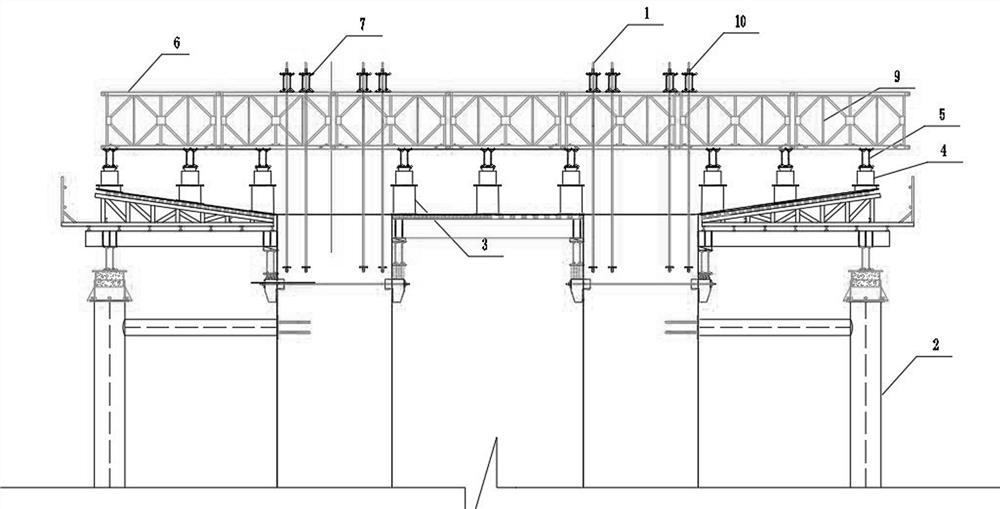

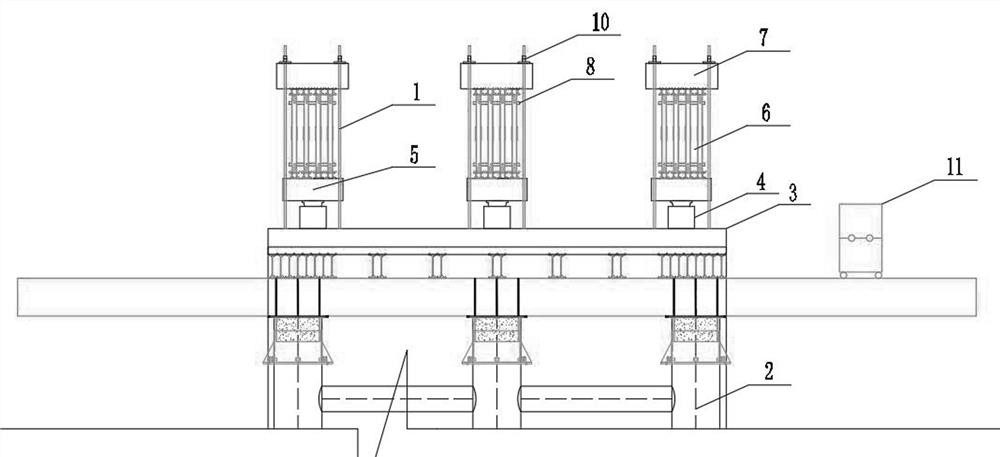

Counter-force pre-pressing system and pre-pressing method for ultrahigh cantilever beam 0 # block support

A cantilever beam, super-high technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of uneven actual load distribution, long unloading time, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] As shown in the figure, a reaction force preloading system for super-high cantilevered beam 0# block support includes steel pipe support 2 erected on the caps on both sides of the pier column. A crossbeam is set up between them to enhance the stability of their connection. A bottom formwork is provided on the top of the steel pipe support 2 and the pier column. The upper end of the bottom formwork is provided with a plurality of distribution beams 3 uniformly arranged along the transverse length of the bridge. Each distribution beam 3 are provided with three groups of jacks 4 evenly arranged along the length direction of the bridge, and the top of each group of jacks 4 is provided with a Bailey truss arranged along the transverse length of the bridge. There are three Bailey trusses, each including Multiple groups of Bailey sheet assemblies, each group of Bailey sheet assemblies includes four Bailey sheets 6, and the four Bailey sheets 6 are fixedly connected by angle ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com