Mortar supply method, mortar supply equipment and crystal bar cutting system

A technology of cutting system and supply method, applied in the direction of stone processing equipment, climate sustainability, final product manufacturing, etc., can solve problems such as poor cutting stability, unreasonable mortar supply, and poor wafer warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0043] L 0 =300mm, V 0 =180L, R=70%;

[0044] V 1 =(L-(1-0.7)*300)*180 / (0.7*300)=(L-90)*6 / 7

[0045] V 1 =(L-(1-0.7)*300)*180 / (0.7*300)=(L-90)*6 / 7

[0046] V 2 =(300-L)*180 / ((2-0.7)*300)=(300-L)*6 / 13

[0047] Among them, when inputting different L values, different V can be obtained 1 and V 2 , so that the value of the above-mentioned setting ratio can be adjusted.

example 2

[0049] L 0 =300mm, V 0 =200L, R=60%;

[0050] V 1 =(L-(1-0.6)*300)*200 / (0.6*300)=(L-120)*10 / 9

[0051] V 2 =(300-L)*200 / ((2-0.6)*300)=(300-L)*10 / 21

[0052] Among them, when inputting different L values, different V can be obtained 1 and V 2 , so that the value of the above-mentioned setting ratio can be adjusted.

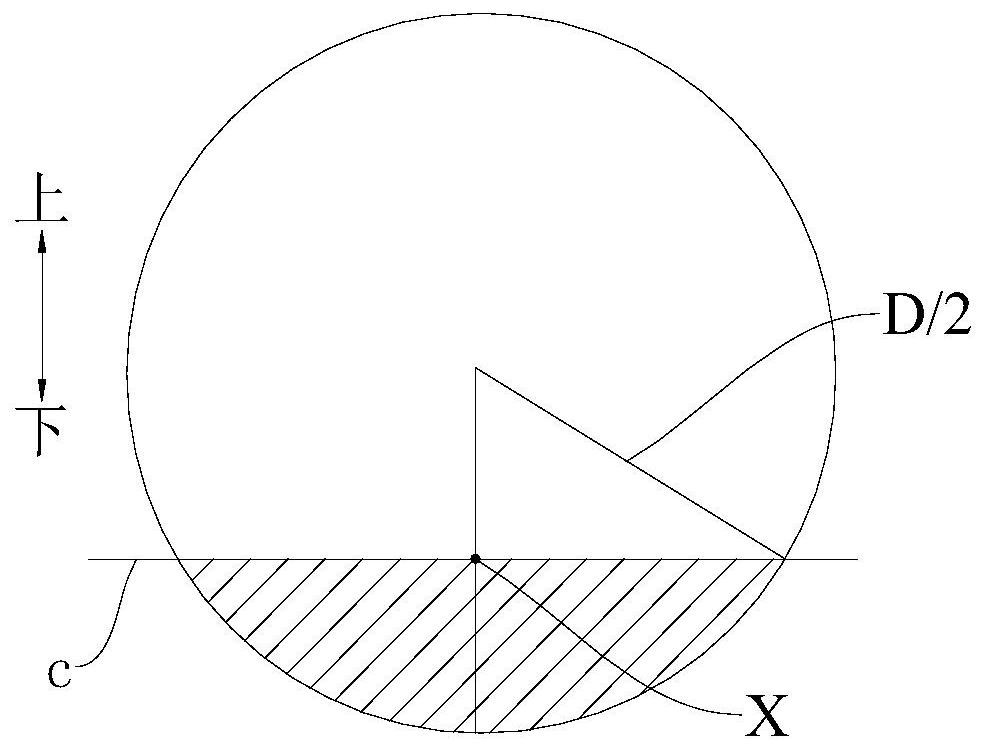

[0053] According to other embodiments of the present invention, refer to figure 2 , adjust the setting ratio in real time according to the cutting area of the ingot. The cross-section of the ingot is usually circular. When cutting the ingot, it is cut from one radial side of the ingot to the other radial side of the ingot. When cutting the ingot at different positions, the cutting area is different. In the process of ingot cutting, the cutting area first increases and then decreases. The cutting area of the ingot is different, and the required cutting efficiency is different. Thus, the setting ratio can be adjusted in real time according to the cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com