Piezoelectric driving type resonance air pump

A technology of piezoelectric drive and piezoelectric vibrator, applied in the direction of variable capacity pump components, pumps, pump components, etc., can solve the problem of poor gas output effect, limited deformation ability of diaphragm piezoelectric vibrator, and reduced working effect of the pump body and other problems, to achieve the effect of easy maintenance, small size and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

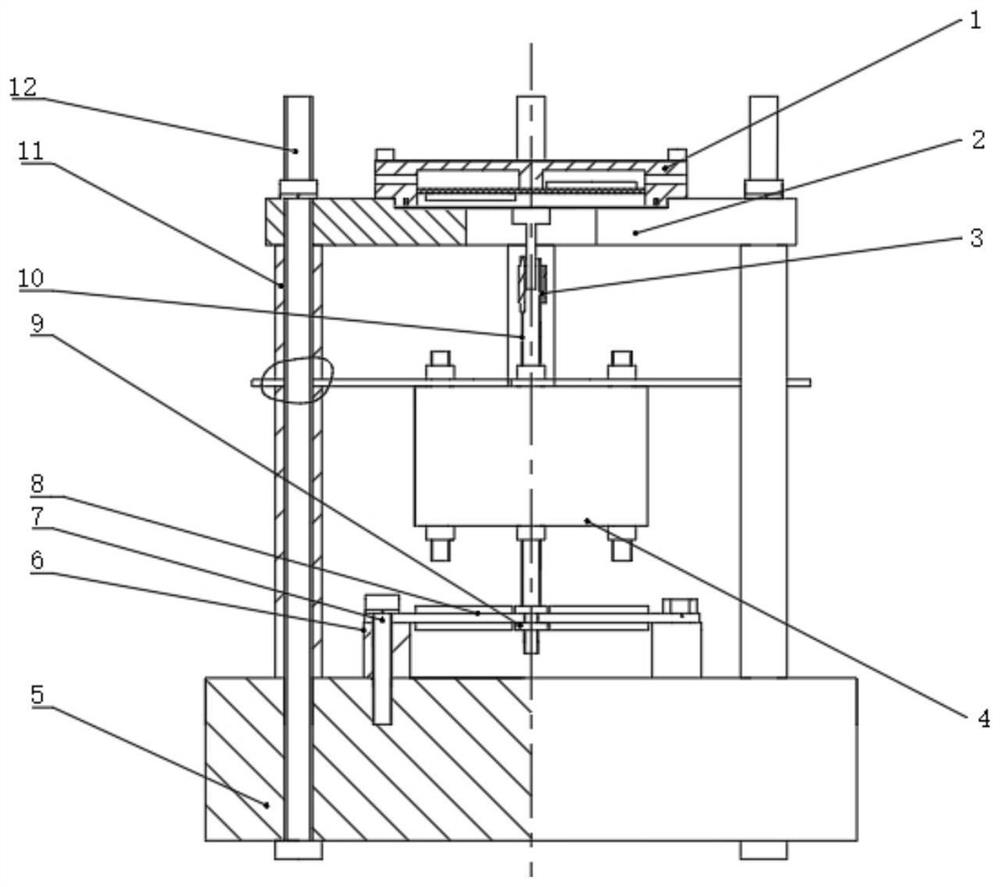

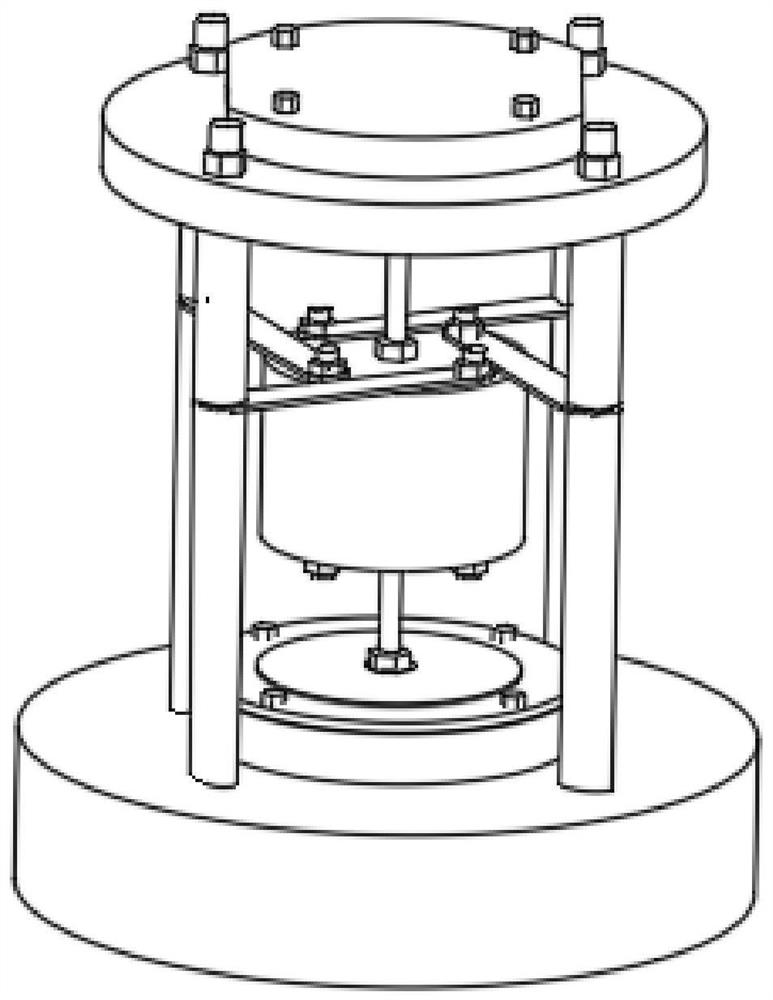

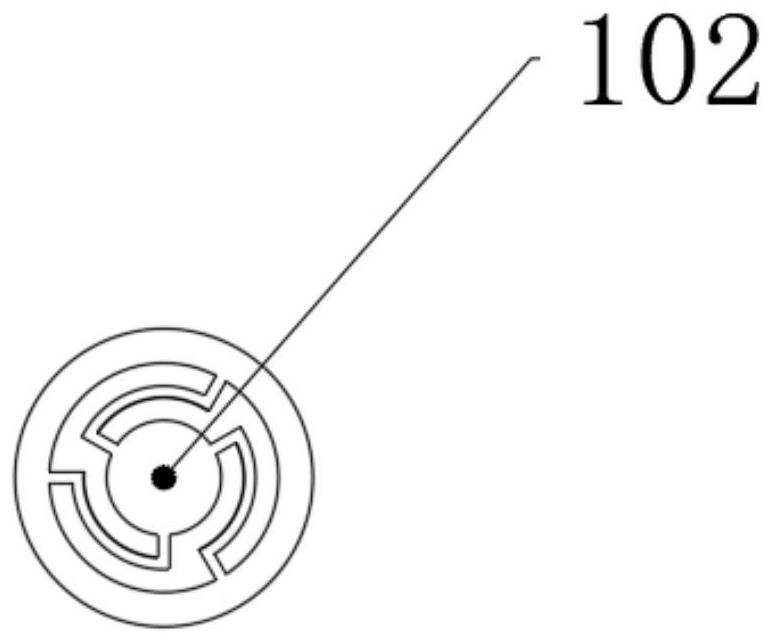

[0022] See Figure 1-5 , a piezoelectric-driven resonant air pump, including a cavity 1, a lower cavity 2 and a base 5, the base 5 is a cylindrical structure, the top of the base 5 is fixedly connected to a positioning ring 6, and the positioning ring 6 is a circular ring Shaped structure, the top of the positioning ring 6 is provided with a piezoelectric vibrator 8, the piezoelectric vibrator 8 is installed on the positioning ring 6 through a number of fastening bolts, and the top of the base 5 is evenly provided with a number of columns 11, the column 11 is a circular tubular structure, and the tops of all the columns 11 are provided with a lower cavity 2, and the lower cavity 2 is installed on the column 11 through a stud 12, and the lower cavity 2 is a circular plate structure, and the lower cavity 2 is mounted on the column 11 through a stud 12. The axis of the cavity 2 coincides with the axis of the positioning ring 6, and the top of the lower cavity 2 is provided with a...

Embodiment 2

[0025]The difference from Embodiment 1 is that the mass mechanism 4 includes a mass block 404, which is sleeved on the outside of the resonance rod 10, and the outside of the resonance rod 10 is provided with a matching mass block 404. The first nut washer 402, the top of the mass block 404 is provided with a number of spring pieces 401 in a circular array, one end of the spring piece 401 is set on the stud 12, and the other end of the spring piece 401 is installed by a mounting bolt On the mass block 404, the second nut washer 403 matched with the spring sheet 401 is sleeved on the mounting bolt, and all the spring sheets 401 are distributed in a spiral structure. By setting the spiral spring sheet 401, it can Greatly reducing the stiffness of the entire device is beneficial to reducing the natural frequency of the entire device, and can further improve the working stability of the entire device.

[0026] The working principle of Embodiment 1-2: Vibration is generated by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com