Power acting and power generating all-in-one machine

It is an all-in-one machine and work technology, which is applied in the direction of electrical components, electromechanical devices, etc. It can solve the problems of drop in starting current, increase in torque, and high noise, and achieve the effect of increased torque, reduced use cost, and low noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

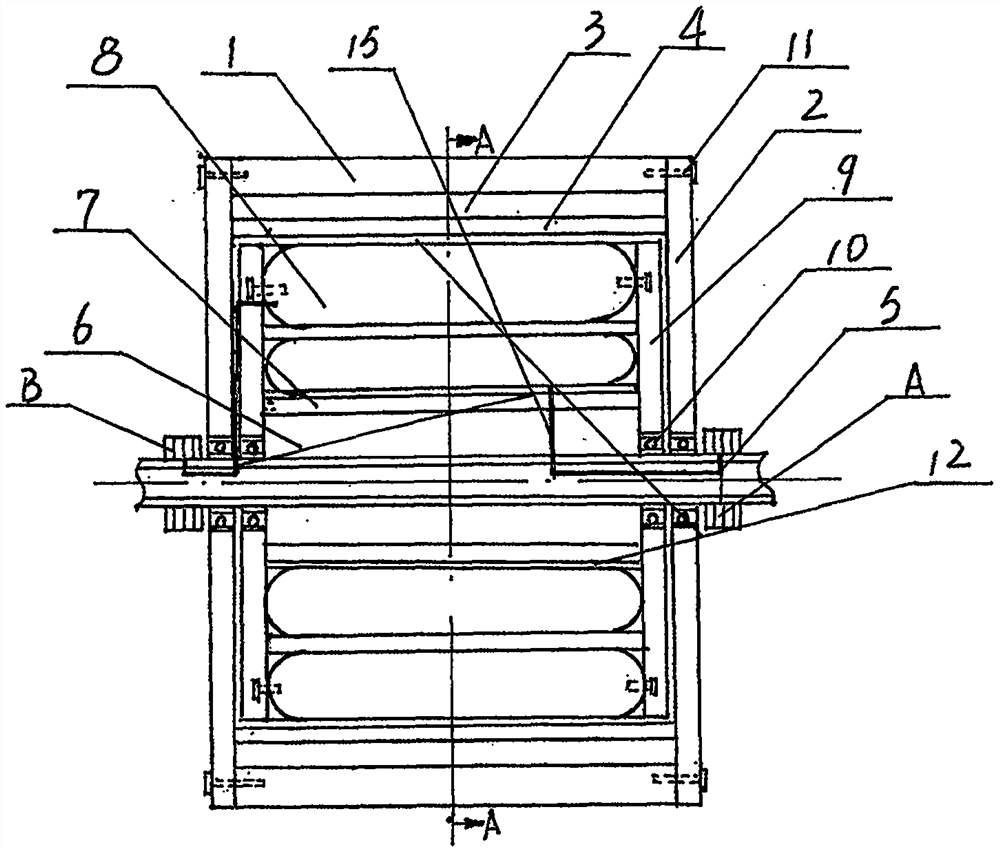

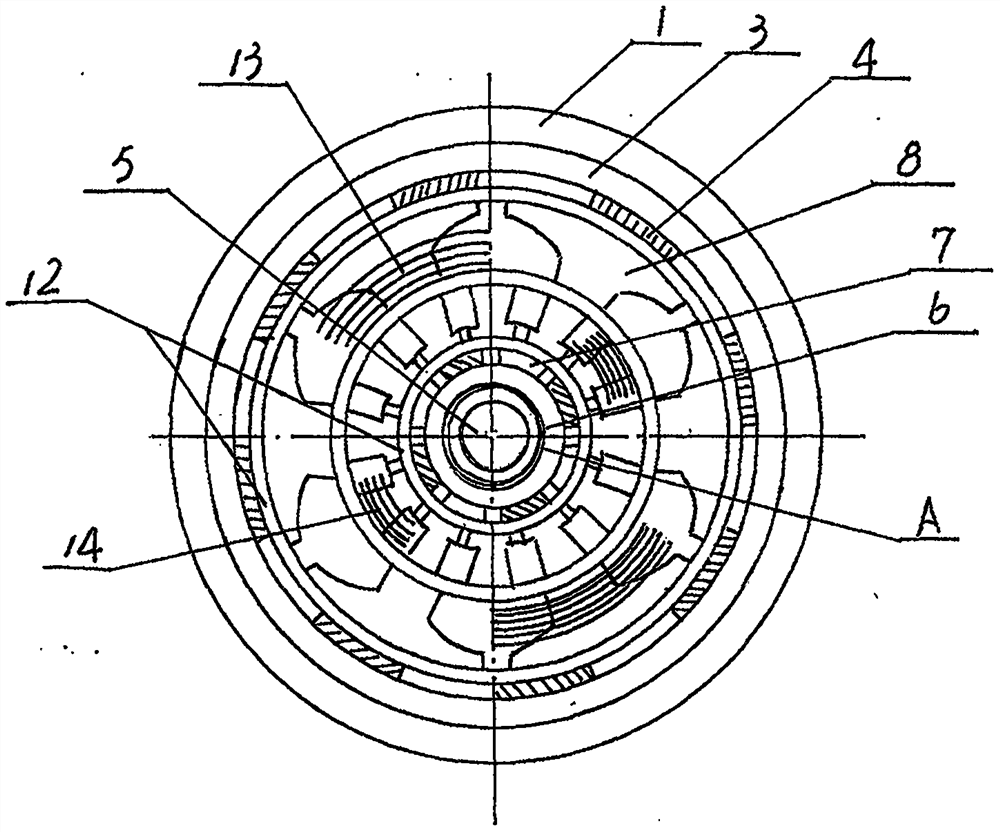

[0008] Embodiment 1: as figure 1 , figure 2 As shown, the two outer end covers 2 of a kind of dynamic work and power generation integrated machine are fixed on both ends of the walking outer wheel shell 1 with bolts 11, and are placed on the hollow shaft 5 with bearings 10, and the fixed strong magnetic silicon steel sheet 3 is fixed on the The inner end of the walking outer wheel shell 1, the rectangular strong magnet 4 of the generator, one N pole and one S pole crossed and equidistantly arranged, are embedded in the inner end of the fixed strong magnetic silicon steel sheet 3, the silicon steel sheet 6 is fixed on the hollow shaft 5, and the strong magnetic 7 One piece of N pole and one piece of S pole are arranged crosswise and equidistantly inlaid on the outer periphery of the silicon steel sheet 6 to form the stator of the generator. Wound in the wire slot of the inner ring of the silicon steel sheet 8 to form the motor rotor.

Embodiment 2

[0009] Embodiment 2: as figure 1 , figure 2 As shown, a slip ring A is provided at the right outer end of the hollow shaft 5 of the integrated machine for power work and power generation, and the three wires 15 of the slip ring A are connected to the coil 14 of the working motor through the inner hole of the hollow shaft 5, and the slip ring B is arranged on the At the left outer end of the hollow shaft 5, the three wires 15 of the slip ring B are connected to the coil 13 of the generator winding through the inner hole of the hollow shaft 5 .

Embodiment 3

[0010] Embodiment 3: as figure 1 , figure 2 As shown, the two inner end covers 9 of the integrated machine for power work and power generation are fixed to both ends of the winding silicon steel sheet 8 with bolts 11, and are placed on the hollow shaft 5 with bearings 10 for movement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com