A kind of mxene/graphene composite nanosheet and its preparation method and application, electrode pole piece and its application

A graphene nanosheet and graphene composite technology, applied in the field of two-dimensional materials, can solve the problems of poor lithium storage performance, lithium storage performance hindrance, microscopic heterogeneous structure unfavorable lithium storage performance of materials, etc., and achieve excellent lithium storage performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

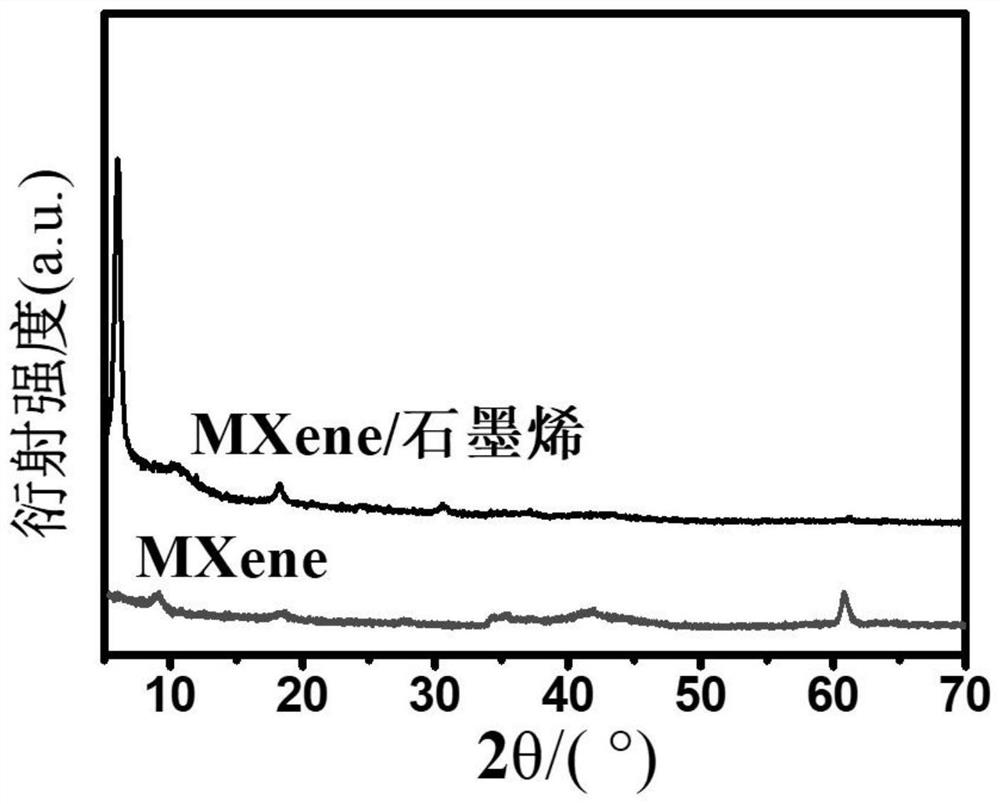

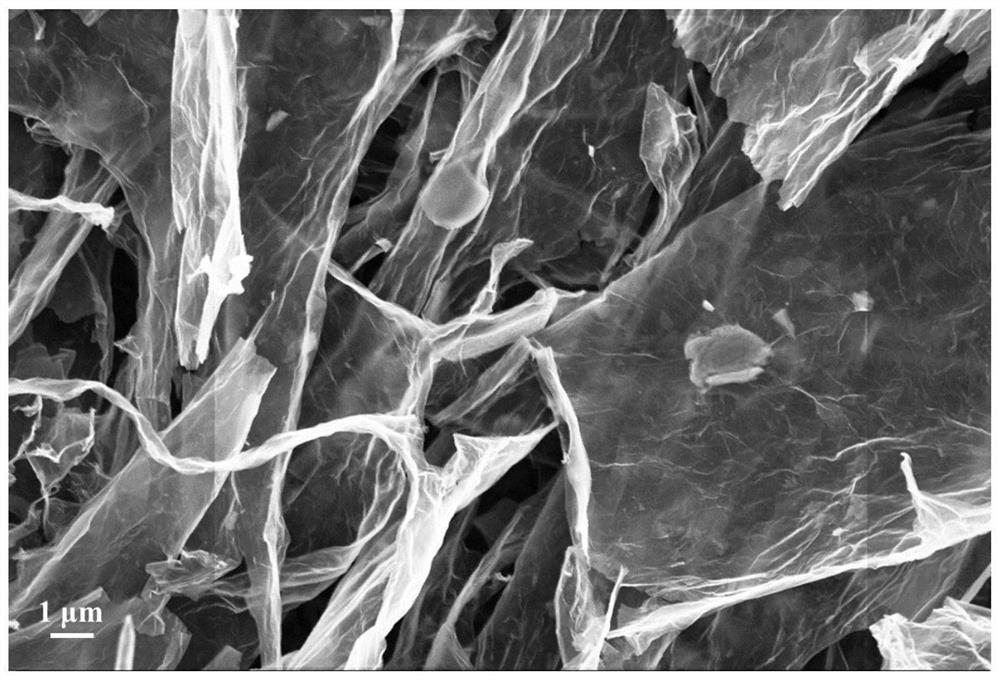

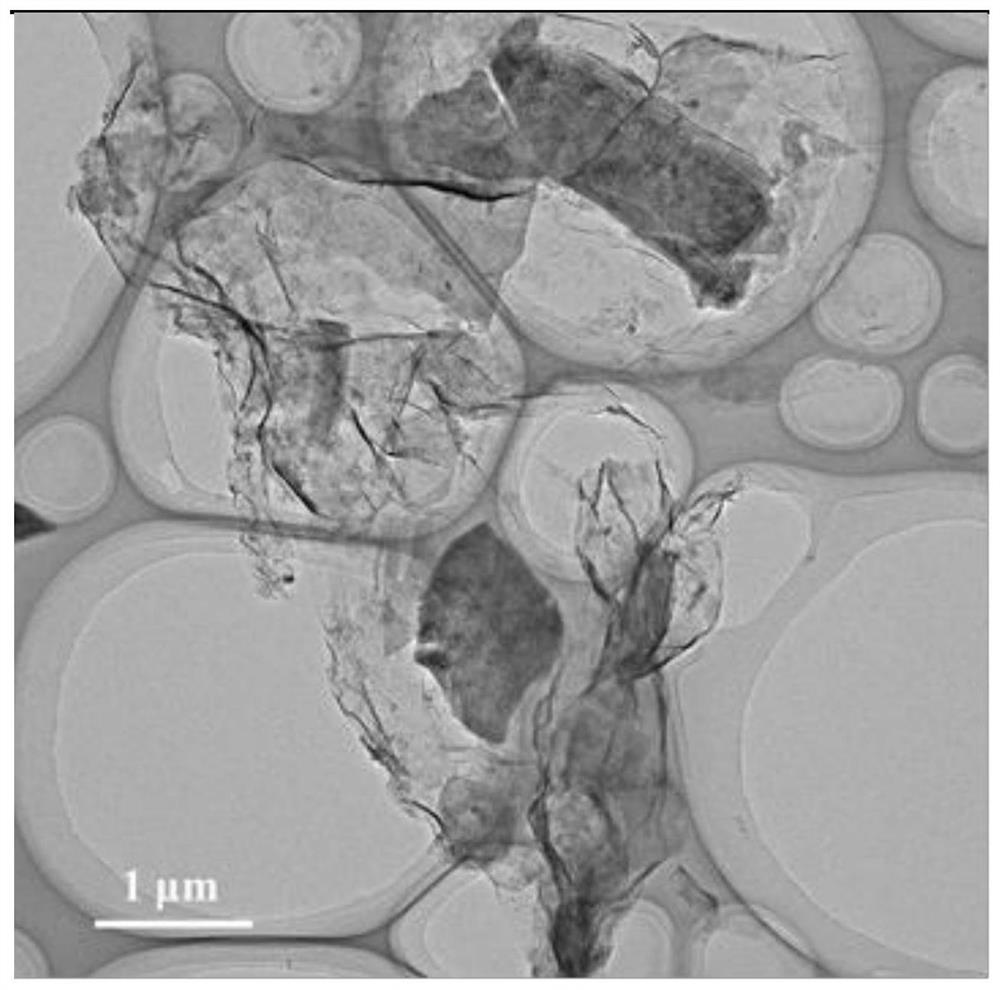

[0028] The invention provides a kind of preparation method of MXene / graphene composite nanoplate, comprises the following steps:

[0029] Mix MAX and hydrofluoric acid solution for etching to obtain MXene;

[0030] The MXene and the tetrabutylammonium hydroxide solution are mixed, and ultrasonic treatment is carried out after electrostatic adsorption to obtain a dispersion liquid of stripping MXene nanosheets;

[0031] The stripped MXene nanosheet dispersion is mixed with the graphene oxide suspension to carry out a self-assembly reaction to obtain MXene nanosheets / graphene oxide nanosheets;

[0032] Under a protective atmosphere, the MXene nanosheets / graphene oxide nanosheets are subjected to a reduction reaction to obtain MXene / graphene composite nanosheets.

[0033] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0034] The invention mixes MAX and hydrofluoric a...

Embodiment 1

[0069] (1) Put 3g of MAX powder in 60mL of 40wt% hydrofluoric acid solution to etch for 24h under stirring conditions, centrifuge, wash the obtained solid components with deionized water, and freeze-dry them at -45°C for 24h to obtain MXene;

[0070] (2) 2g of the MXene was placed in 70mL 25wt% TBAOH solution, electrostatically adsorbed at room temperature and stirred for 18h, centrifuged, and the resulting solid component was washed with deionized water and freeze-dried at -45°C for 24h, To obtain the exfoliated MXene nanosheets; place 0.1g of the exfoliated MXene nanosheets in 100mL of deionized water, and sonicate for 120min under a protective atmosphere to obtain an exfoliated MXene nanosheet dispersion with a concentration of 1g / L;

[0071] (3) Mix the 1g / L exfoliated MXene nanosheet dispersion and 20g / L graphene oxide suspension (the mass ratio of exfoliated MXene nanosheets and graphene oxide is 1:1) at room temperature and under stirring conditions , self-assembly rea...

Embodiment 2

[0078] Prepare MXene / graphene composite nanosheet according to the method for embodiment 1, and the difference with embodiment 1 is, the concentration of stripping MXene nanosheet dispersion liquid is 2g / L in step (2); Stripping MXene nanosheet in step (3) The mass ratio to graphene oxide is 1:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com