PC/PMMA composite material, preparation method thereof and electronic terminal shell

A composite material, electronic terminal technology, applied in the field of millimeter wave communication, can solve the problems of short electromagnetic wave wavelength, weak penetration ability, affecting service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] According to another aspect of the present invention, there is also provided a method for preparing the above-mentioned PC / PMMA composite material, comprising the following steps: S1, mixing raw materials comprising PC, PMMA, thermally conductive fillers, reinforcing fillers and compatibilizers to obtain Mixed material; S2, shape the mixed material to obtain PC / PMMA composite material.

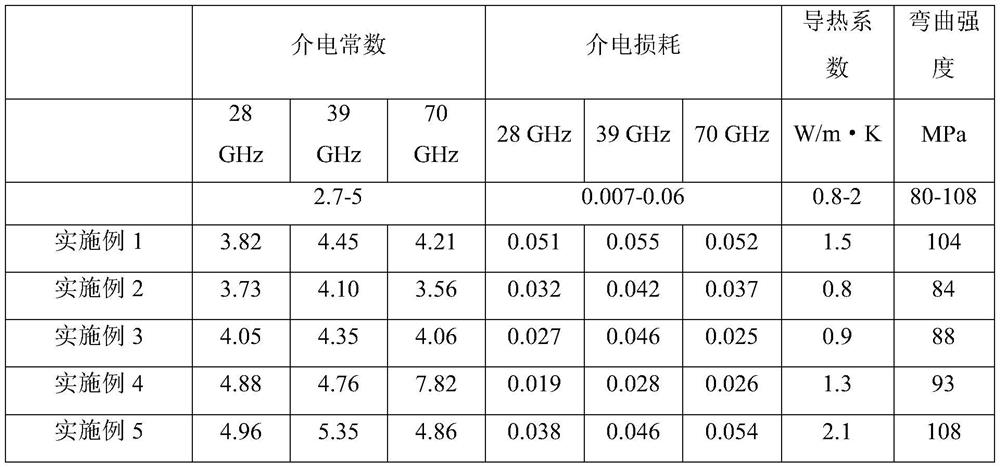

[0027] The present invention adds thermally conductive fillers and reinforcing fillers to the material formulation system. The thermally conductive fillers and reinforcing fillers can effectively improve the interface bonding between the fillers and the matrix material under various auxiliaries and mixing process conditions, and increase the uniformity of the mixing of the composite materials. and density, so that the PC / PMMA composite material has high strength, high toughness and high thermal conductivity, and can also exhibit low dielectric constant and dielectric loss characteristics...

Example

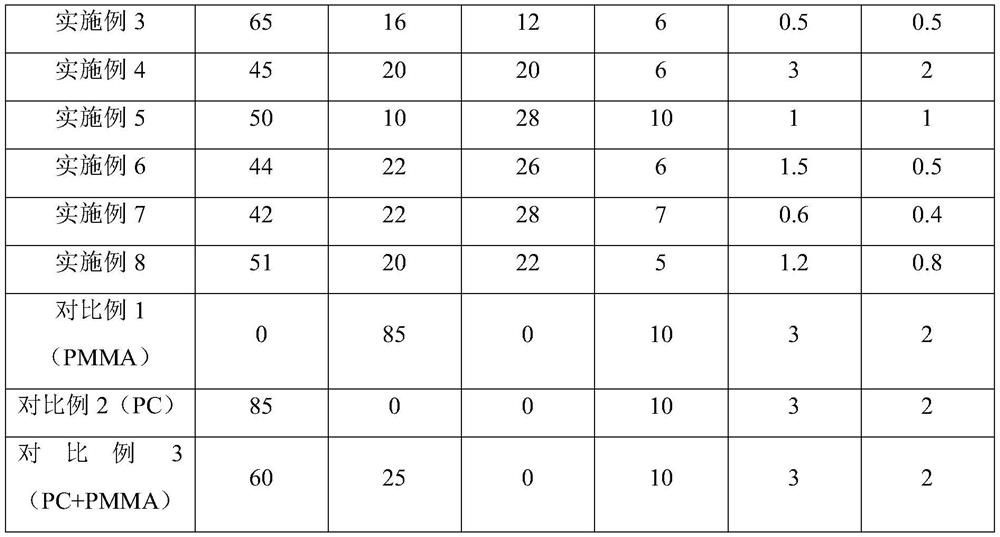

[0034] Examples 1 to 6

[0035] A PC / PMMA composite material is provided in the present embodiment, comprising the following steps:

[0036] Mix PC, PMMA, expanded graphite powder, alumina, zirconia, compatibilizer and anti-aging agent at a stirring speed of 20r / min to obtain a mixed material, wherein the compatibilizing agent is PP-g-MA, and the anti-aging agent is PP-g-MA. is 4,4'-thiobis(6-tert-butyl-3-methylphenol), and the mass ratio of each component is shown in Table 1;

[0037] The mixture is extruded and granulated at a temperature of 210° C. to obtain PC / PMMA composite particles, and the PC / PMMA composite particles are injection-molded to obtain a PC / PMMA composite material.

Example Embodiment

[0038] Example 5

[0039] The difference between this embodiment and Embodiment 1 is:

[0040] The thermally conductive filler is h-boron nitride.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap