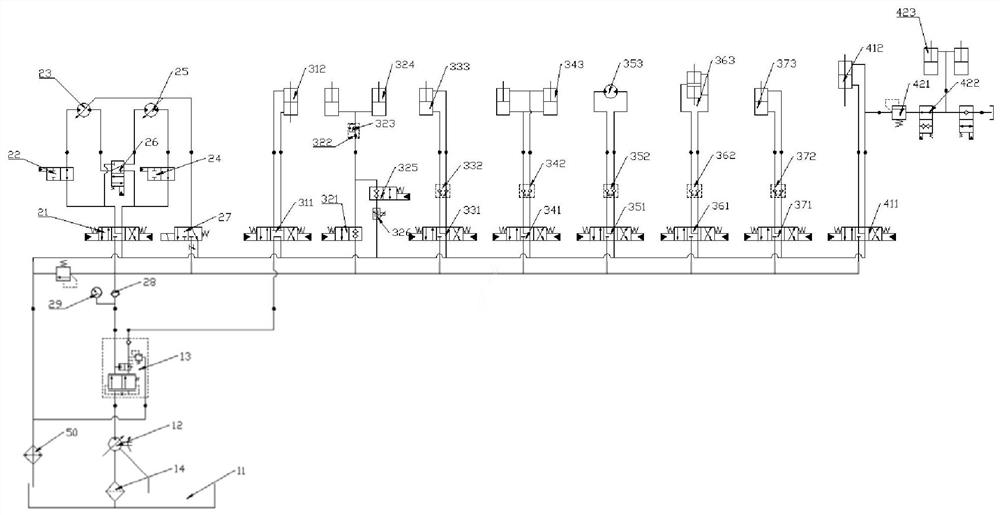

Hydraulic control system of iron making blast furnace repairing and dismounting robot

A technology of hydraulic control system and iron-making blast furnace, which is applied in the direction of fluid pressure actuation system components, lifting devices, mechanical equipment, etc., can solve the problems of air jacket welding, single function, heavy blast furnace air jacket weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In the following, only some exemplary embodiments are briefly described. As those skilled in the art would realize, the described embodiments may be modified in various different ways, all without departing from the spirit and scope of the present invention. Accordingly, the drawings and descriptions are to be regarded as illustrative in nature and not restrictive.

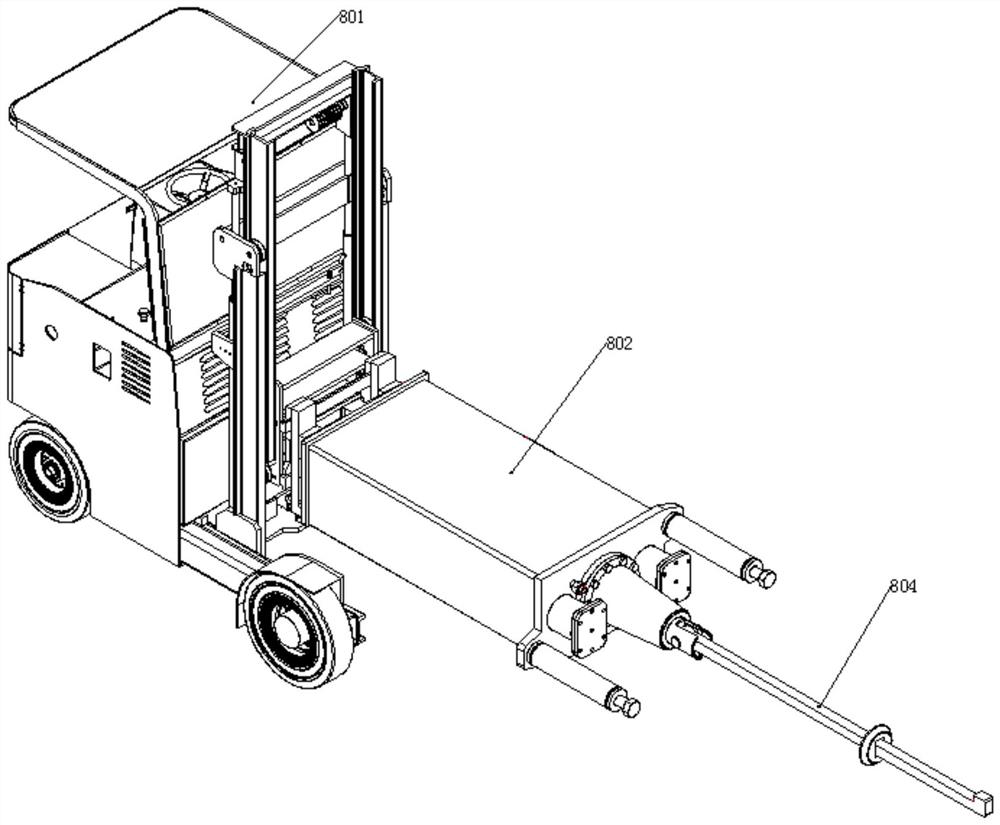

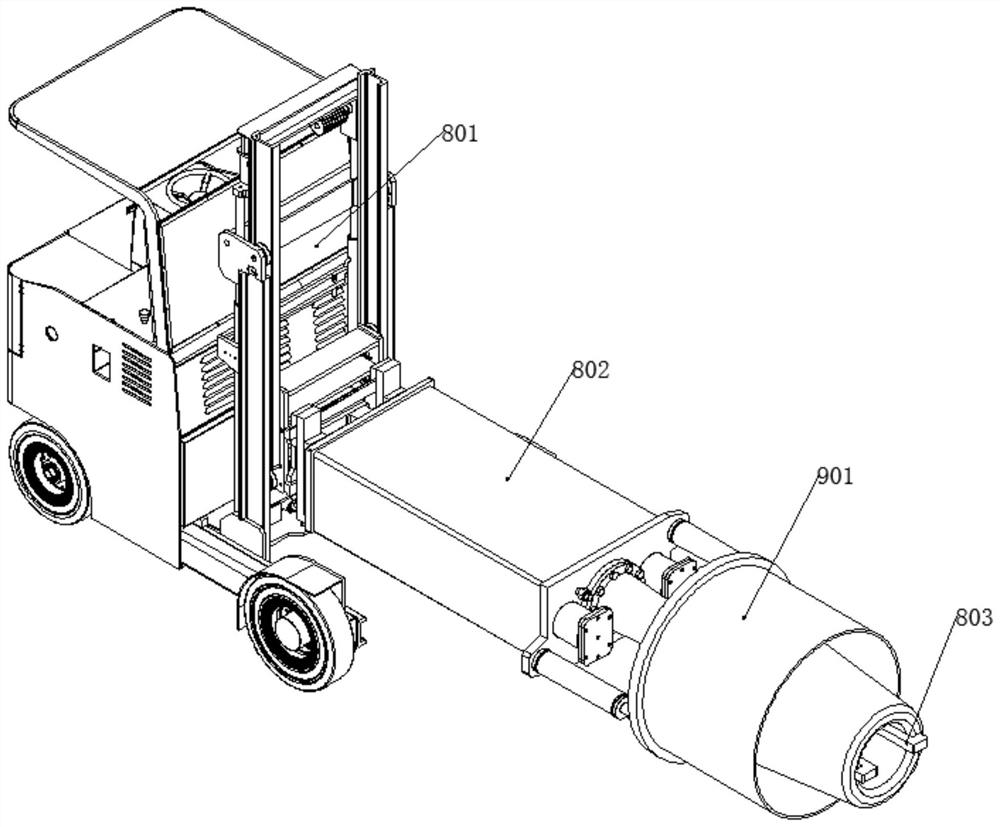

[0063] First, the technical concept of the technical solution disclosed in the present invention will be described. In steel mills, blast furnaces often need to be replaced and repaired, such as the direct blow pipe of the air supply branch pipe, the corrugated pipe of the air supply branch pipe, the small tuyere sleeve, and the tuyere middle sleeve. At present, there are some blast furnace air jacket disassembly and assembly equipment, but these devices often have a single function, and can only disassemble a certain blast furnace air jacket component, and cannot realize the straight blowing pipe of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com