Anti-ultraviolet aging release film

A technology of anti-ultraviolet and release film, which is applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc. Normal use and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

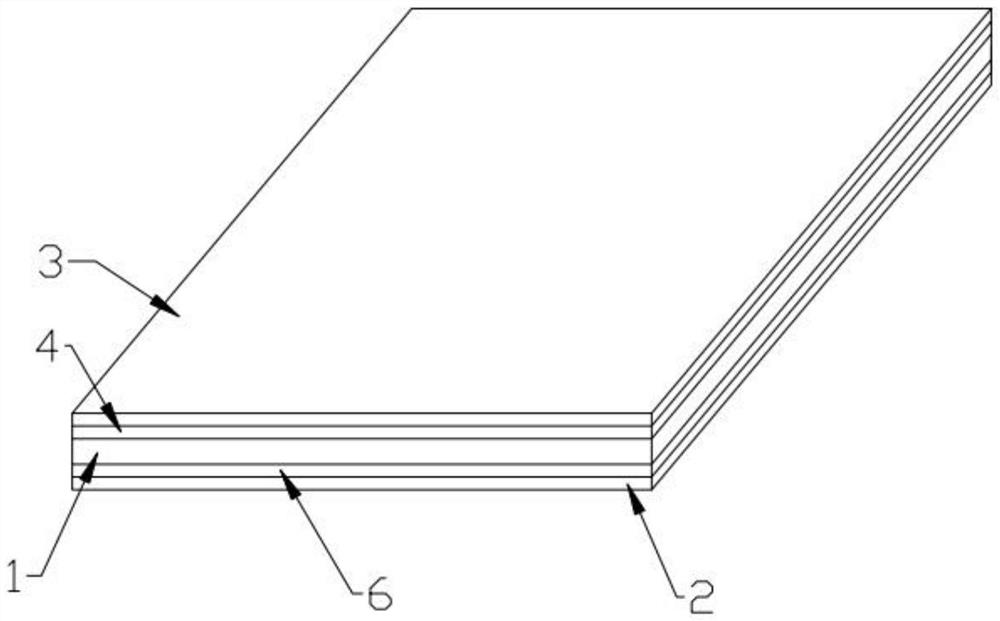

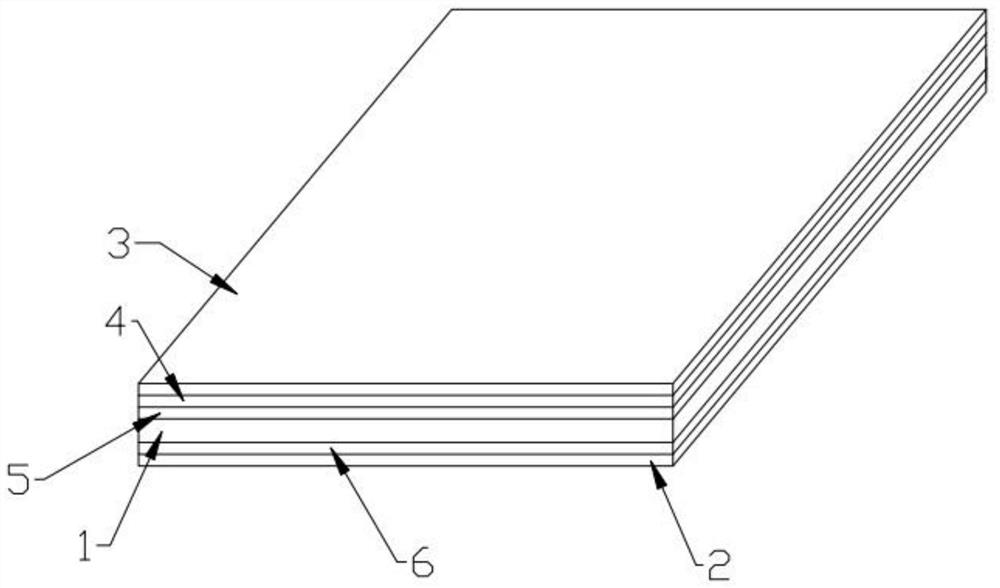

[0023] Such as figure 1 As shown, the anti-ultraviolet aging release film includes a PE base layer 1, one side of the PE base layer 1 is provided with a peeling layer 2, and the other side of the PE base layer 1 is provided with an ultraviolet isolation layer 4, and the ultraviolet isolation layer 4 is connected to the PE base layer 1. The side facing away from each other is provided with a reflective layer 3; the release layer 2 and the PE base layer 1 are bonded by a release agent coating 6; in this embodiment, the outer side of the PE base layer 1 is provided with an ultraviolet isolation layer 4 and a reflective layer 3. The reflective layer 3 is used to reflect sunlight and reduce the absorption of light by the release film. The ultraviolet isolation layer 4 isolates ultraviolet rays, blocks ultraviolet rays ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com