Novel ball valve

A ball valve, a new type of technology, applied in valve details, valve device, valve operation/release device, etc., can solve problems such as inability to realize throttling and control flow, reduce the reliability of ball valve operation, and affect production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

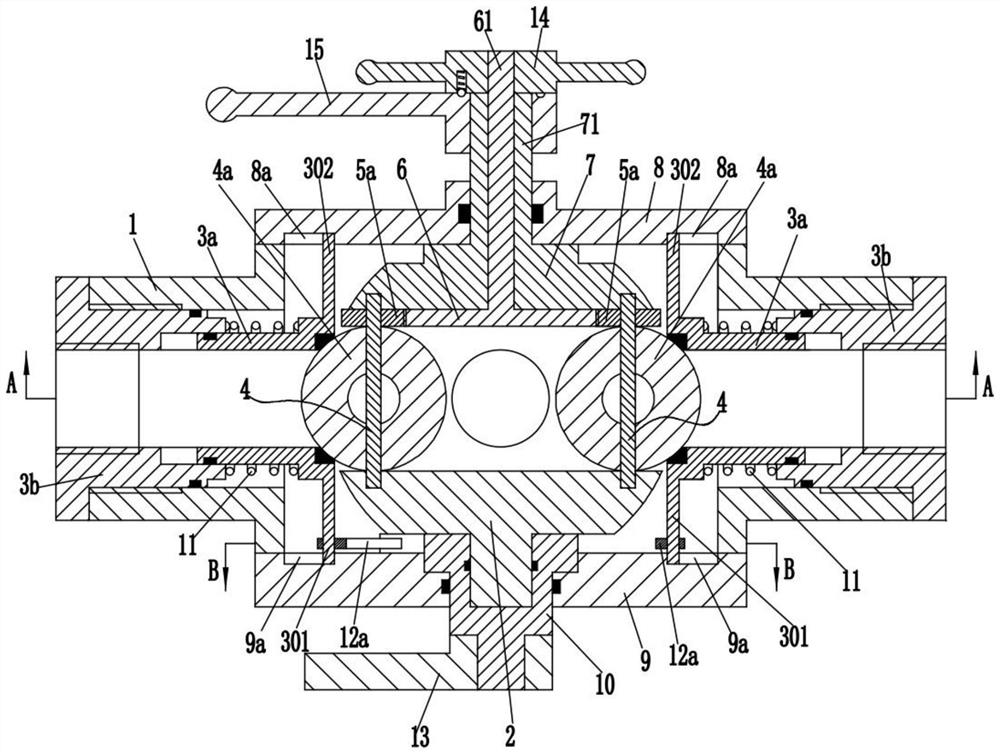

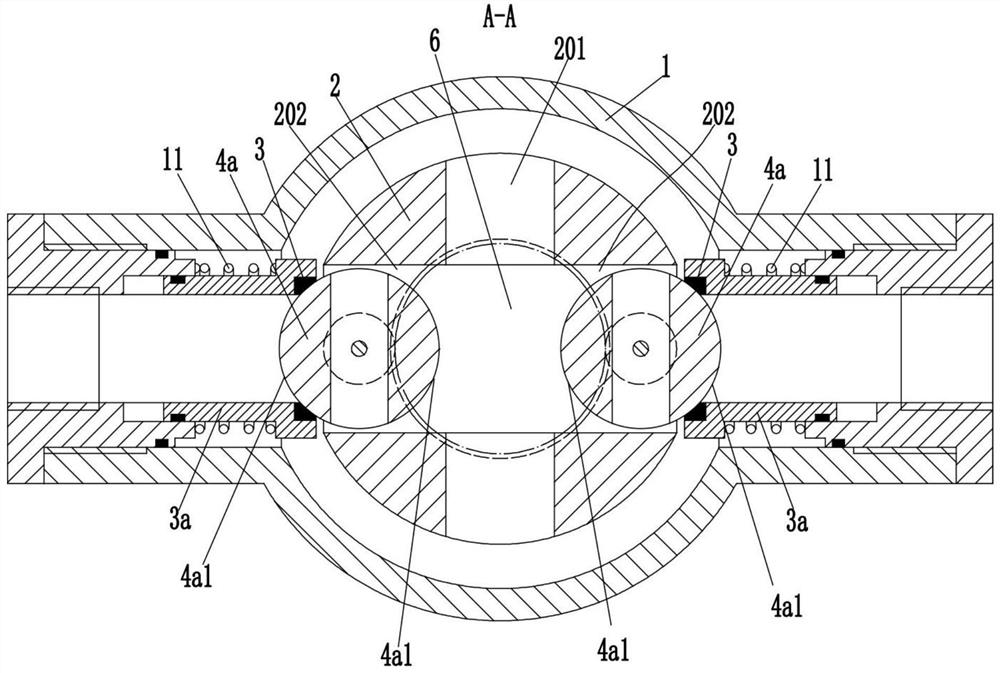

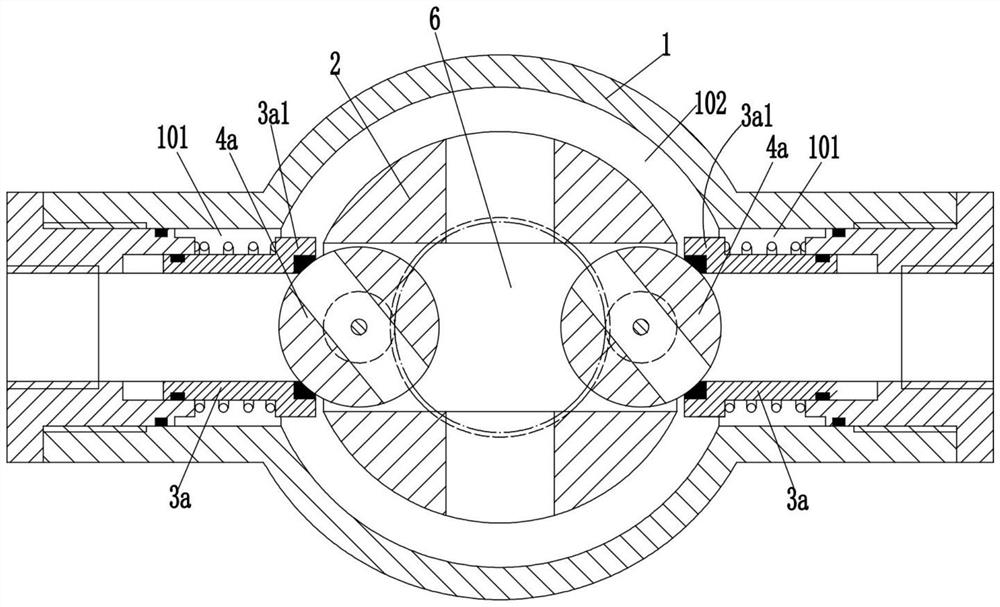

[0030] see Figure 1-10 As shown, a new type of ball valve includes a valve body 1, the valve body 1 is provided with a left and right passage 101, and the valve body 1 is provided with a mounting hole 102 along a direction perpendicular to the passage 101. The valve body 1 An upper end cover 8 is installed on the upper end of the mounting hole 102, and a lower end cover 9 is installed on the lower end of the mounting hole 102; the lower end cover 9 is connected to the lower rotating shaft 10 along the axial direction of the mounting hole 102, and the lower end of the lower rotating shaft 10 The second handle rod 13 is fixedly installed; the upper end of the lower shaft 10 in the mounting hole 102 is rotatably connected to the lower valve ball 2, and the lower valve ball 2 is provided with a flow hole 201; the upper end cover 8 is rotatably connected to a The lower end extends into the sleeve rod 71 in the installation hole 102 , and the lower end of the sleeve rod 71 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com