Mechanical loading type packer rubber sleeve simulation loading sealing experiment device and method

A technology of mechanical loading and experimental equipment, which is applied in the direction of measuring equipment, testing of mechanical components, testing of fluid tightness, etc., and can solve problems such as only measuring contact pressure and inaccurate applied load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

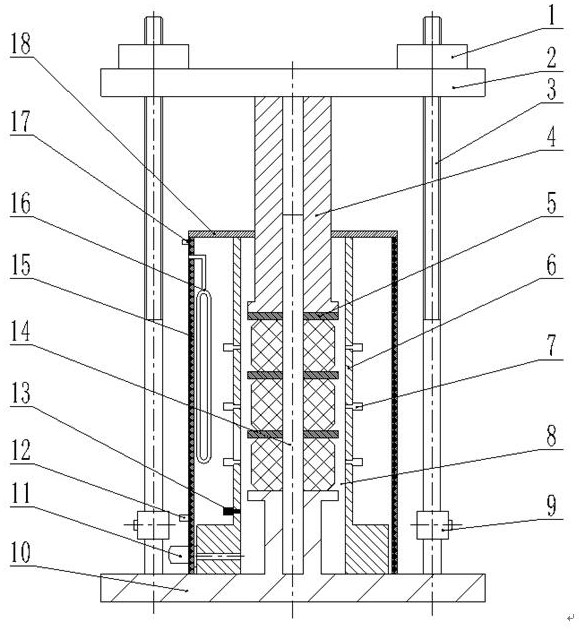

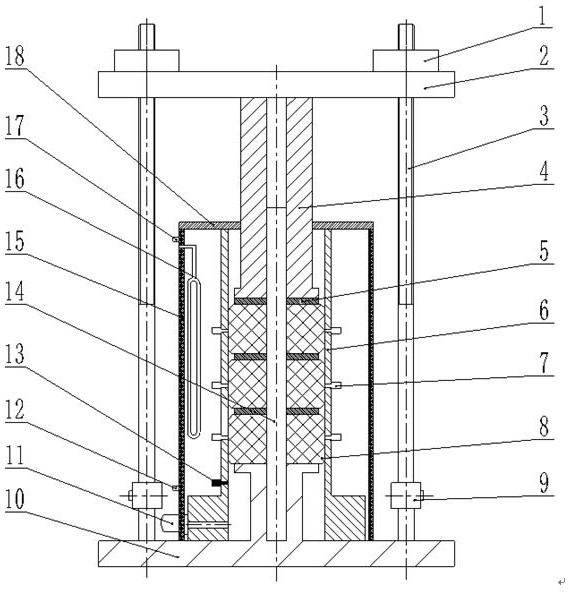

[0046] figure 1 The shown packer test device can measure the contact stress distribution of the rubber sleeve 8 under different loads. When measuring the contact stress of the rubber sleeve 8, first place the rubber sleeve 8 and the spacer ring 5 on the support element 14 in sequence, and then Install the central tube 4 to press the rubber tube 8 tightly, and then install the loading beam 2 and the nut 1. After the tool is installed in place, adjust the performance of the strain sensor 7 and the pressure sensor 13. After confirming that the performance of the sensor is correct, install the strain sensor 7 and the pressure sensor. The reading on the digital display screen of 13 is zero, start to use the wrench to turn the nut 1 to move down, the torque and axial load are transmitted to the loading beam 2, due to the action of the loading beam 2, the upper torque is eliminated, it is designed in this way, so that the center The tube 4 is pressed against the spacer ring 5 only by...

Embodiment 2

[0048] When it is necessary to measure the sealing performance of the rubber cartridge 8, the preset pressure gas can be injected from the high-pressure fluid injection head 11, and the injection is stopped when the pressure in the cavity reaches the requirement. At this time, the change rule of the pressure sensor value with time is recorded. The sealing performance of the rubber cartridge 8 can be judged according to the change of the pressure value.

Embodiment 3

[0050] To test the influence of temperature on rubber core deformation and sealing performance, through the water injection valve 16 installed on the heat preservation shell 14, an appropriate amount of water can be injected into the heat preservation shell 14, and then the electric heating device 15 heats the water, and the electric heating device 15 Automatic control can be performed to maintain the water temperature at a constant temperature. After the test is finished, water can be discharged from the water outlet valve 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com