Rubber coating fiber cord fabric manufacturing method for conducting rubber coating through calender

A manufacturing method and calender technology, which is applied in the field of tire production, can solve the problems of high cord density at both ends of the rubber-coated fiber cord and low density in the middle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

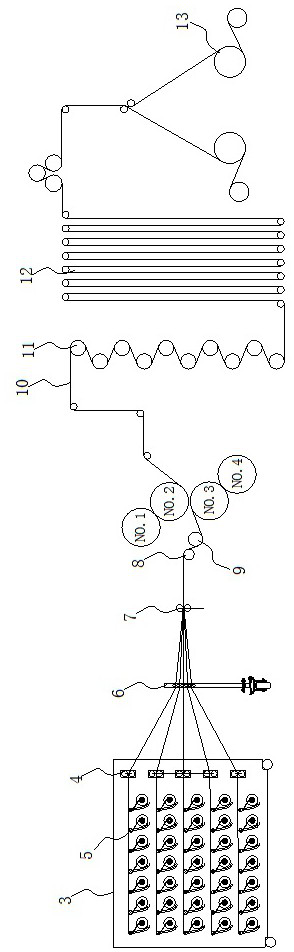

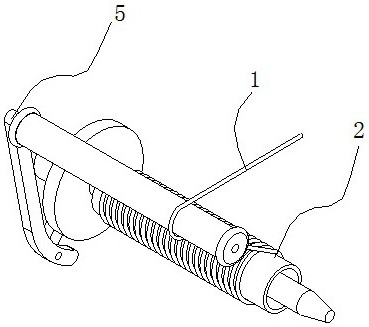

[0019] The spindle 2 used in the present invention, the four-roller calender, the coiling system 13, etc. are all commonly used equipment in the field, and the single fiber cord 1 used is a dipped nylon 66 cord with a specification of 1400dtex / 2. It is made of nylon 66 fiber filaments through twisting and dipping, and each cord is individually and continuously rolled onto a cylindrical paper tube to form a spindle 2, and the cords cannot have joints. The mixed rubber used is made of natural rubber, carbon black, accelerator, vulcanizing agent, anti-aging agent and other materials through internal mixer mixing and refining.

[0020] The spindle 2 is located in the spindle room, which has a temperature and humidity control system, the temperature is at least 3°C higher than the ambient temperature outside the spindle room, and the humidity is ≤50%. In the spindle room, 1400 spindles 2 are installed on both sides of the spindle frame 3, 700 spindles on each side, and the spindl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness range | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com