Method for preparing composite material through hot-pressing strengthening

A composite material and reinforcement technology, applied in the field of composite material manufacturing, can solve the problems of difficult to meet model product design indicators and mission requirements, sacrificing aircraft payload, and difficult to meet complex limit flight conditions and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

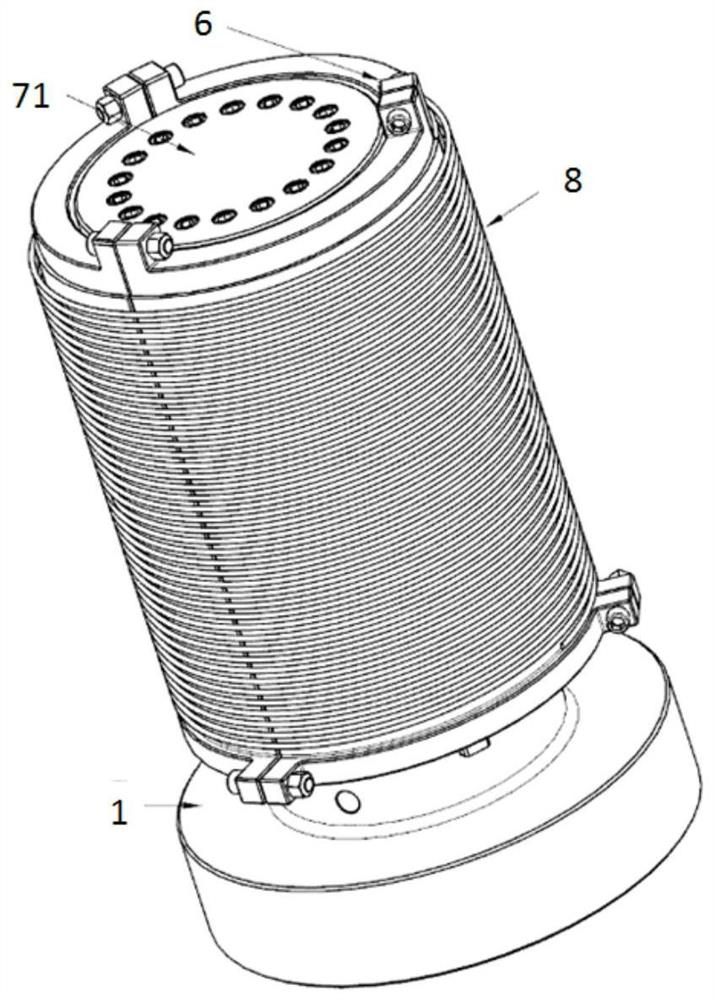

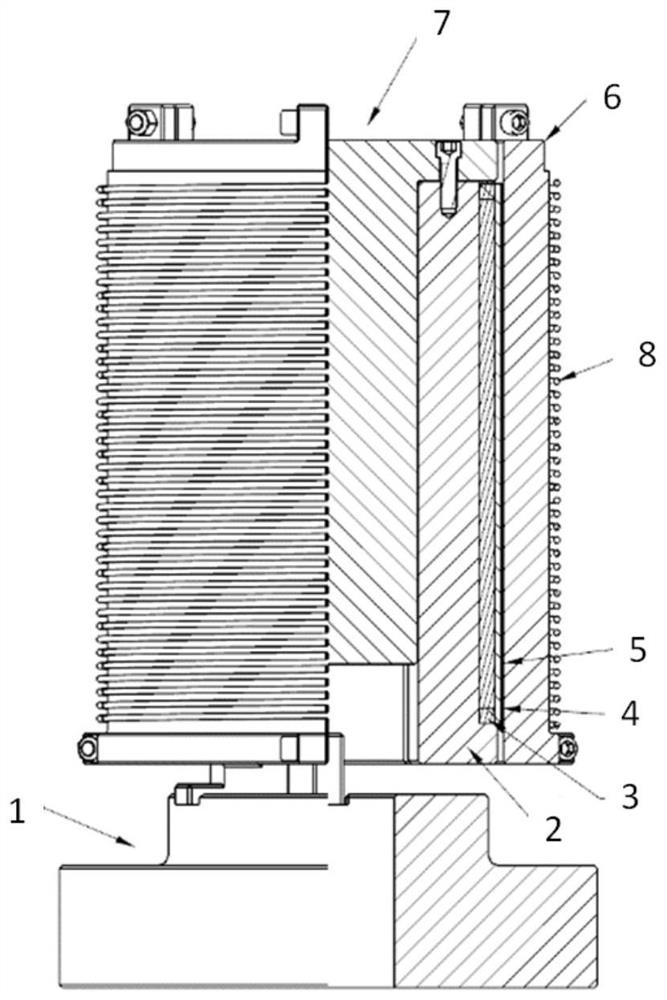

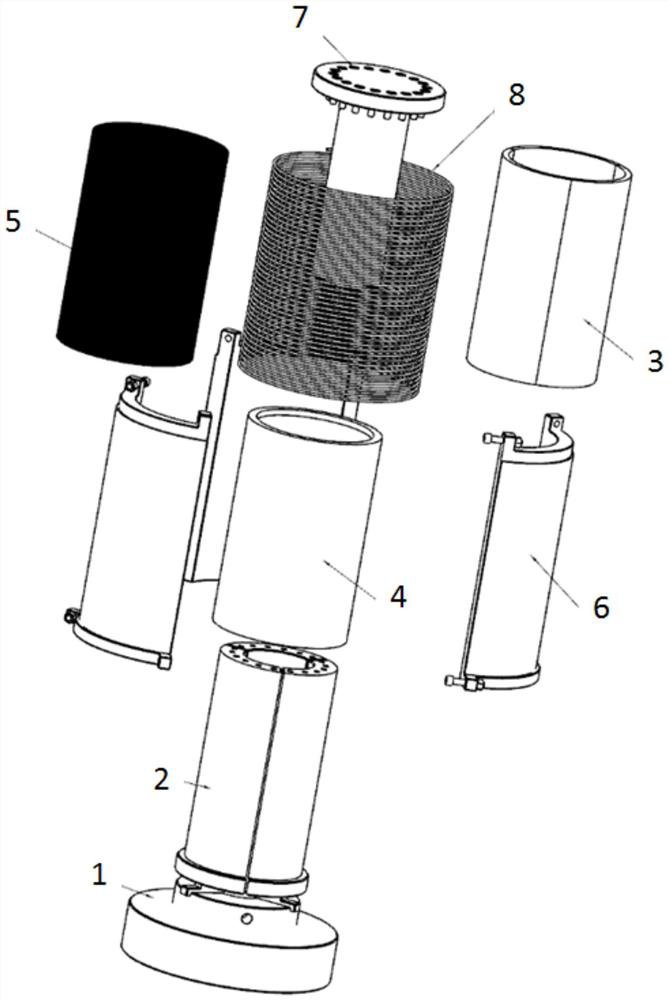

[0051] A device for preparing composite materials by hot pressing, such as Figure 1-3 , the device includes a liner 3, an outer hoop 6 and a high-frequency induction coil 8; the composite material matrix 4 is set outside the liner 3, the composite material reinforcement 5 is laid outside the matrix 4, and the outer hoop 6 is arranged on the reinforcement 5, the high-frequency induction coil 8 is located outside the outer hoop 6. Under the inner and outer support of the lining plate 3 and the outer hoop 6 and the heating environment of the high-frequency induction coil 8, the matrix 4 presses the reinforcement 5 into the semi-solid matrix 4 by applying external pressure to the outer hoop 6. After completion, the purpose of improving the strength and tensile properties of the matrix 4 is achieved.

[0052] The number of lining plates 3 is three, the gap between each lining plate 3 is not more than 0.1mm, and the thickness of the lining plates 3 is not less than the difference be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com