Heat exchanger for internal thread copper pipe and air conditioner

A technology for heat exchangers and threaded copper tubes is applied in the field of heat exchangers, which can solve the problem of insufficient use efficiency of heat exchangers, and achieve the effects of accelerating heat exchange efficiency, poor heat dissipation, and improving heat exchange rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

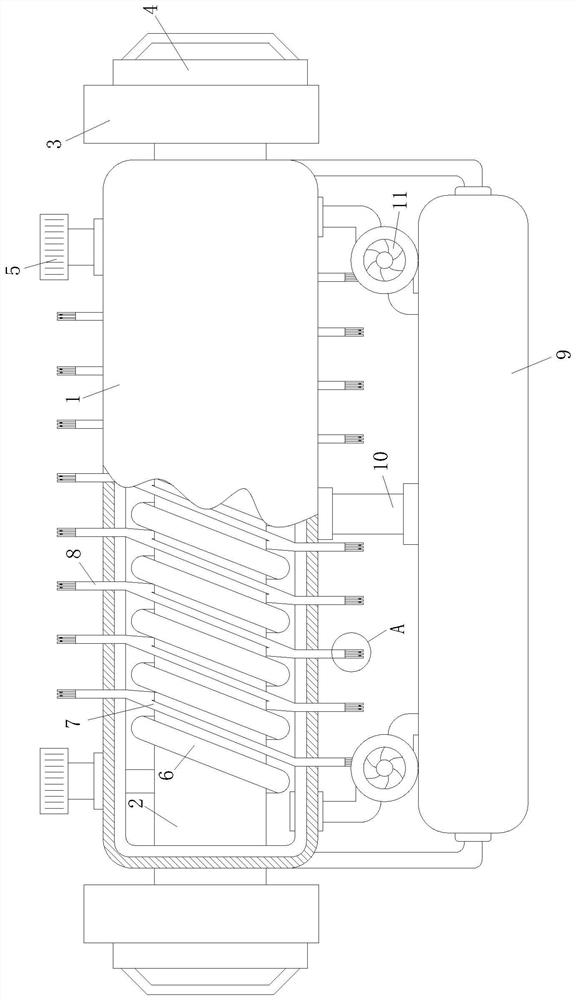

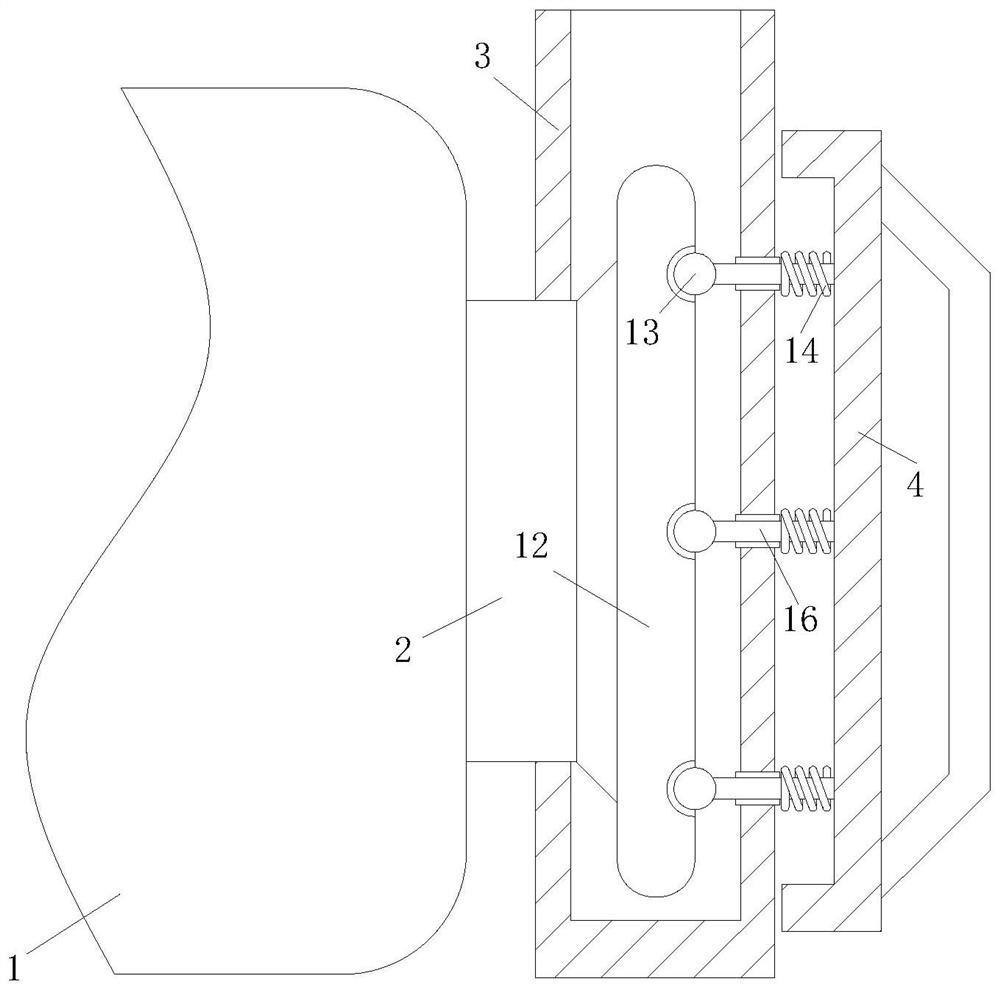

[0028] As an embodiment of the present invention, the threaded copper tube 6 and the separator 7 are wound and connected, and there is a gap between the threaded copper tube 6 and the separator 7, and the center of the bottom of the heat exchange cylinder 1 passes through The connecting pipe 10 communicates with the interior of the water tank 9; by adopting the above-mentioned technical scheme, the threaded copper pipe 6 and the partition 7 are wound and connected, and there is a gap between the threaded copper pipe 6 and the partition 7, and the gap allows water to flow inside it. Carry out the function of circulation, and then take away the heat, and the bottom center of the heat exchange cylinder 1 communicates with the inside of the water tank 9 through the connecting pipe 10, and the water that takes away the heat flows into the water tank 9 through the connecting pipe 10 for storage, so that the heat exchange The water that realizes the superheat exchange in the cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com