Temperature sensor transferring carrying system and using method thereof

A technology of temperature sensor and handling system, applied in transportation and packaging, conveyor objects, conveyors, etc., can solve problems such as low handling efficiency and accuracy impact, and achieve the effect of easy processing, improved consistency, and simple and efficient structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

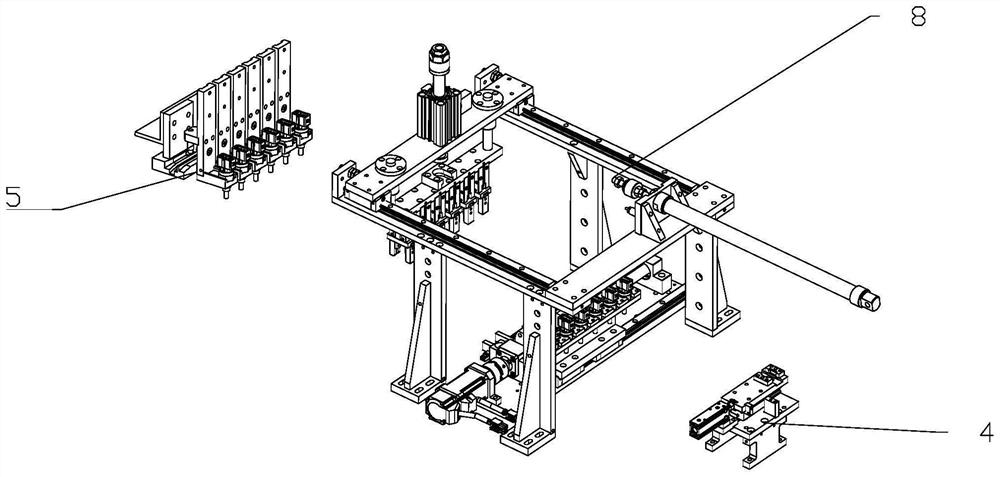

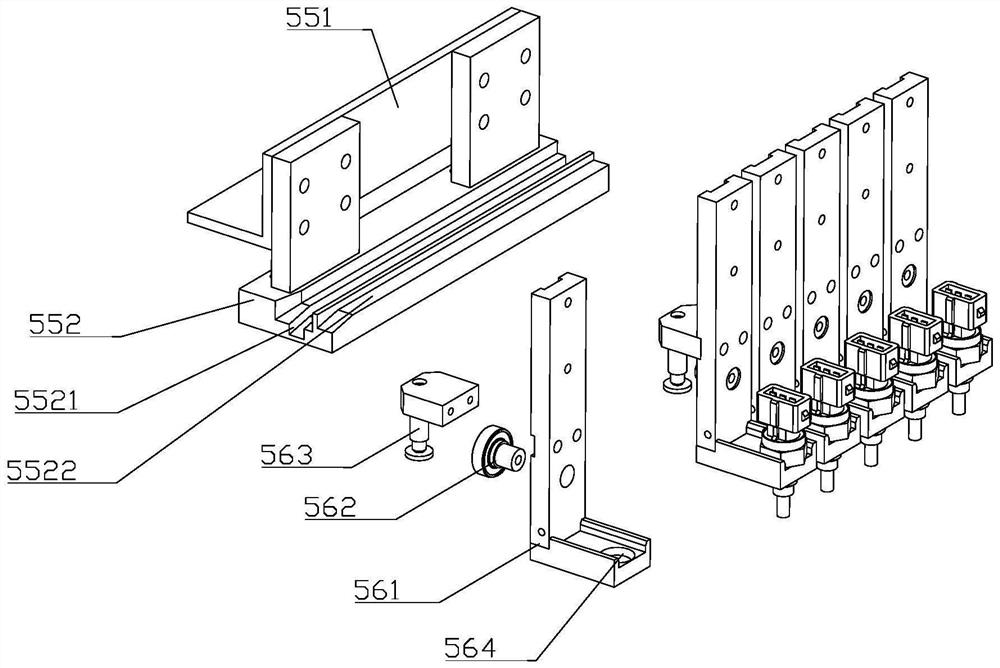

[0017] like figure 1 and 2 As shown, a temperature sensor transfer and transfer system includes a mobile material receiving assembly 4, a carrier device 5 and a transfer transfer device. The two ends of the transfer handling device correspond to the loading station and the unloading station respectively, the mobile material receiving assembly 4 is at the loading station, and the carrier device 5 is at the unloading station.

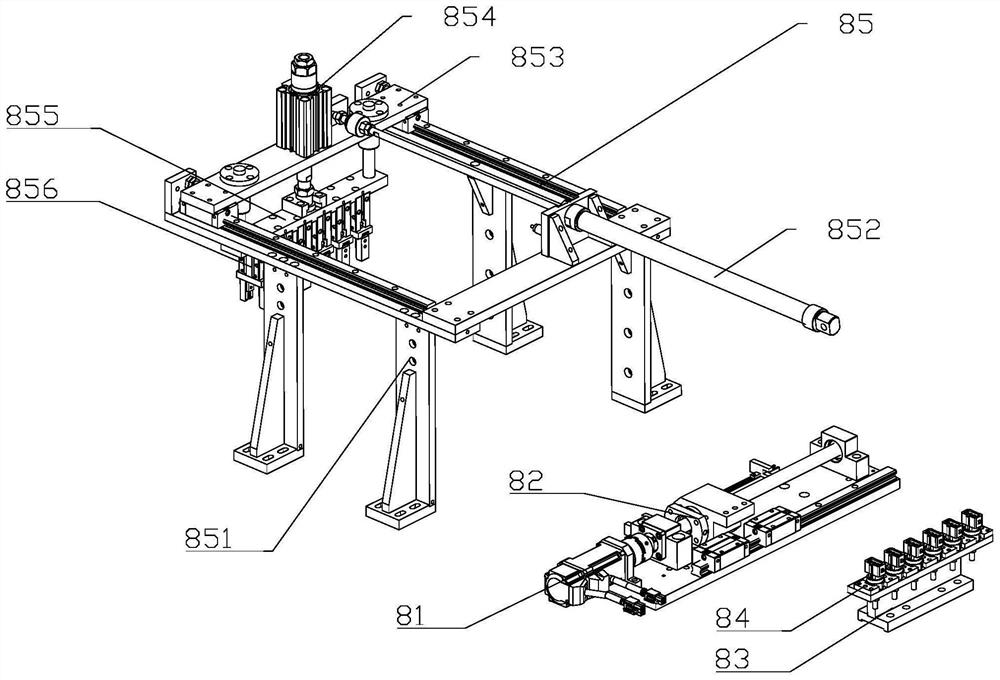

[0018] The transfer handling device includes a drive motor 81, a lead screw assembly 82, a material receiving seat 83, a backing plate 84 and an integral clamping mechanism 85; the drive motor 81 is arranged on the frame, and the drive motor 81 is connected with the lead screw assembly 82 ; The screw assembly 82 includes a screw shaft and a screw slider, the screw slider is screw-fitted on the screw shaft, and the screw slider is connected to the frame through slide rail movement; The material receiving seat 83 is elongated, and the material receiving s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com