Decorative sheet paper pasting device

A technology for decorative boards and stickers, which is applied to adhesive application devices, wooden veneer joints, wood processing appliances, etc. It can solve problems such as complicated operation process, time-consuming and labor-intensive, and difficulty in ensuring the flatness of stickers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

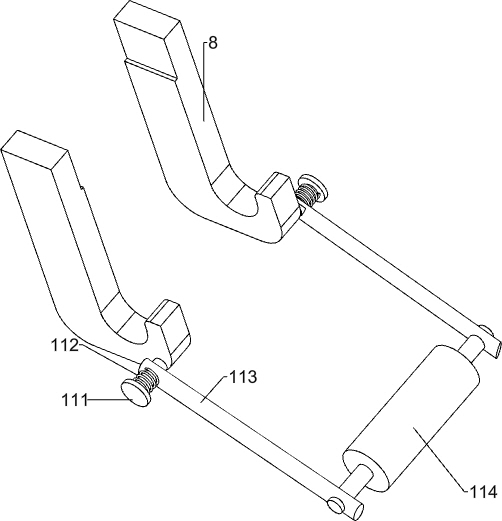

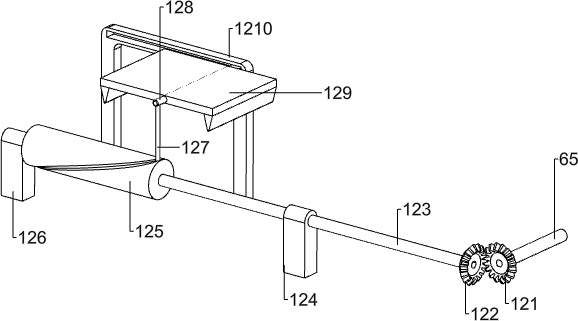

[0044] A decorative panel sticker device such as figure 1 As shown, it includes a base 1, a discharge plate 2, a bracket 3, a discharge frame 4, a glue discharge frame 5, a pushing mechanism 6, a glue brushing mechanism 7, a mounting plate 8 and a first roller 9. The top of the base 1 is connected with a discharge The material plate 2, the front and rear sides of the top of the base 1 are connected with the support 3, the discharge frame 4 is connected between the left part of the support 3, the plastic discharge frame 5 is connected between the right part of the support 3, and the pusher is connected on the left side of the top of the base 1 Mechanism 6, is connected with brushing mechanism 7 between pushing mechanism 6 and glue frame 5, and is connected with mounting plate 8 on the front and rear sides of glue frame 5 right, and first roller 9 is placed between mounting plate 8 bottoms.

[0045] When the staff needs to paste the decorative board, they can first place the dec...

Embodiment 2

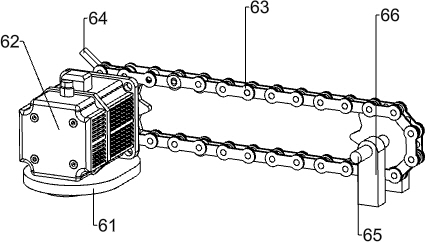

[0047] On the basis of Example 1, such as figure 2 As shown, the pushing mechanism 6 includes a mounting base 61, a motor 62, a chain 63, a push block 64, a first support frame 66 and a first rotating shaft 65, the upper left part of the base 1 is connected with the mounting base 61, and the upper side of the mounting base 61 A motor 62 is connected, three first support frames 66 are connected to the upper left part of the base 1, and a first rotating shaft 65 is rotatably connected between the upper part of the first support frame 66 on the left side and the first support frames 66 on both sides of the right part. , the front end of the first rotating shaft 65 on the left is connected with the output shaft of the motor 62, a chain 63 is connected between the first rotating shaft 65 on both sides, and a push block 64 is connected on the left side of the chain 63 upper side.

[0048] The staff puts the decorative plate into the discharge frame 4, starts the motor 62 to work, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com