Automatic packaging method integrating two-dimensional code scanning and terminal

A technology of two-dimensional code and code scanning, which is applied to the automatic packaging method and terminal field of integrated two-dimensional code scanning, which can solve the problem of long waiting time for packaging, packers who fail to scan the code in time, long waiting time in the packaging task queue, and labor-intensive Time cost and other issues, to reduce the frequency of manual intervention packaging and manual code scanning, save labor costs, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

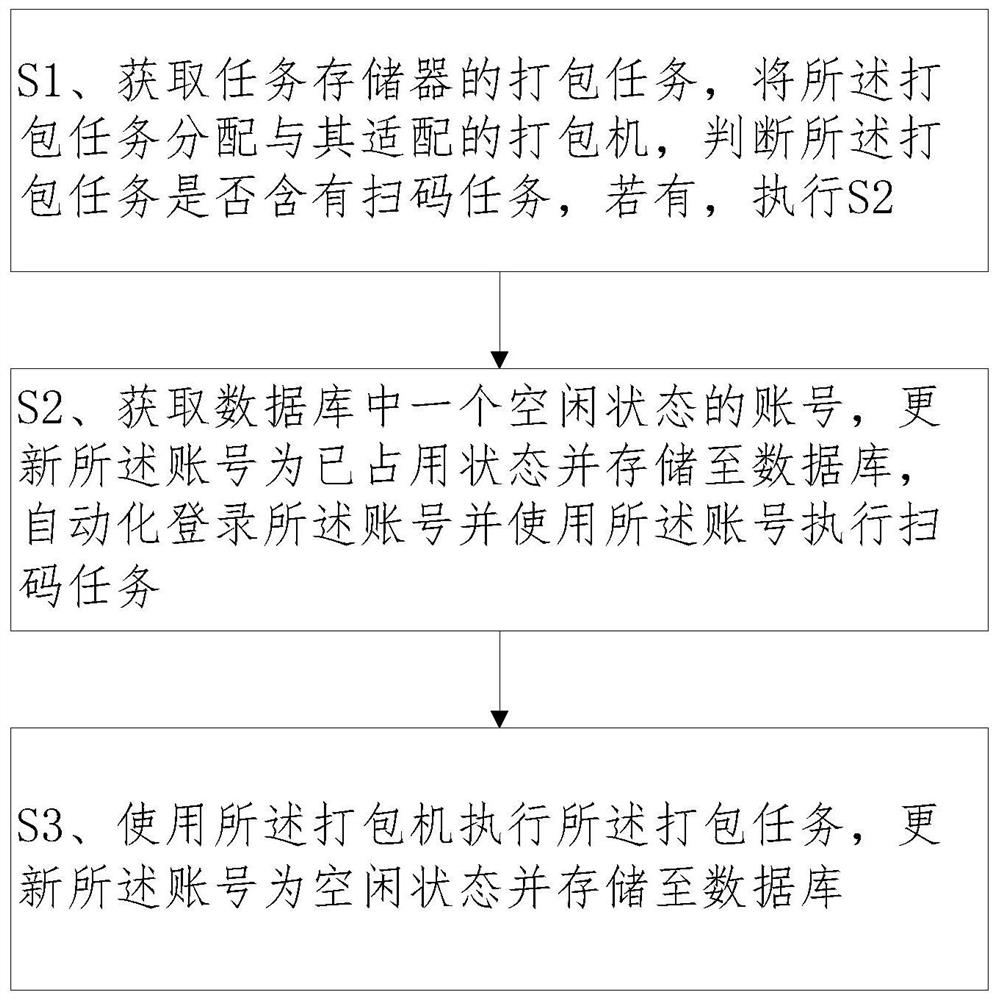

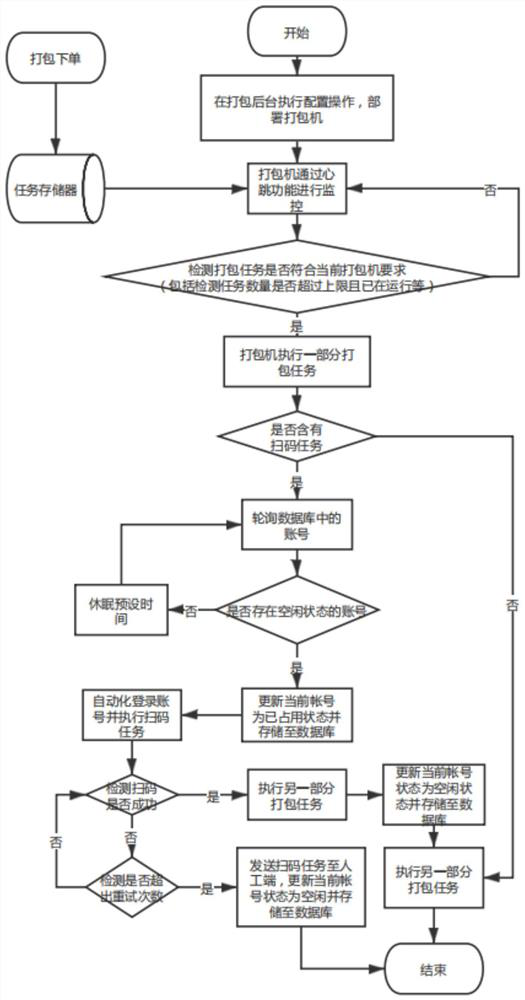

[0072] Please refer to figure 1 with image 3 As shown, an automatic packaging method integrating two-dimensional code scanning, including:

[0073] S00. Configure product and business-related configurations in the packaging background, for example: product information (product name, AppID, icon, version number, etc.); project information (Git warehouse address, branch, compiler version, etc.); market information (channel, Advertising Key, etc.); business configuration (packaging method, etc.); account configuration required for scanning codes, etc.

[0074] S01. Deploy a packer server cluster (or a single packer), and enable the heartbeat detection function;

[0075] S0, storing the packaging task in the task memory, and the packaging machine monitors the packaging task through the heartbeat detection function;

[0076] S1. Obtain the packaging task of the task memory, assign the packaging task to a packaging machine adapted to it, and judge whether the packaging task cont...

Embodiment 2

[0092] Please refer to figure 2 , an automatic packaging terminal 1 integrating two-dimensional code scanning, comprising a memory 2, a processor 3, and a computer program stored in the memory 2 and operable on the processor 3, the processor 3 executing the computer program When implementing the steps in the first embodiment.

[0093] In summary, the present invention provides an automatic packaging method and terminal that integrates two-dimensional code scanning. When the user executes the packaging and ordering operation, he can enter the automatic packaging process, that is, he can automatically assign the packaging task to the packaging machine, and the packaging The machine automatically executes the packaging task. When there is a code scanning task in the packaging task, the idle account can be used to perform the scanning task before performing the packaging task. Therefore, the present invention can simplify the packaging and code scanning process, reduce the frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com