Corrosion measurement device

A technology for equipment and objects, applied in the field of electrochemical battery devices, which can solve the problems of unsuitable sensors, unsuitable sensors for applications, and long processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

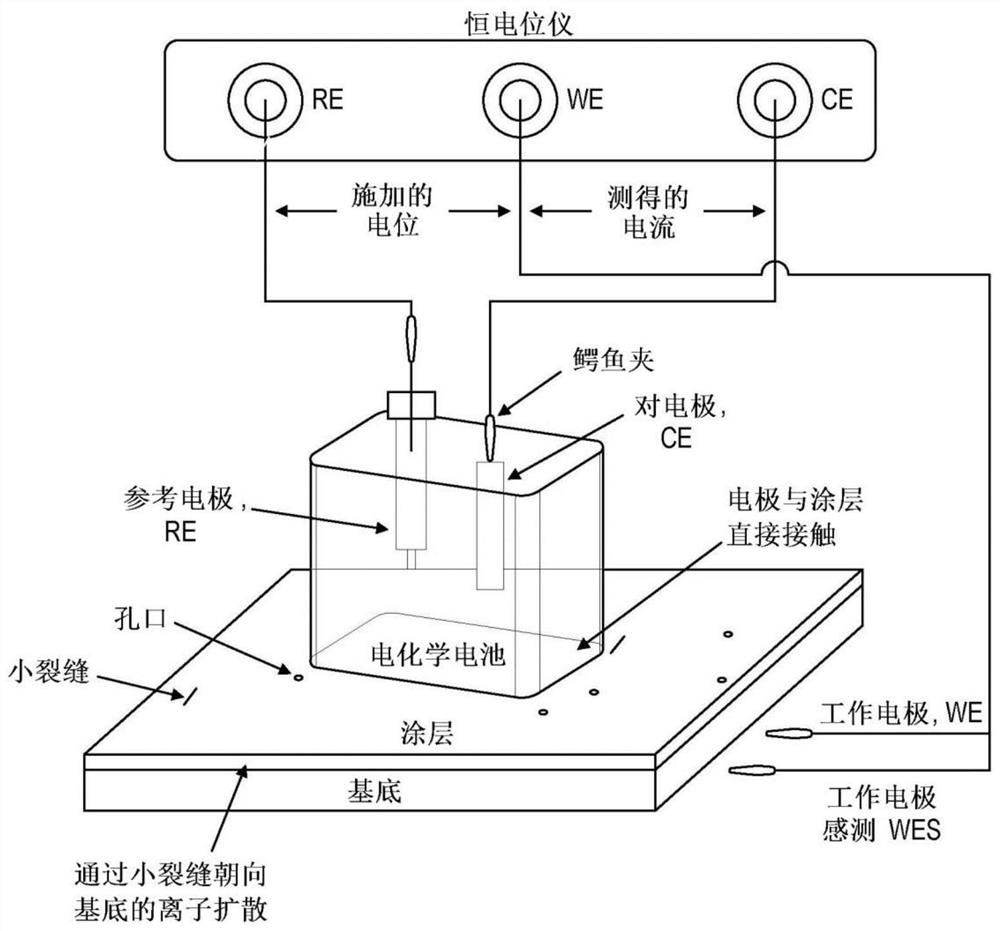

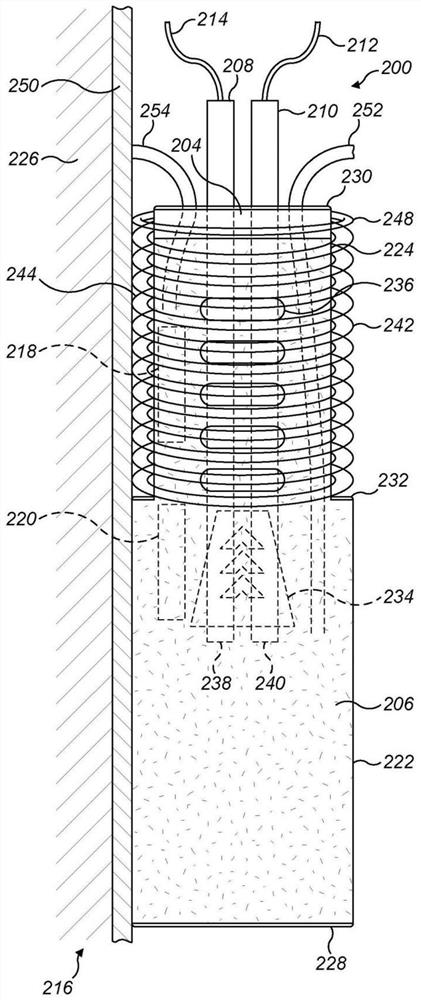

[0072] refer to figure 2 , examples of devices for sensing electrochemical changes in objects will now be described. In this example, the device is a two-electrode electrochemical cell device 200 . The electrochemical cell device 200 has a substantially electrically conductive body in the form of a cell device housing 202 . The battery device housing 202 defines a cavity 204 which, in use, is filled with an electrolyte 206 . The electrochemical cell arrangement 200 also has a first electrode in the form of a counter electrode 208 . In this example, the electrochemical cell arrangement 200 also has a second electrode in the form of a reference electrode 210 . The electrodes are located within chamber 204 and are connected to cables 212 and 214 for electrical connection to a potentiostat or galvanostat when electrochemical cell device 200 is used to sense electrochemical changes in object 216 . In this example, battery device housing 202 contains two magnets 218 and 220 that a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com