sole feed port 12 ; the inner surface of the fixed mold 7 is provided with a side wall die 6 and a sole die 10 .

[0074] The side wall feed port 4 includes a first side wall feed port 401, a second side wall feed port 402, a third side wall feed port 403, and a fourth side wall feed port 404;

[0075] The sole feeding port 12 includes a first shoe sole feeding port 1201 and a second shoe sole feeding port 1202 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com