Cladding layer cross section contour curve under broadband laser effect and modeling method

A technology of cross-sectional profile and modeling method, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of increasing production costs and labor costs, and achieve savings in test costs, production costs, and operability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

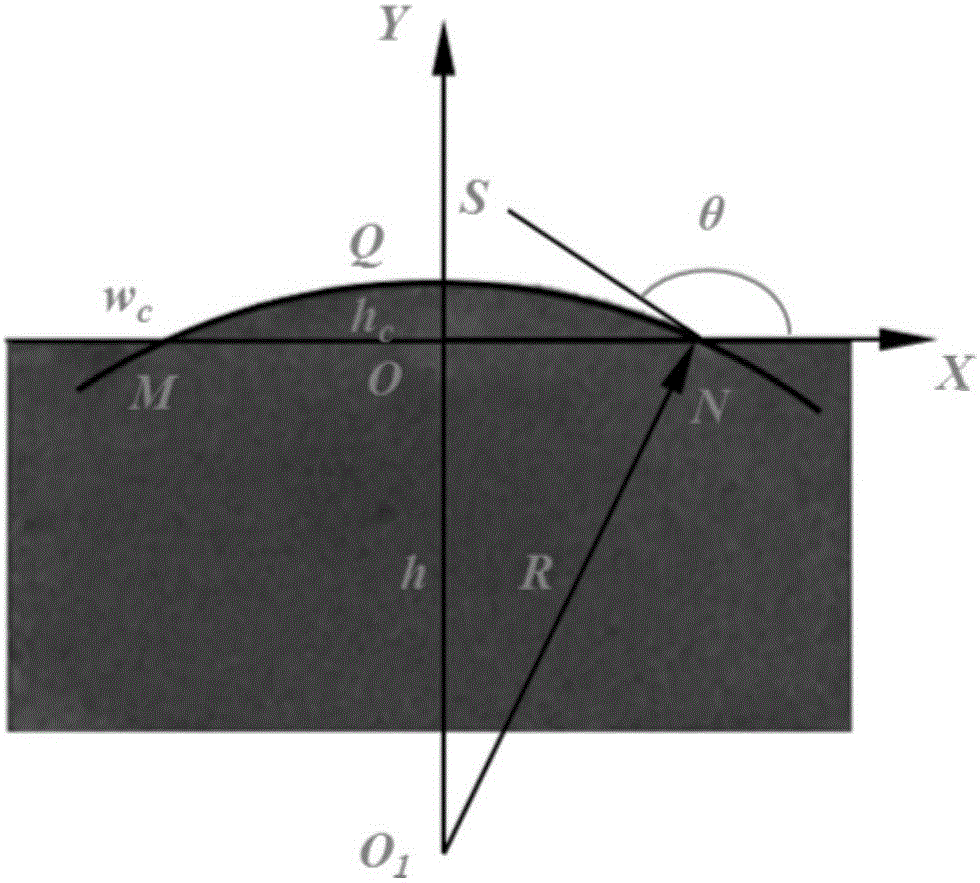

[0033] Such as figure 1 As shown, a cladding layer cross-section profile curve under the action of a broadband laser, cladding layer cross-section refers to the cross-section of a single cladding layer formed in laser cladding perpendicular to the laser movement direction, the cladding layer cross-sectional profile curve equation is ,

[0034] x∈[-w c / 2,w c / 2]

[0035] Among them, y is the ordinate of the cladding layer section profile curve in the coordinate system XOY, x is the abscissa, h c is the cladding layer height, w c is the width of the cladding layer, θ is the deposition angle, the XOY coordinate system takes the center of the bottom of the cladding layer as a circle O, the direction of the width of the cladding layer is the X axis, and the direction of the height of the cladding layer is the Y axis, h c 、w c Both and θ can be desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com