Automatic material-dividing switching device

A conversion device, automatic technology, applied in the direction of transportation and packaging, loading/unloading, conveyor objects, etc., can solve the problems of complex control system, residual raw material powder, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

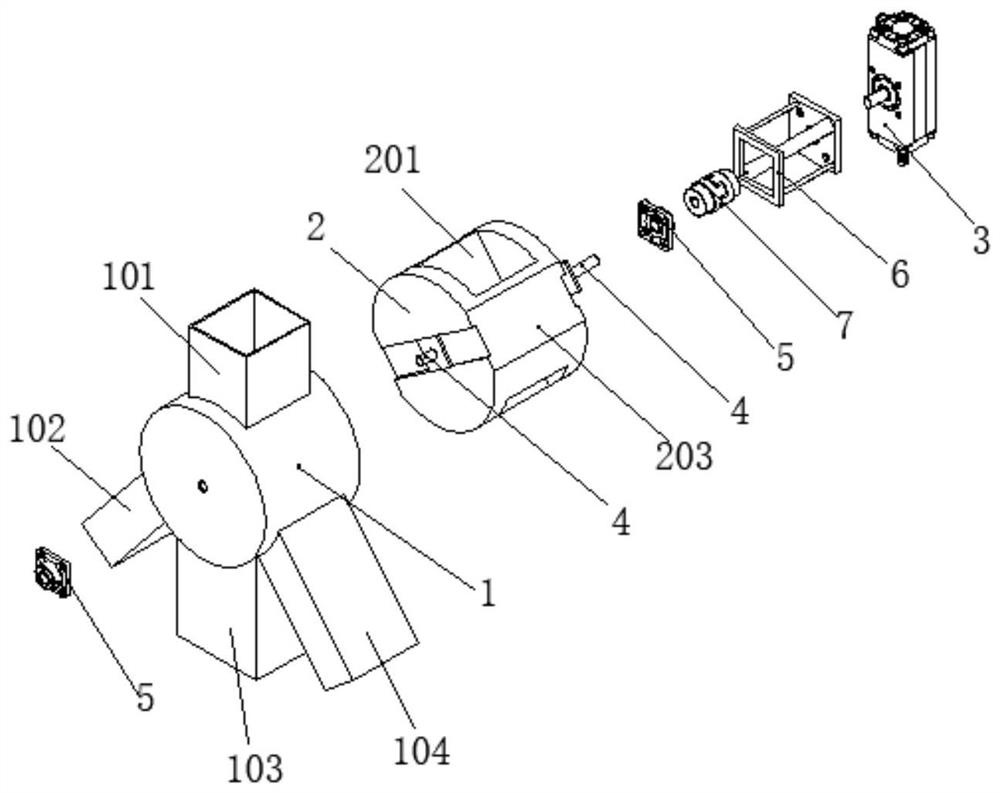

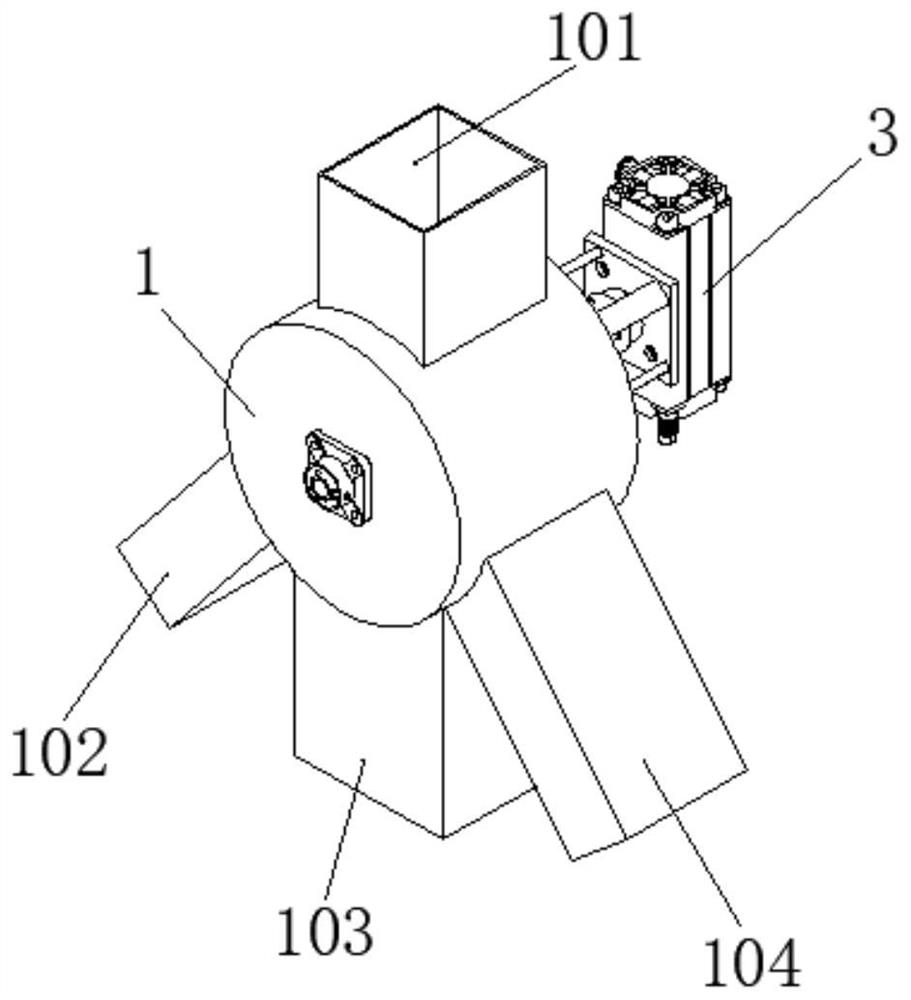

[0025] Such as Figure 1-8 As shown, this embodiment includes a material distribution housing 1, a material distribution rotor 2 arranged in the material distribution housing 1, and a rotating cylinder 3 connected to the material distribution rotor 2, and the seated shaft 4 is assembled on both ends of the material distribution rotor 2. end, and is fixed on the material distribution shell 1 through the bearing with seat 5, so that the material distribution rotor 2 can rotate freely in the material distribution shell 1; the cylinder fixed seat 6 is connected with the rotating cylinder 3, and the cylinder fixed seat 6 is fixed on the On the material housing 1, the rotating cylinder 3 is connected to the belt shaft seat 4 fixed on the material distribution rotor 2 through a coupling 7, and the belt bearing seat 5 is located between the belt shaft seat 4 and the coupling 7, and the rotating cylinder 3 controls the rotation of the material distribution rotor 2, and controls the rot...

Embodiment 2

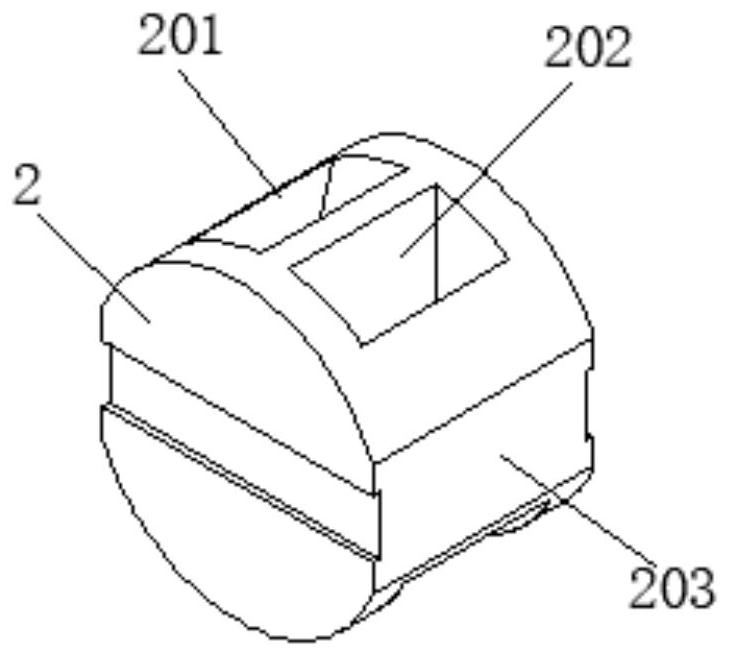

[0029] Such as Figure 7-9 As shown, in this embodiment, the distributing rotor 2 is provided with a through passage, the longitudinal section of which is conical, and the cross-sectional area of the upper end surface of the through passage is larger than the cross-sectional area of the feed port 101, and the distributing rotor 2 goes toward the single The angle of side swing is 30°, and within one swing cycle, the end of the through channel close to the feed port 101 is always connected with the feed port 101, that is, when the distributing rotor 2 swings counterclockwise to the limit position, the penetrating passage The left side of the upper end of the channel will be on the same straight line as the left side of the lower end of the discharge port 101, and the lower end of the through channel will be connected with the first discharge port 102; It is located on the same straight line as the right side of the lower end of the discharge port 101, and the lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com