Display panel and manufacturing method thereof and display device

A display panel and display area technology, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., and can solve problems such as the inability to realize a full screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

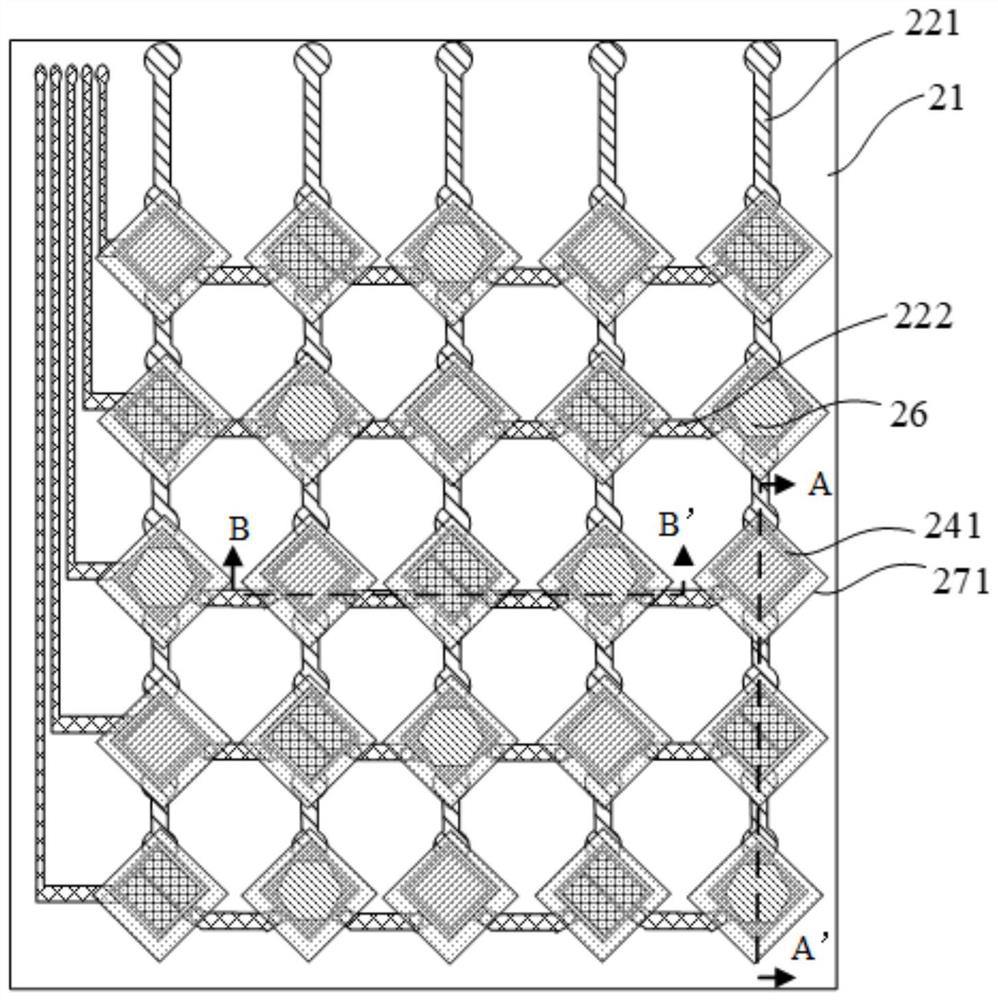

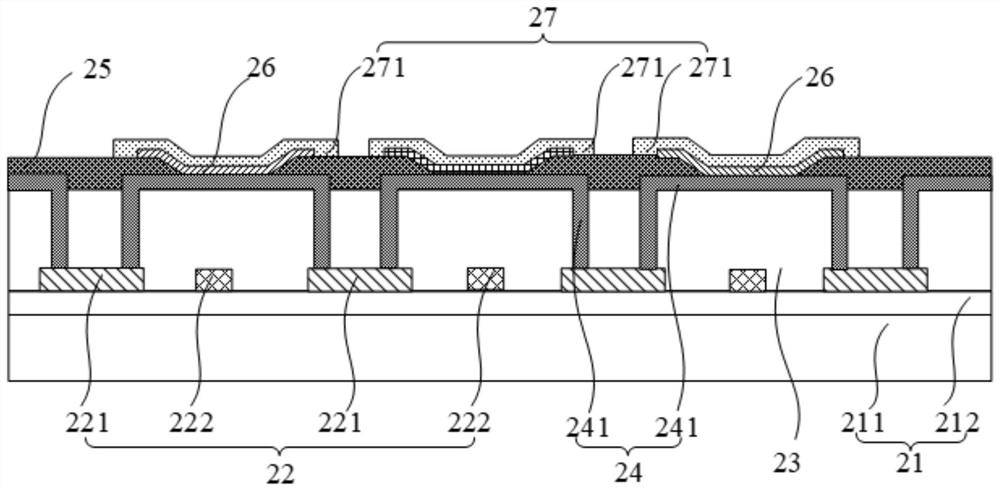

[0053] refer to figure 1 , showing a schematic diagram of a display panel according to an embodiment of the present invention, figure 2 shows a planar structure diagram of a functional display area in a display panel according to an embodiment of the present invention, image 3 show figure 2 A cross-sectional view of the shown display panel along section A-A', Figure 4 show figure 2 The shown display panel is a cross-sectional view along section B-B'.

[0054] The embodiment of the present invention provides a display panel, including: a substrate 21, the substrate 21 is divided into the effective display area 10 and the functional display area 20 where the functional device 30 is located; The electrode connection layer 22, the electrode connection layer 22 includes a plurality of mutually insulated anode connection lines 221 and cathode connection lines 222, and the anode connection lines 221 are distributed along the first direction, and the cathode connection lines ...

Embodiment 2

[0098] refer to Figure 6 , which shows a flow chart of a method for manufacturing a display panel according to an embodiment of the present invention, which may specifically include the following steps:

[0099] Step 601, providing a substrate; the substrate is divided into an effective display area and a functional display area where functional devices are located.

[0100]In the embodiment of the present invention, first, a substrate 21 is fabricated, and the substrate 21 is divided into an effective display area 10 and a functional display area 20 where the functional device 30 is located.

[0101] Specifically, an active layer, a gate insulating layer, and a gate layer are respectively formed on the effective display area 10 of the substrate 211, and then an interlayer dielectric layer is formed on both the effective display area 10 and the functional display area 20, and then, in the effective display area A source-drain electrode layer is formed on the interlayer diele...

Embodiment 3

[0128] An embodiment of the present invention provides a display device, including a functional device 30 and the above-mentioned display panel;

[0129] Wherein, the functional device 30 includes devices such as a camera and a sensor.

[0130] For the specific description of the display panel, reference may be made to the descriptions of Embodiment 1 and Embodiment 2, which will not be repeated in this embodiment of the present invention.

[0131] In addition, the display device also includes devices such as a driver chip and a TCON (Timer Control Register, timing controller).

[0132] In practical applications, the display device may be any product or component with a display function such as a mobile phone, a tablet computer, a monitor, a notebook computer, or a navigator.

[0133] In the embodiment of the present invention, the electrode connection layer, flat layer, anode layer, pixel defining layer, organic functional layer and cathode layer are sequentially arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com