Characterization method of asphalt nanoscopic aggregation state

A technology of aggregate state and asphalt, which is applied in the field of characterization of nano-scale aggregate state of asphalt, which can solve the problems of complex molecular species and difficult chemical structure of asphalt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

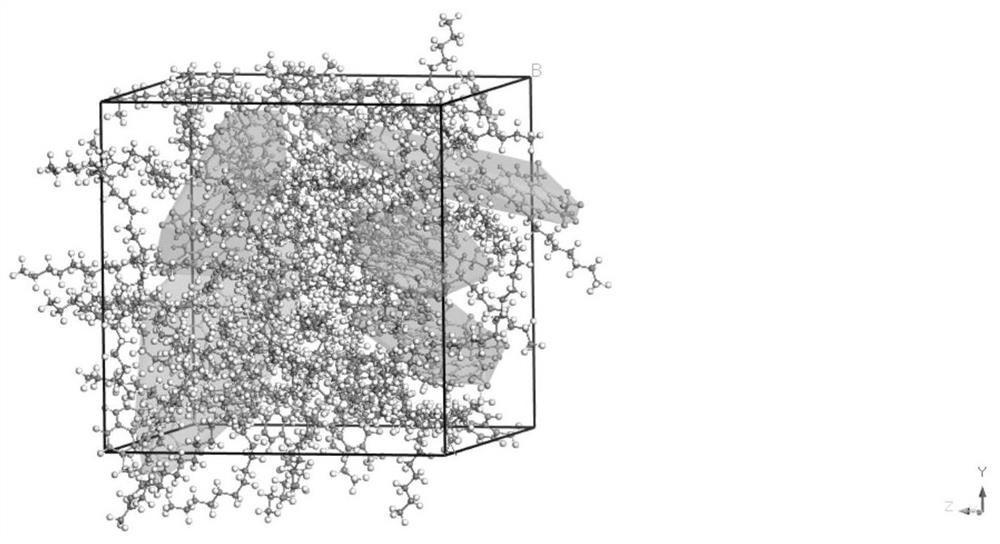

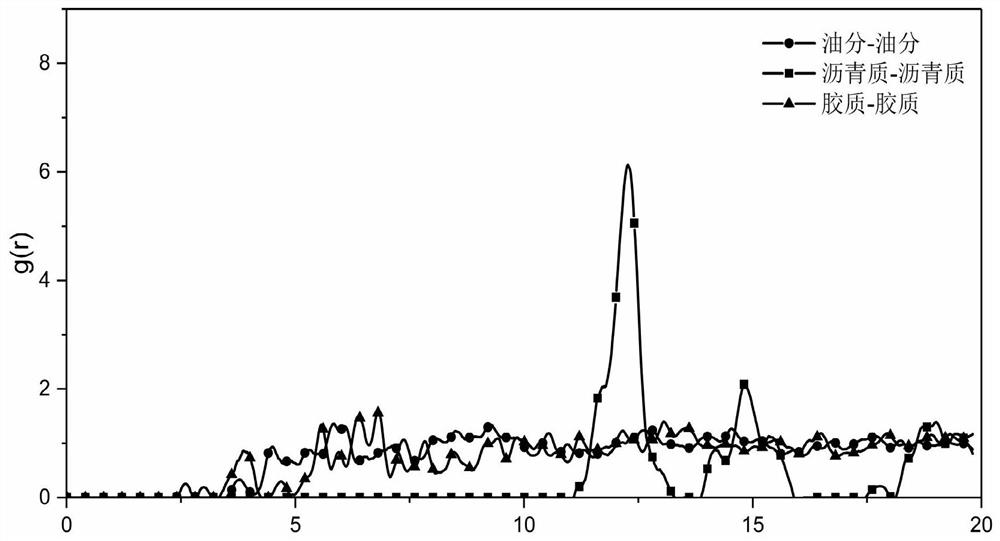

[0050] At T=298K, the effect of SBS modifier on the nanoscopic aggregation state of asphalt was evaluated. The centroid radial distribution functions of asphaltene, oil, and colloids of ordinary asphalt and SBS modified asphalt after smoothing are obtained as follows: figure 1 , 2 shown.

[0051] The aggregation of asphaltene molecules is characterized by the ratio of the sum of the 0.8-2nm asphaltene-colloid radial distribution function to the sum of the 0.8-2nm asphaltene-oil radial distribution function, as shown in image 3 shown.

[0052] It can be seen from the figure that the SBS modifier has a certain influence on the aggregation state of asphalt molecules at T=298K. The specific performance is: compared with ordinary asphalt molecules, there is no significant change in the aggregation of colloid molecules in SBS asphalt molecules. The molecular distribution is more uniform; the colloidal structure formed between asphaltene and pectin is more uniform.

Embodiment 2

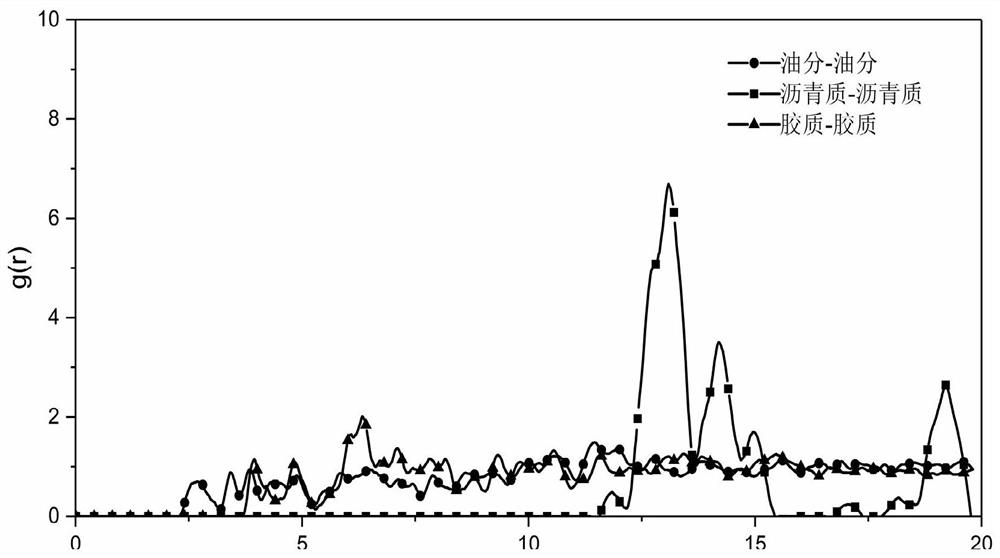

[0054] The nanoscopic aggregation state of SBR modified asphalt was characterized at T=358K. The centroid radial distribution function of asphaltene, oil and colloid of SBR modified asphalt after smoothing treatment is obtained as Figure 4 shown.

[0055] Such as Figure 5 As shown, the asphaltene nano-aggregation state of SBR modified asphalt presents an obvious layered structure.

[0056] The aggregation of asphaltene molecules is characterized by the ratio of the sum of the 0.8-2nm asphaltene-colloid radial distribution function to the sum of the 0.8-2nm asphaltene-oil radial distribution function, as shown in Figure 6 shown.

Embodiment 3

[0058] The effect of SBS-MAH modifier on asphalt nano-aggregation state was evaluated at T=418K. The centroid radial distribution function of the smoothed SBS-MAH modified asphaltene, oil and colloid is obtained as follows: Figure 7 shown.

[0059] The aggregation of asphaltene molecules is characterized by the ratio of the sum of the 0.8-2nm asphaltene-colloid radial distribution function to the sum of the 0.8-2nm asphaltene-oil radial distribution function, as shown in Figure 8 shown.

[0060] It can be seen from the figure that the SBS-MAH modifier has a certain influence on the aggregation state of asphalt molecules at T=418K. The specific performance is: compared with ordinary asphalt molecules, the aggregation of oil molecules in SBS-MAH asphalt molecules is more significant, and the asphaltene 1. There was no significant change in the distribution of colloid molecules; there was no significant change in the colloidal structure formed between asphaltenes and colloids...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com