A mining method of downward cementing and filling without top pillar in combined section and stope

A technology of cemented filling and mining methods, which is applied to filling materials, mining equipment, earth-moving drilling, etc., can solve the problems of unguaranteed operation safety, low use frequency of filling pipelines, and reduction of the amount of construction work of the patio, and achieves construction efficiency. High, improve the mining efficiency, reduce the effect of the number of patios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

[0028] A mining method of downward cemented filling without top pillars in combined sections and stopes:

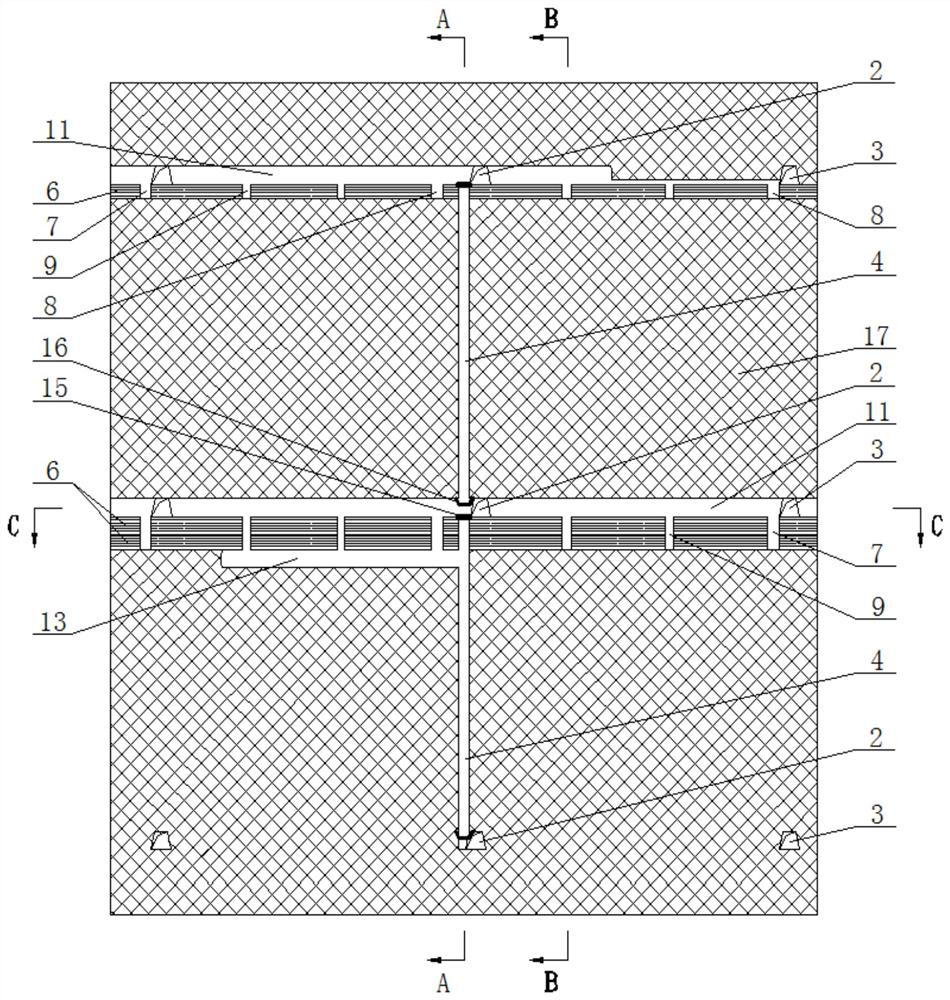

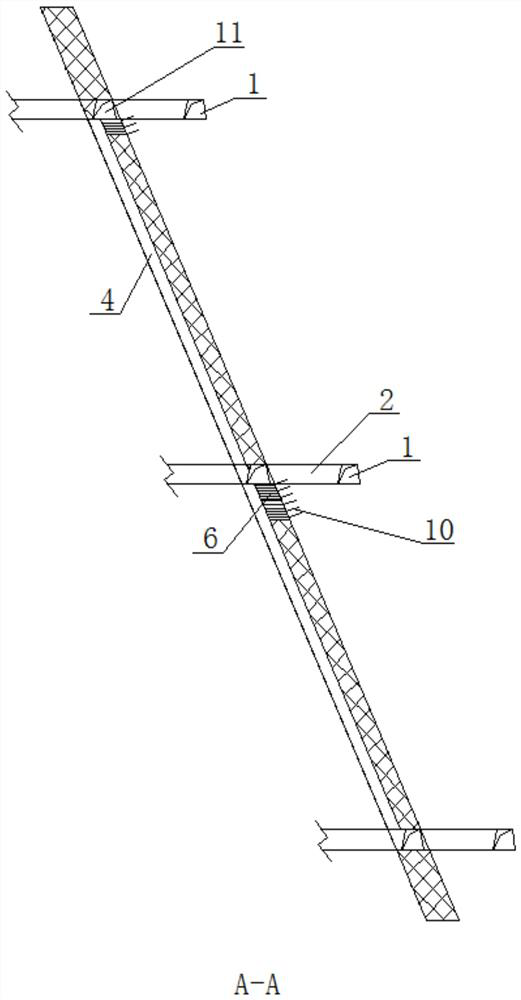

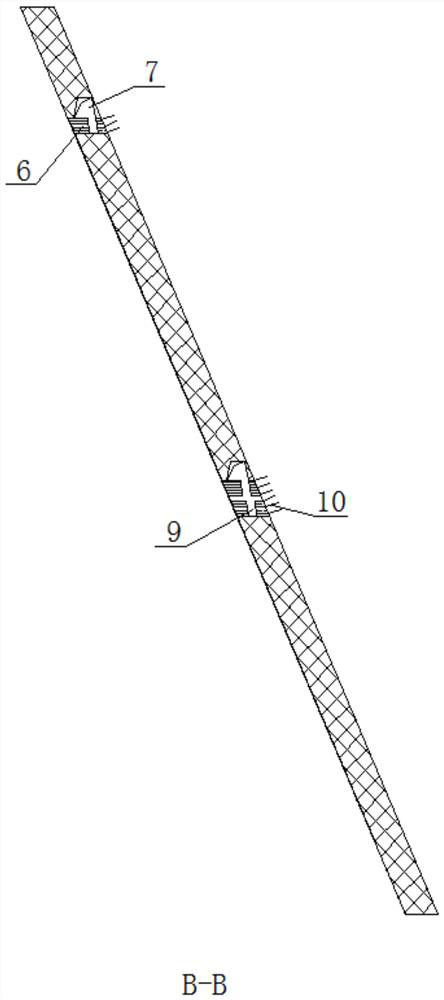

[0029] The arrangement of the stope is as follows: the stope is arranged along the trend of the vein 17 and the inclination angle of the vein 17, and the width of the stope is determined according to the width of the vein 17; along the vertical height of the vein 17, the stope is divided into two middle sections, and each middle section includes the main roadway outside the vein 1. Transportation piercing roadway 2, piercing roadway 3, intra-vein measure roadway 11, and mining roadway 13; the vertical height difference of each middle section is 40m, and each middle section controls the ore vein through the piercing roadway 3; before the mining and cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com