Thyristor device

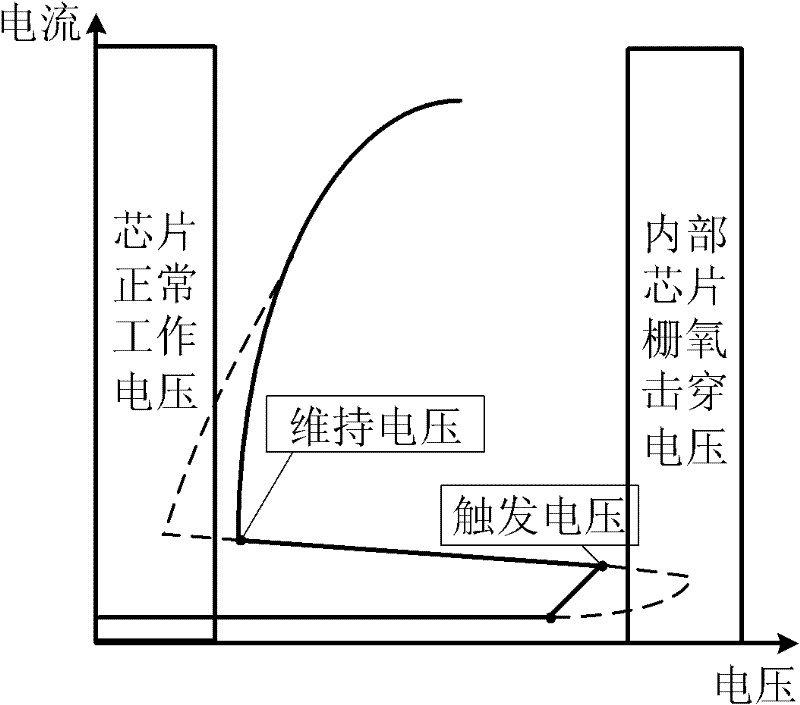

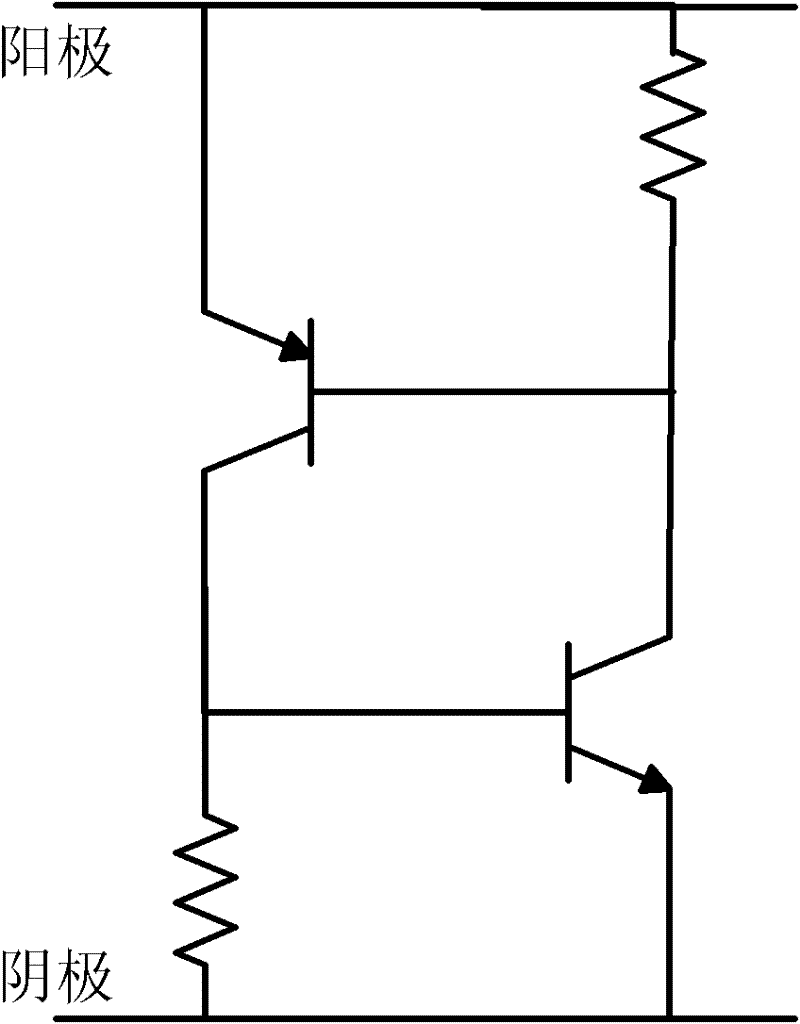

A technology of silicon devices and injection regions, which is applied in the direction of electric solid devices, semiconductor devices, electrical components, etc., can solve the problems of low maintenance voltage of thyristors, high trigger voltage of thyristors, and affecting the normal operation of chips, so as to save Layout area, reduced layout area, and good device robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited thereto.

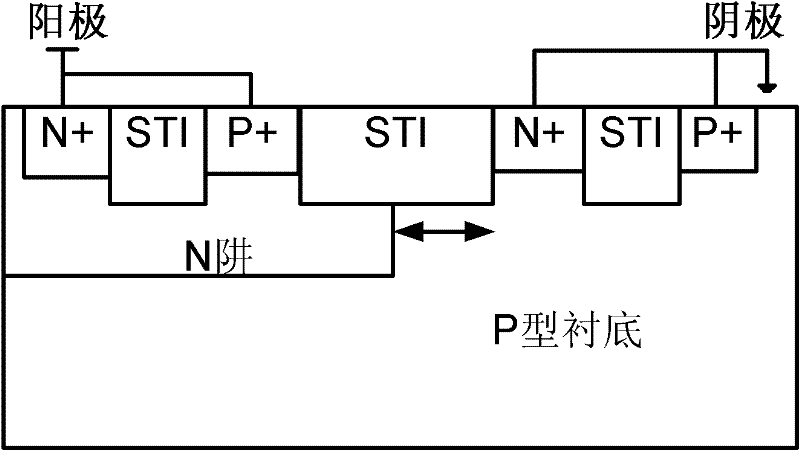

[0028] Such as Figure 4 and Figure 5 As shown, a thyristor device includes a P-type substrate 41, and a first N well 42 connected to the electrical anode and a second N well 43 with a floating potential are arranged on the P-type substrate 41 along the lateral direction. The N well 42 and the second N well 43 are not connected;

[0029] From the first N well 42 to the direction of the second N well 43, in the first N well 42, the second N well 43 and the area where no N well is set on the P-type substrate 41, the first N+ Implantation region 44, first P+ implantation region 45, third N+ implantation region 49, second N+ implantation region 46 and second P+ implantation region 47;

[0030] Wherein, the first N+ implantation region 44 and the first P+ implantation region 45 are arranged in the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com