Tree canopy thickness detection method based on ultrasonic echo signals

A technology of ultrasonic echo and detection method, which is applied in the field of agricultural machinery information sensing and detection, and can solve the problems of tree canopy thickness error and poor applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

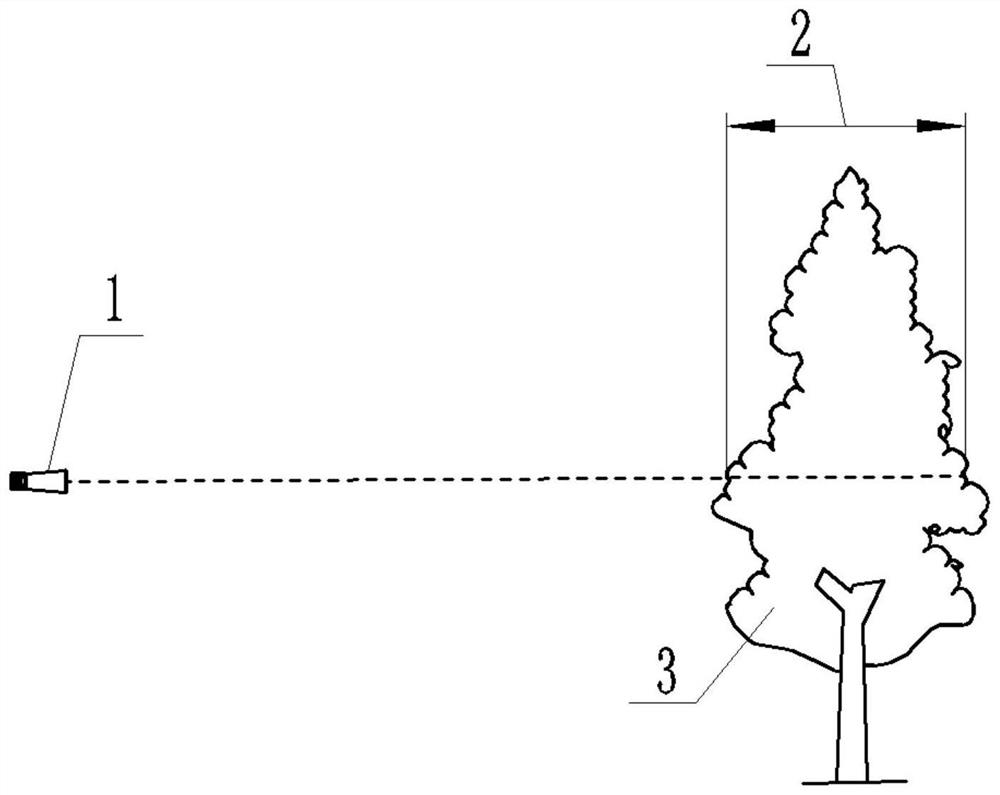

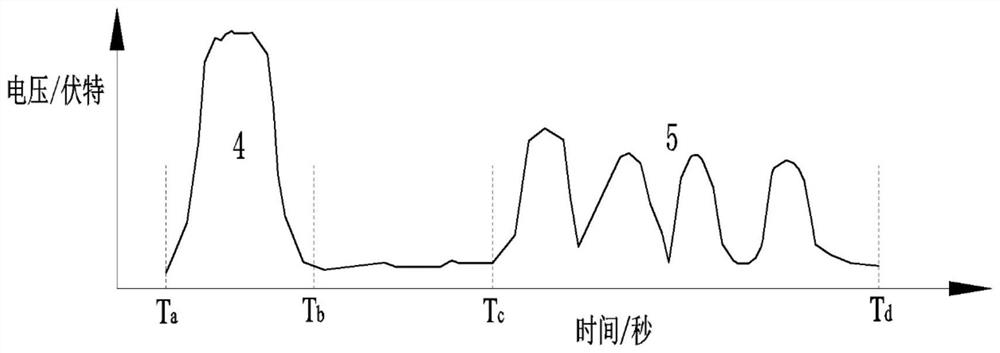

[0022] Such as figure 1 As shown, it is a schematic diagram of an ultrasonic sensor detecting the thickness of the tree canopy provided by an embodiment of the present invention. The ultrasonic sensor 1 sends an ultrasonic transmission signal 4 facing the tree canopy 3, and the tree canopy 3 is reflected to form an ultrasonic echo signal 5. The tree canopy thickness 2 along the ultrasonic detection direction emitted by the ultrasonic sensor 1 is as follows: figure 1 shown.

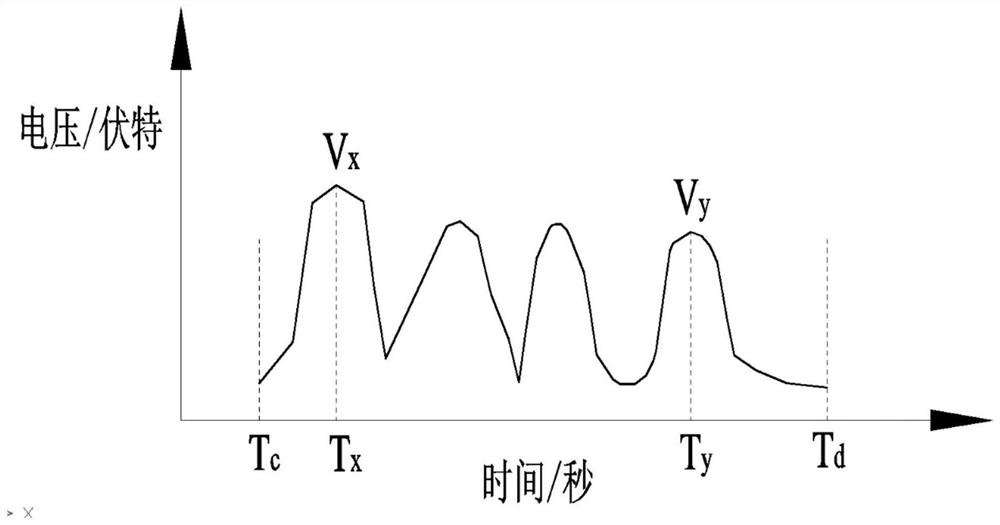

[0023] Typical ultrasonic transmission signal 4 and ultrasonic echo signal 5 such as figure 2 As shown, the ultrasonic transmission signal 4 and the ultrasonic echo signal 5 are composed of voltage data and corresponding time data within a certain period of time, wherein the ultrasonic transmission signal 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com