Modeling machining method for high-temperature forming male die

A modeling method and punch technology, applied in the field of high temperature forming punch modeling and processing, can solve the problems of high labor intensity, high skill level, low tooling accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below.

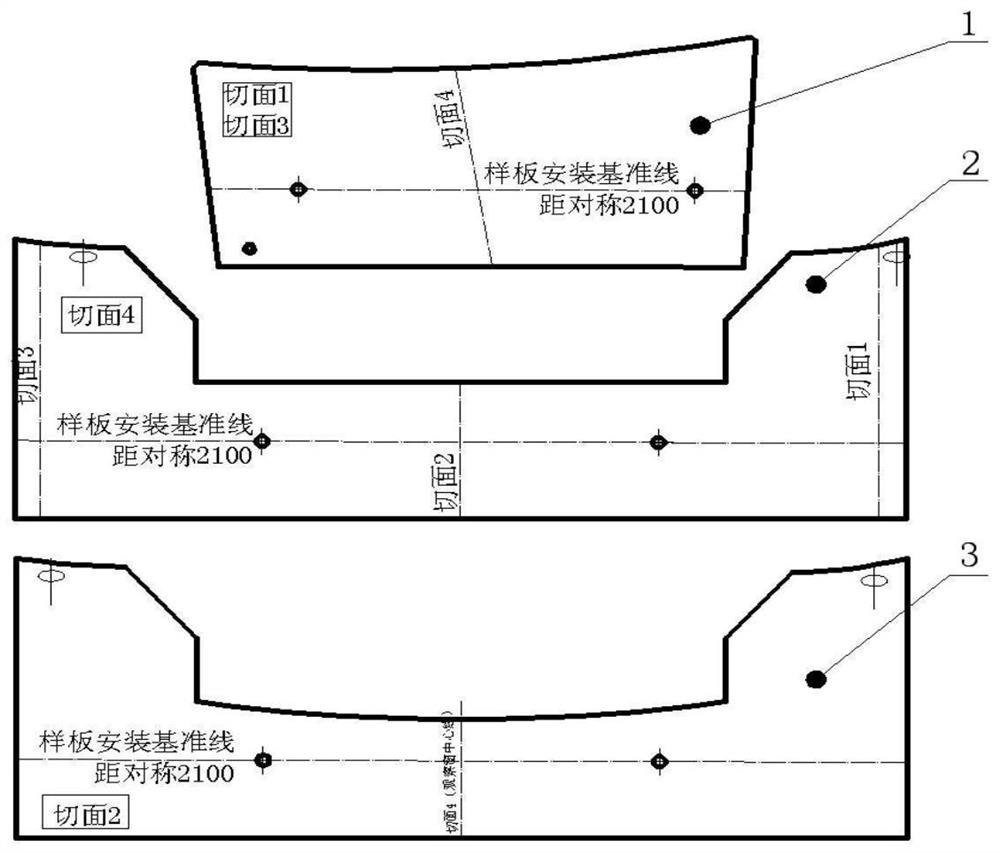

[0035] 1. If figure 1 According to the corresponding drawing number, find out each "two-dimensional section template 1-4" required for this type of tooling; check whether the various reference holes, lines, and marks on the section template are complete.

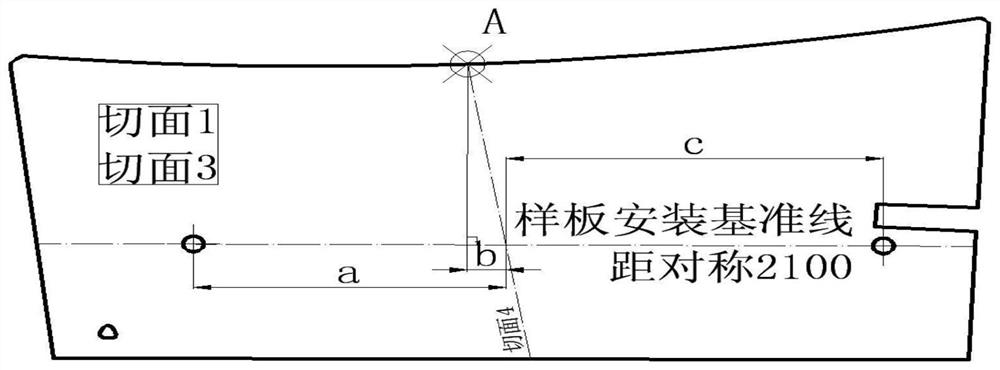

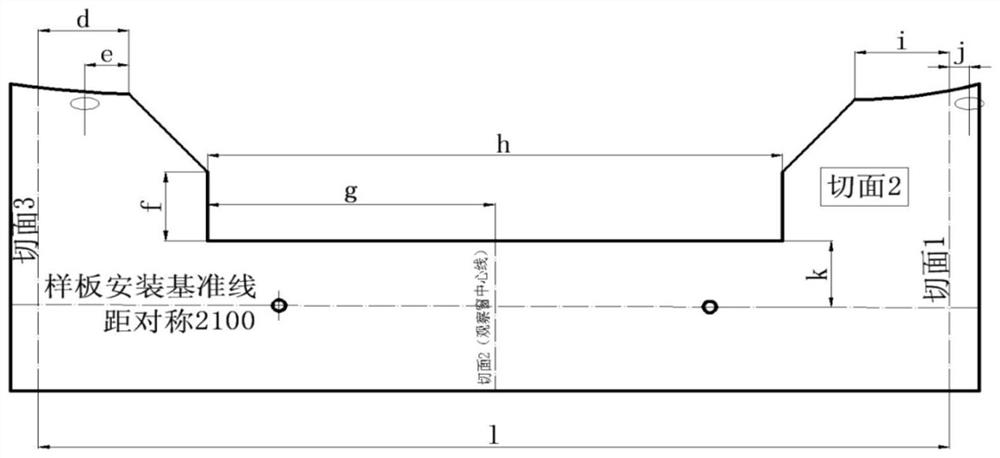

[0036] 2. If Figure 2-4 , use conventional measuring tools such as calipers, ground gauges, steel rulers, etc., to measure the key positioning dimensions a~q on the "two-dimensional section template 1~4". And in the 3D modeling software, establish the spatial relationship model corresponding to the "2D section template", that is, make Figure 2-4 Each of the "section template 1 ~ section template 4" digital model.

[0037] 3. If Figure 5 , through the mutual superposition of "2D section templates", "size 62" is the arc difference between "2D section section template 1" and "2D section section template 2"; "size 26" is "2D section section template...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com