Efficient heat conduction type bay window for achieving hot spring stone plate function

A bay window and slate technology, which is applied in the field of high-efficiency heat-conducting bay windows, can solve the problems of poor heat conduction performance, poor corrosion resistance and durability performance of plastic heat medium pipes, and the surface temperature cannot exceed 30°C, so as to improve the use of value, reduce the emission speed, and increase the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

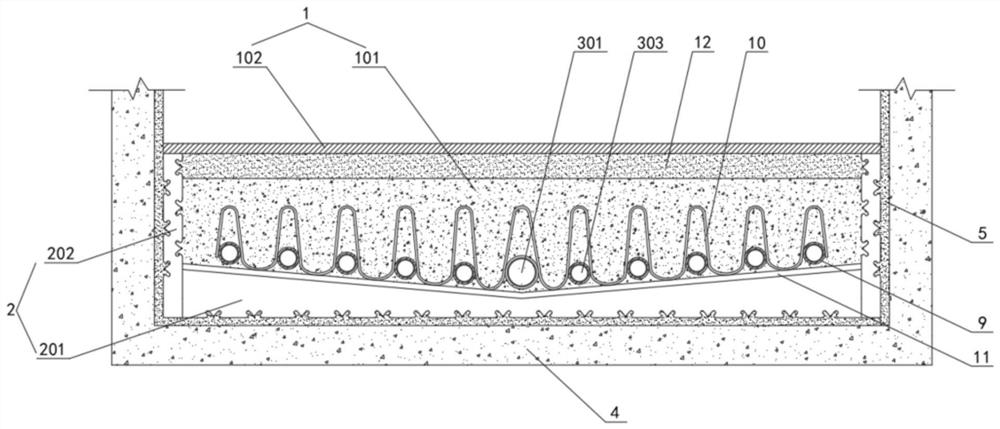

[0043] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

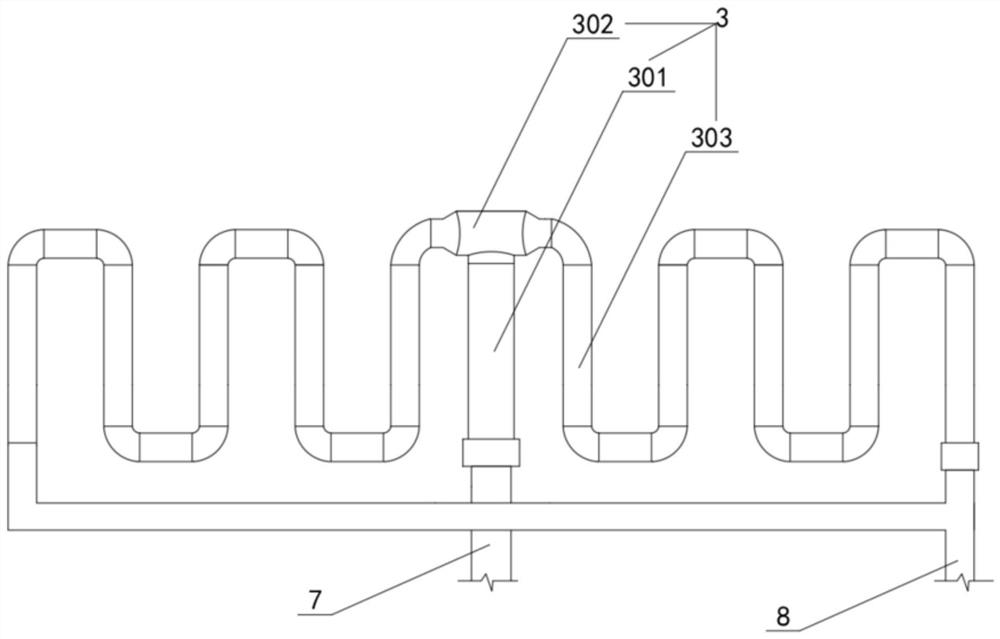

[0044] refer to Figure 1-4 , a high-efficiency heat-conducting bay window that can realize the function of a hot spring slate, including a bay window body 1, a heat insulation mechanism 2, and a heat exchange mechanism 3,

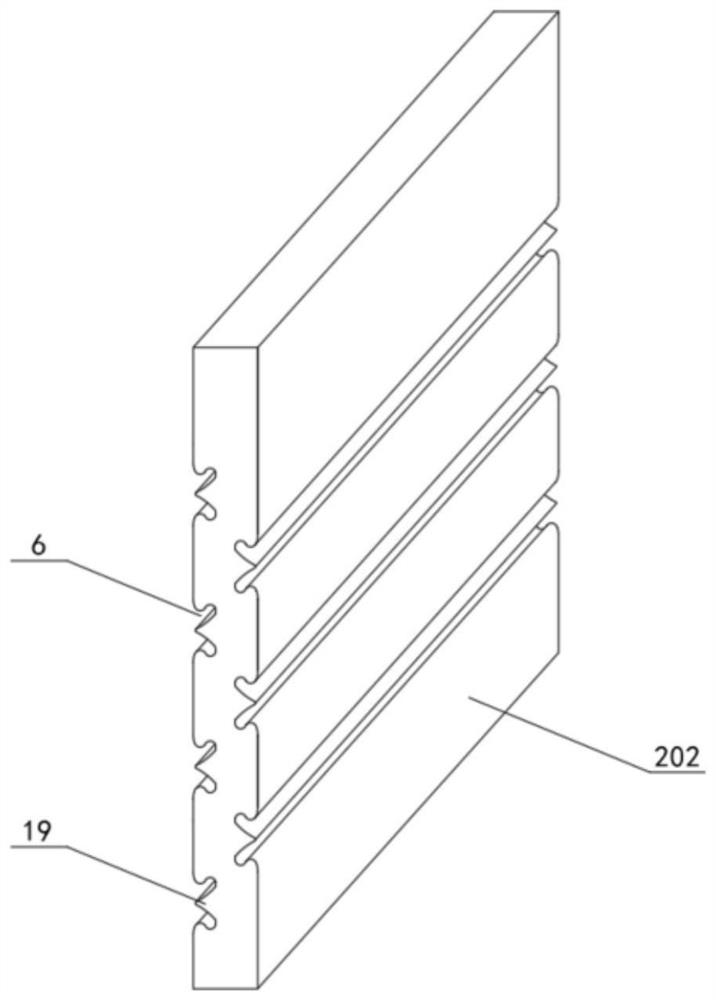

[0045] The heat insulation mechanism 2 includes a bottom heat insulation board 201 laid on the bay window bottom plate 4, and a circle of corresponding side wall heat insulation boards 202 is vertically arranged on the outer edge of the bottom heat insulation board 201. The outer walls of the heat insulation board 201 and the side wall heat insulation board 202 are respectively covered with a layer of corresponding plastering bonding layer 5;

[0046] Both the bottom heat insulation board 201 and the side wall heat insulation board 202 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com