Nanometer nickel cobalt oxide and preparation method thereof

A nano-cobalt, nickel acid technology, applied in the direction of active material electrodes, structural parts, electrical components, etc., to achieve the effect of reducing cost and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

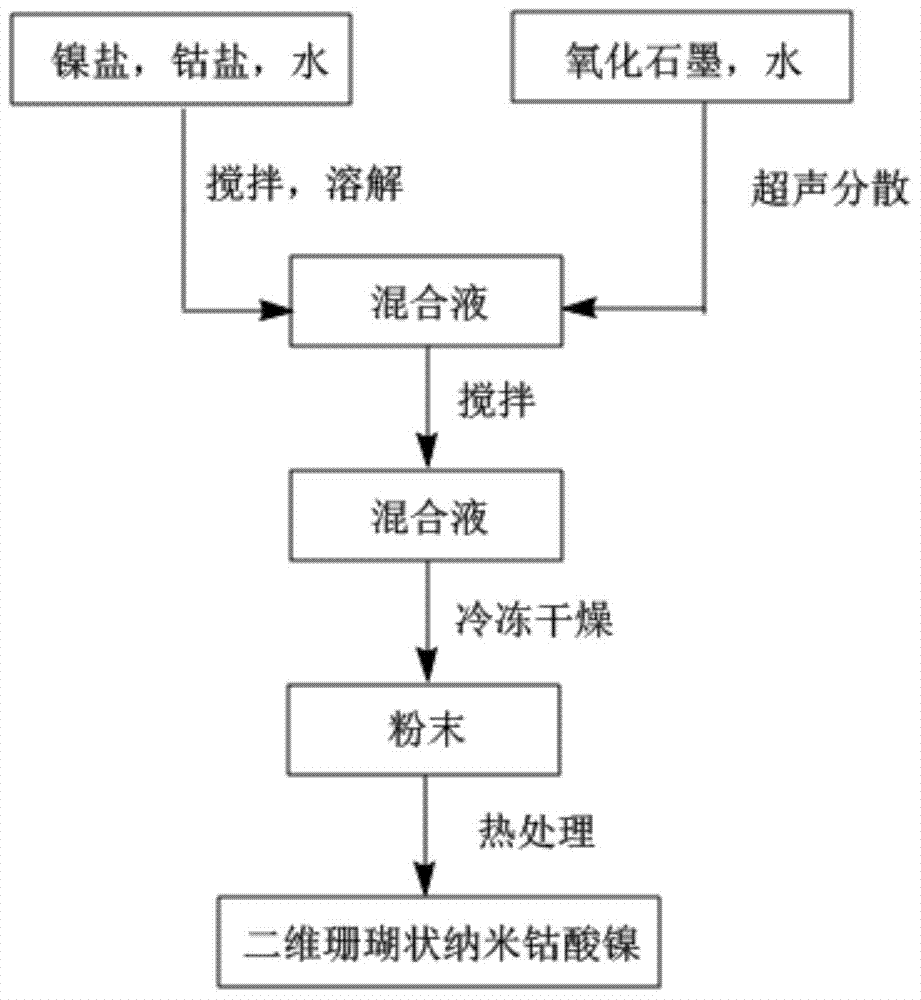

[0027] The first step: ultrasonically disperse 60 mg of graphite oxide in deionized water for 120 minutes to obtain a graphene oxide solution;

[0028] In the second step, 0.291g of nickel nitrate and 0.582g of cobalt nitrate were dissolved in 30mL of water and stirred for 60 minutes;

[0029] In the third step, the systems obtained in the first two steps were mixed and stirred for 60 minutes;

[0030] In the fourth step, the reaction system of the third step is freeze-dried;

[0031] In the fifth step, the powder obtained after freeze-drying in the fourth step is heat-treated at 400° C. for 1 hour under a nitrogen atmosphere to prepare a two-dimensional coral-like nano-nickel cobaltate.

Embodiment 2

[0033] The first step: ultrasonically disperse 20 mg of graphite oxide in deionized water for 30 minutes to obtain a graphene oxide solution;

[0034] In the second step, 0.291g of nickel nitrate and 0.582g of cobalt nitrate were dissolved in 30mL of water and stirred for 20 minutes;

[0035] In the third step, the systems obtained in the first two steps were mixed and stirred for 30 minutes;

[0036] In the fourth step, the reaction system of the third step is freeze-dried;

[0037] In the fifth step, the powder obtained after freeze-drying in the fourth step is heat-treated at 200° C. for 5 hours under a nitrogen atmosphere to prepare a two-dimensional coral-shaped nano-nickel cobaltate.

Embodiment 3

[0039] The first step: ultrasonically disperse 30 mg of graphite oxide in deionized water for 60 minutes to obtain a graphene oxide solution;

[0040] In the second step, 0.291g of nickel nitrate and 0.582g of cobalt nitrate were dissolved in 30mL of water and stirred for 30 minutes;

[0041] In the third step, the systems obtained in the first two steps were mixed and stirred for 60 minutes;

[0042] In the fourth step, the reaction system of the third step is freeze-dried;

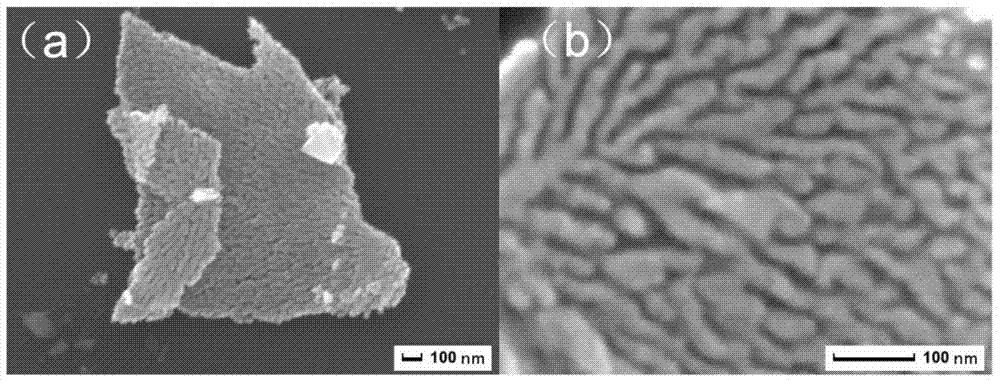

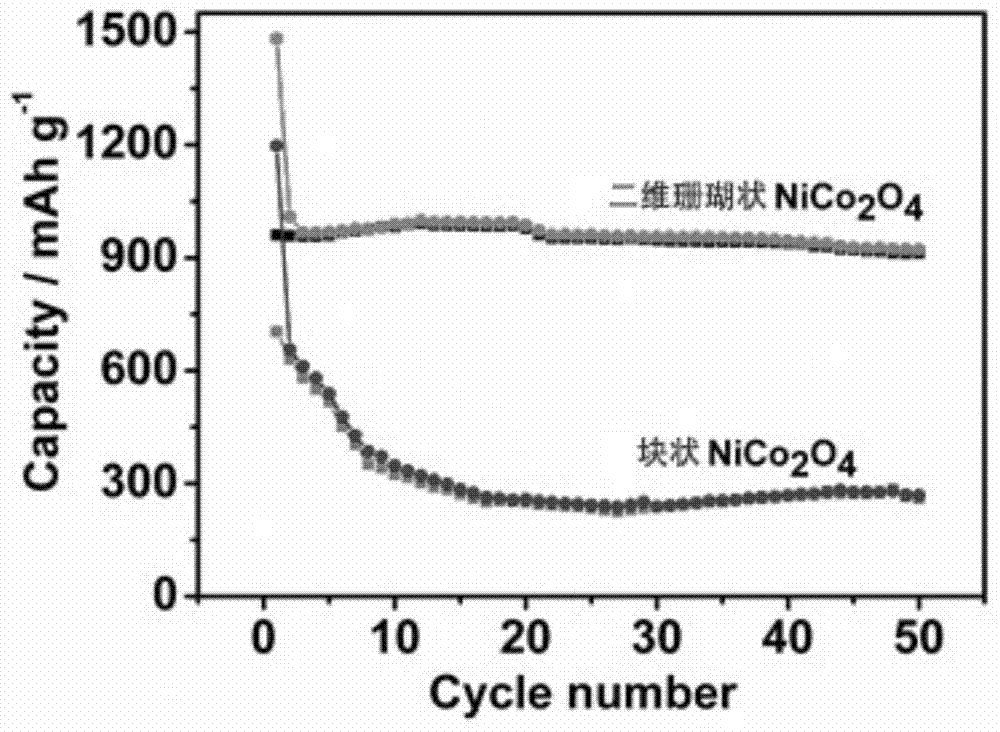

[0043] In the fifth step, the powder obtained after freeze-drying in the fourth step is heat-treated at 300° C. for 2 hours under a nitrogen atmosphere to obtain a two-dimensional coral-like nano-nickel cobaltate. The field emission scanning electron microscope shows figure 2 shown. The prepared two-dimensional coral-like nano-nickel cobalt oxide was used as the anode material of lithium-ion battery for electrochemical performance test, the results are as follows image 3 As shown, compared with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com