Cement leveling vehicle for road construction

A technology of road construction and cement, which is applied in the field of cement leveling vehicles for road construction, and can solve problems such as poor blood circulation, back pain, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

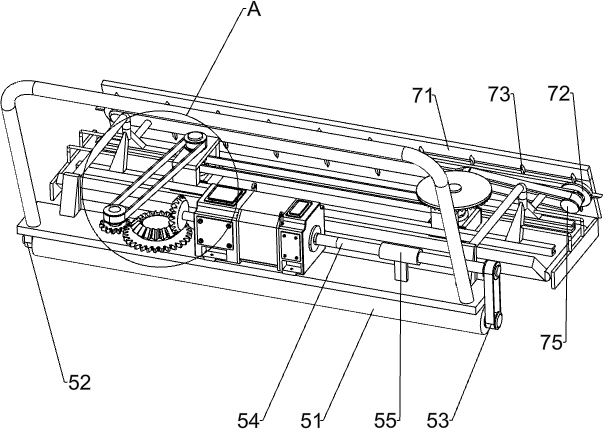

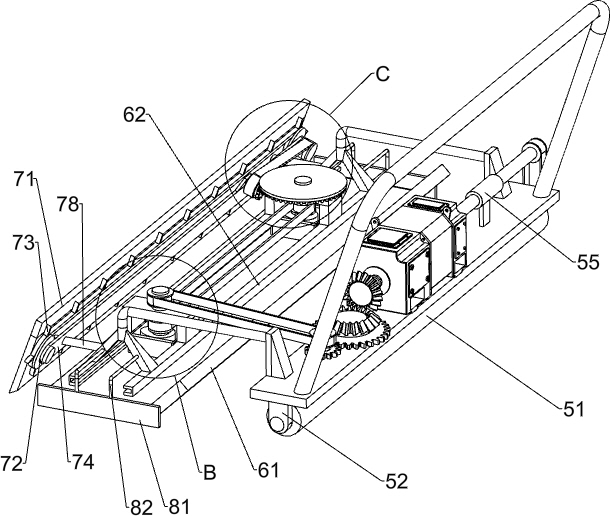

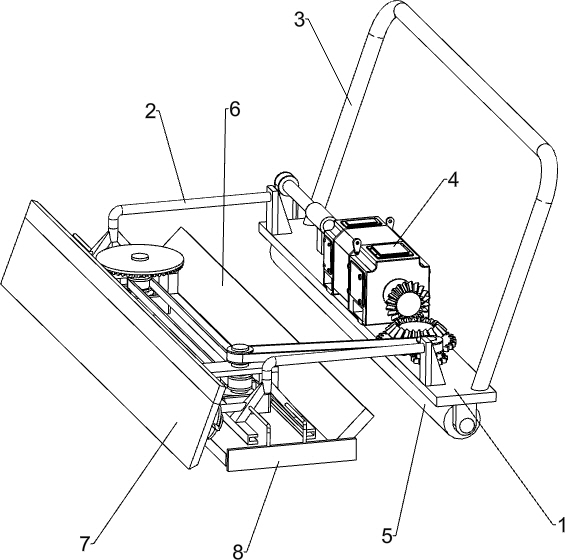

[0024] A cement leveling vehicle for road construction, such as Figure 1-5 As shown, it includes a base plate 1, a connecting frame 2, a handle rod 3, a two-axis servo motor 4, a flattening mechanism 5 and a leveling mechanism 6. The top right side of the base plate 1 is connected with a handle rod 3, and the base plate on the left side of the handle rod 3 1. There are two connecting frames 2 connected to the top, and the two connecting frames 2 are symmetrical front and back. A biaxial servo motor 4 is installed on the top of the bottom plate 1 between the two connecting frames 2. A flattening mechanism 5 is installed on the bottom of the bottom plate 1. The mechanism 5 is connected to the biaxial servo motor 4 through transmission, and a leveling mechanism 6 is installed between the two connecting frames 2, and the leveling mechanism 6 is connected to the flattening mechanism 5 through transmission.

[0025] The flattening mechanism 5 includes a polygonal pressure barrel 51...

Embodiment 2

[0029] On the basis of Example 1, such as Figure 1-3 and Figure 6 Shown, also comprise scraping mechanism 7, and scraping mechanism 7 comprises scraper 71, the 4th drive belt set 72, mud removal block 73, fixed plate 74, the 5th drive belt set 75, cylindrical gear 76, crown gear 77 and the first connecting rod 78, the left side of the connecting frame 2 is connected with the first connecting rod 78, the scraper 71 is connected between the left ends of the two first connecting rods 78, between the outer walls of the two first connecting rods 78 A fixed plate 74 is connected between them, the right side of the fixed plate 74 is connected with a fourth drive belt set 72, and a plurality of mud removal blocks 73 are evenly spaced on the belt of the fourth drive belt set 72. A cylindrical gear 76 is rotatably connected to the fixed plate 74, a fifth transmission belt set 75 is connected between the transmission shaft of the cylindrical gear 76 and the rear transmission shaft of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com