Radial multidirectional dispersed sound-absorbing material

A sound-absorbing material and radiation-type technology, applied in the field of sound-absorbing materials, can solve the problems of passive sound absorption effect, hindered sound transmission, poor sound absorption efficiency, etc., and achieve the effect of improving sound absorption and noise reduction, reducing transmission speed and good sound absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

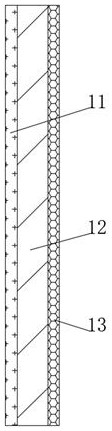

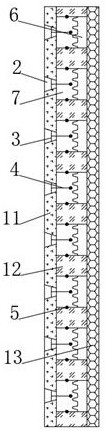

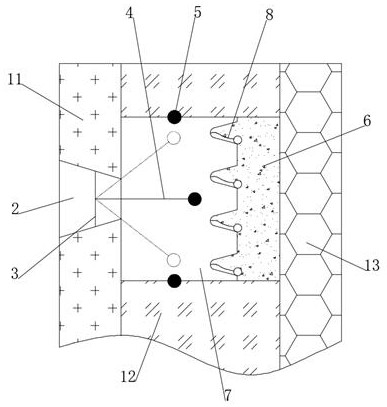

[0039] see figure 1 , a radial multidirectional dispersed sound-absorbing material, comprising an outer sound-collecting layer 11, a differentiated interlayer 12, and a sound-absorbing hole layer 13, the outer sound-collecting layer 11, the differentiated interlayer 12, and the sound-absorbing hole layer 13 are distributed sequentially from outside to inside, and Two pairs that are close to each other are fixedly connected.

[0040] see Figure 2-3 The surface of the outer sound collecting layer 11 is dug with a plurality of evenly distributed sound collecting holes 2, the middle part of the sound collecting holes 2 is fixedly connected with a vibrating diaphragm 3, and the end of the vibrating diaphragm 3 facing the differentiated interlayer 12 is fixedly connected with a slow vibrating rod 4 The middle part of the differentiation interlayer 12 is excavated with a plurality of differentiation cavities 7 corresponding to the sound collection holes 2, the slow vibrating rod 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com