Self-falling type efficient concrete mixer

A concrete mixer, self-falling technology, applied in cement mixing equipment, clay preparation equipment, grain processing, etc., can solve the problems of poor mixing effect and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

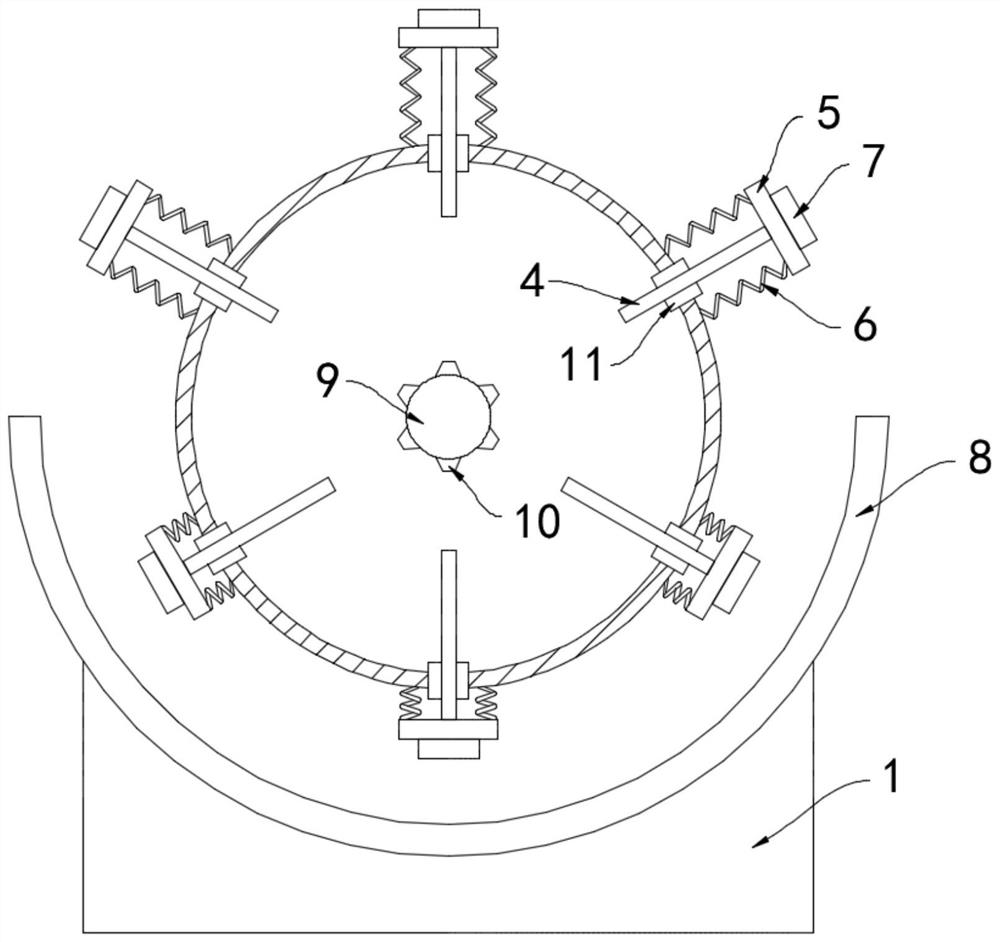

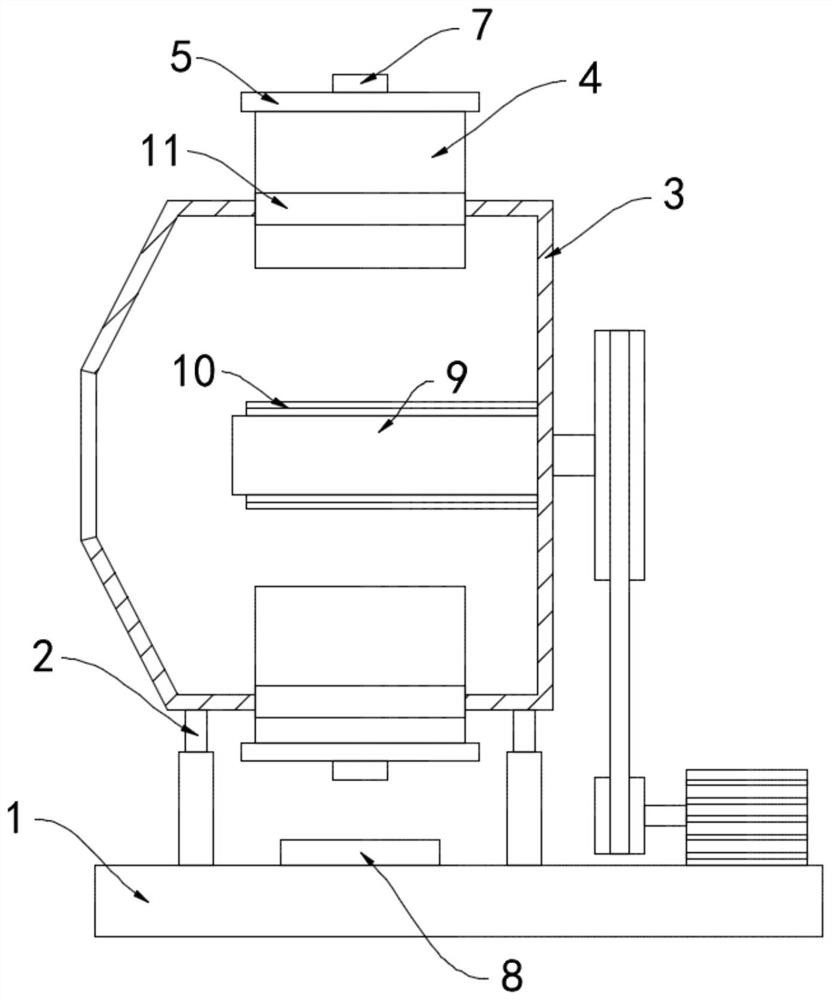

[0020] like Figure 1-2 As shown, a self-falling high-efficiency concrete mixer includes a base 1, and the upper end of the base 1 is connected to a rotating cylinder 3 through a support wheel 2. The rotating cylinder 3 is provided with a plurality of movable plates 4 arranged in the radial direction. The movable plate 4 is arranged in an annular array, the movable plate 4 runs through the side wall of the rotating cylinder 3 and is slidably connected with the rotating cylinder 3, and a sealing strip 11 is slid on the side wall of the movable plate 4, and the sealing strip 11 is fixedly connected with the rotating cylinder 3 to enhance The sealing effect between the movable plate 4 and the rotating cylinder 3 prevents the concrete from flowing out.

[0021] One end of the plurality of movable plates 4 is fixedly connected with a fixed plate 5, the side wall of the fixed plate 5 and the rotating cylinder 3 is fixed by a spring 6, and a magnet block 7 is installed on the side wa...

Embodiment 2

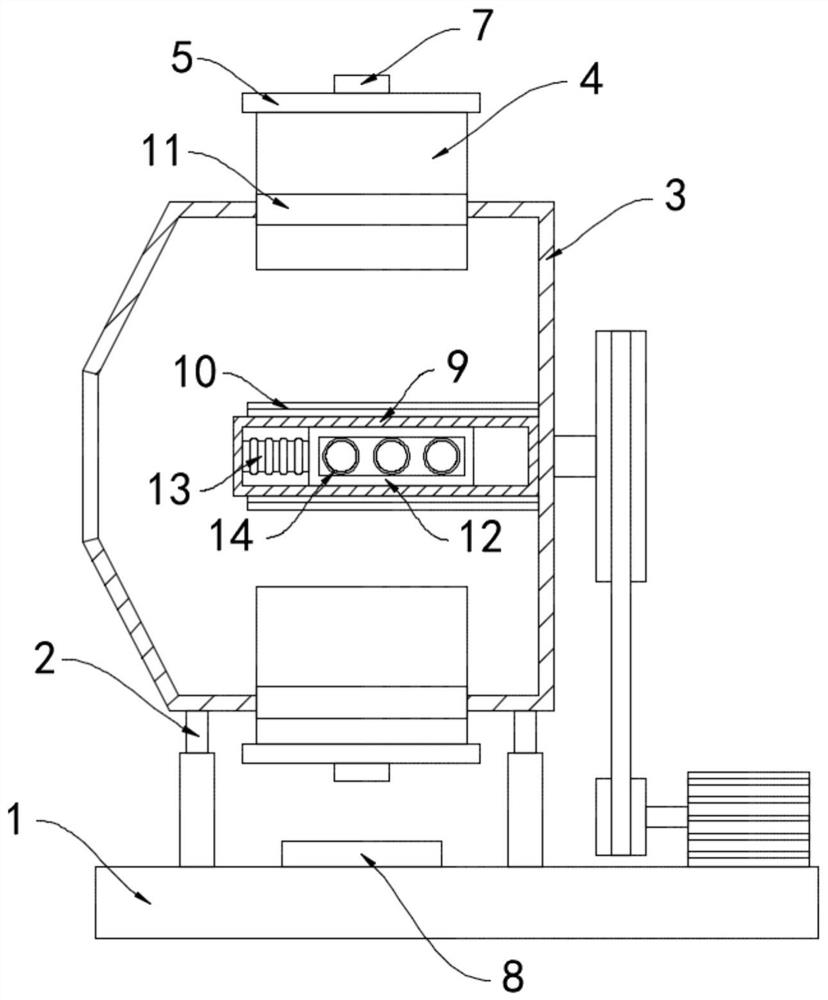

[0024] like image 3 As shown, the difference between this embodiment and Embodiment 1 is that: a thermal conduction frame 12 is slidably connected in the crushing cylinder 9, and the thermal conduction frame 12 is fixed to the end of the crushing cylinder 9 through a telescopic air bag 13, and the telescopic air bag 13 is filled with heat For expansion and contraction medium, a plurality of conductive coils 14 are fixedly connected in the heat conduction frame 12 , and the conductive coils 14 are arranged parallel to the axial direction of the crushing cylinder 9 .

[0025] In this embodiment, when the crushing cylinder 9 rotates with the rotating cylinder 3, the heat conducting frame 12 and the conductive coil 14 rotate with the crushing cylinder 9. According to the principle of electromagnetic induction, when the magnetic flux in the closed coil changes, a Inductive current, then the magnetic flux generated by the permanent magnetic strip 8 in the conductive coil 14 changes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com