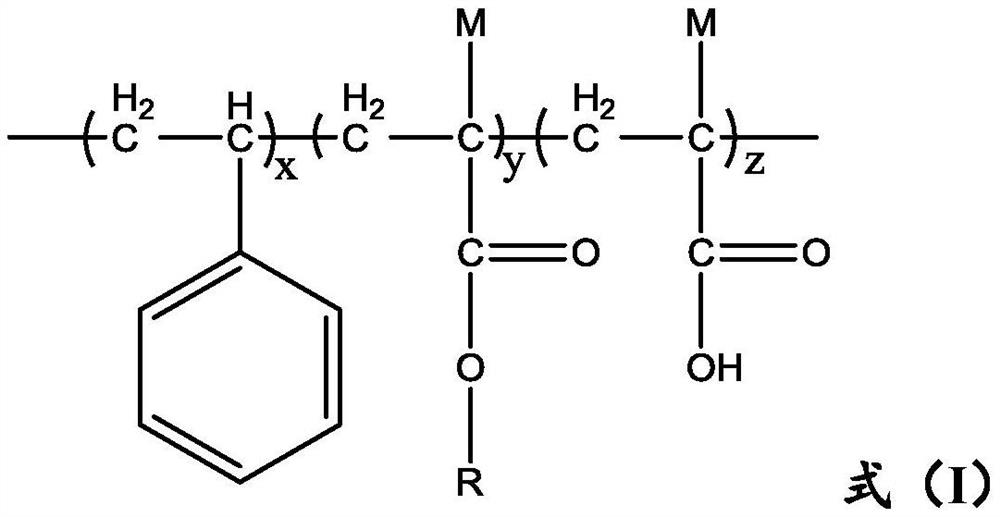

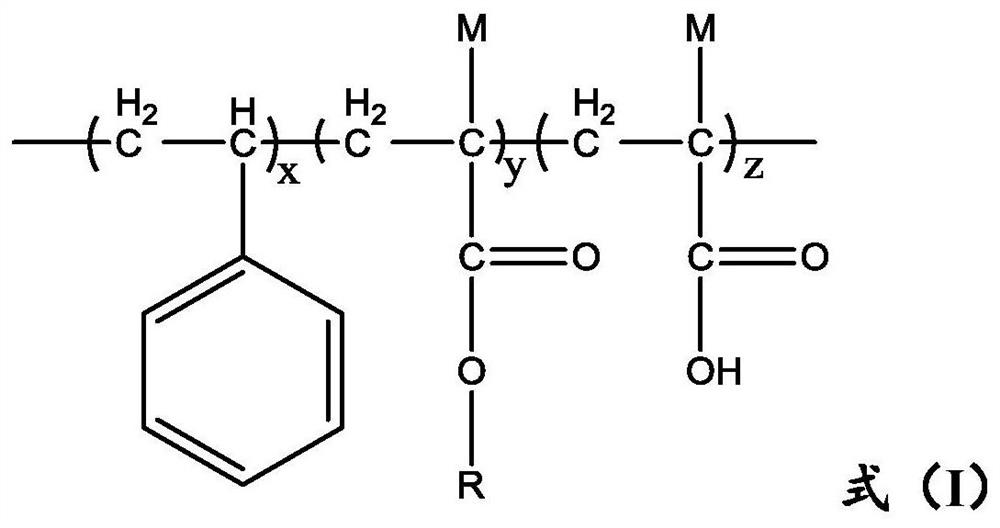

Modified styrene-acrylate resin capable of prolonging uncovering time of thermal foaming ink

An acrylate and styrene technology, which is applied in the field of modified styrene-acrylate resin and its preparation, can solve the problems that the printing process cannot be interrupted for a long time, the plug is blocked, and the contact of the substrate surface is not reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0063] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

preparation example 1

[0065] Add the water of 36.5% mass fraction, the styrene-acrylic ester resin CSE-1000 of 60% mass fraction, the surfactant SR-10 of 1% mass fraction of Aidike Company in the four-necked bottle, stir and pass into nitrogen For protection, the water bath is heated to 80°C. When the temperature reaches 80°C, 2% mass fraction of the silane coupling agent KBM-503 and 0.5% mass fraction of the 5% KPS aqueous solution are added dropwise at a constant speed. The temperature is controlled to maintain 80-85°C, and the dropwise addition time is 1 hour. After completion of the dropwise addition, the temperature was maintained at 80° C. for 2 hours, and the temperature was lowered to room temperature. The modified styrene-acrylate resin was obtained as a white viscous liquid.

Embodiment 1

[0067] In the mixture of ethanol and water, add sodium hydroxide to adjust the pH=8.5, keep the temperature at 55°C under heating, slowly add the modified styrene-acrylic resin prepared in Preparation Example 1 or Aurfon 5022 (solid form) or styrene - Acrylate resin CSE-1000 (in solid form) until it is fully dissolved. Cool to room temperature to form a resin solution. Mix in pigment, Megafac R-47, and other solvents in turn, mix well, rotate at 1000rpm, mix thoroughly for 30 minutes, add drier and mix for 5 minutes, see Table 1 for specific proportions.

[0068] The mixed ink was left overnight, filtered, and filled into HP ink cartridge packages. After 24 hours, print the test on the BOPP film, monitor the process, and after the writing is dry, slide your finger to evaluate the adhesion of the writing. The test scoring criteria and results are shown in Table 2. The result evaluation scores in Table 2 are between 1 and 10, where 1 is the worst and 10 is the best.

[0069] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com