A kind of leather processing method

A processing method, leather technology, applied in small raw hide/big raw hide/leather/fur treatment, small raw hide/big raw hide/leather/fur mechanical treatment, leather wrapping/accumulation, etc., which can solve the problem that the velvet can not be cleaned , creases on the leather surface, wrinkles in the winding section, etc., to avoid wrinkles or overlaps, improve the degree of fineness, and improve the quality of cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in many different ways that are predetermined and covered by the claims.

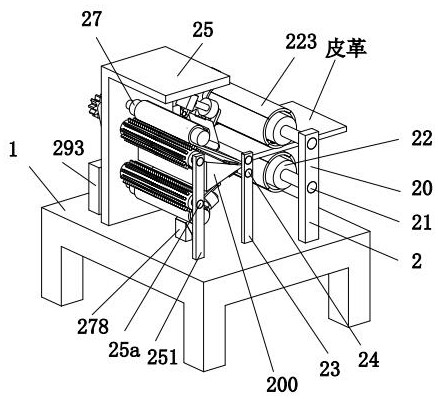

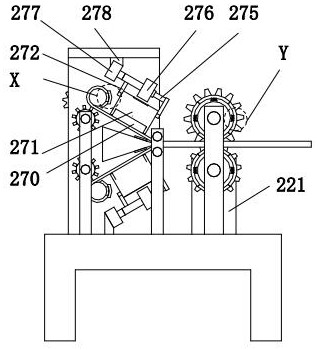

[0038] Such as Figure 1 to Figure 11 As shown, a leather processing method, which uses a leather processing device, the leather processing device includes a workbench 1 and a coiling mechanism 2, and the specific processing method when using the above-mentioned leather processing device for leather processing as follows:

[0039] S1. Pre-cutting: the leather passes through the pressure roller 22 and the transmission shaft 24 in turn and is conveyed from right to left, and the initial end of the leather is divided into two by the cutting knife 200 for pre-cutting;

[0040] S2. Initial winding and fixing: wind the leather cutting layer manually on the winding core 27, press the left end of the U-shaped clamp 28 into the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com