Multifunctional coated glass

A multifunctional, glass technology that can be used in building components, lighting and heating equipment, sound insulation, etc., to solve problems such as detachment and damage of lighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

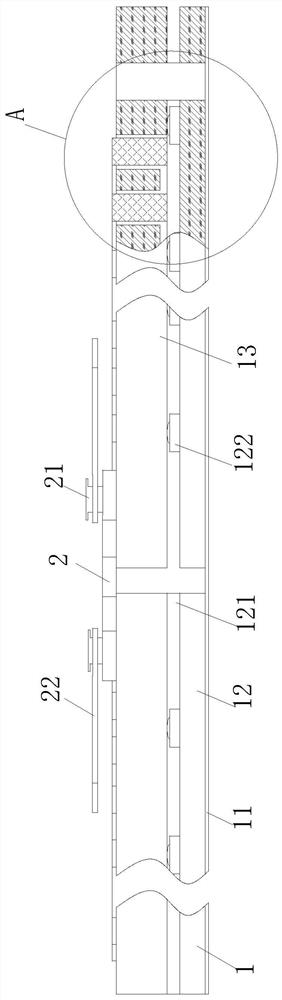

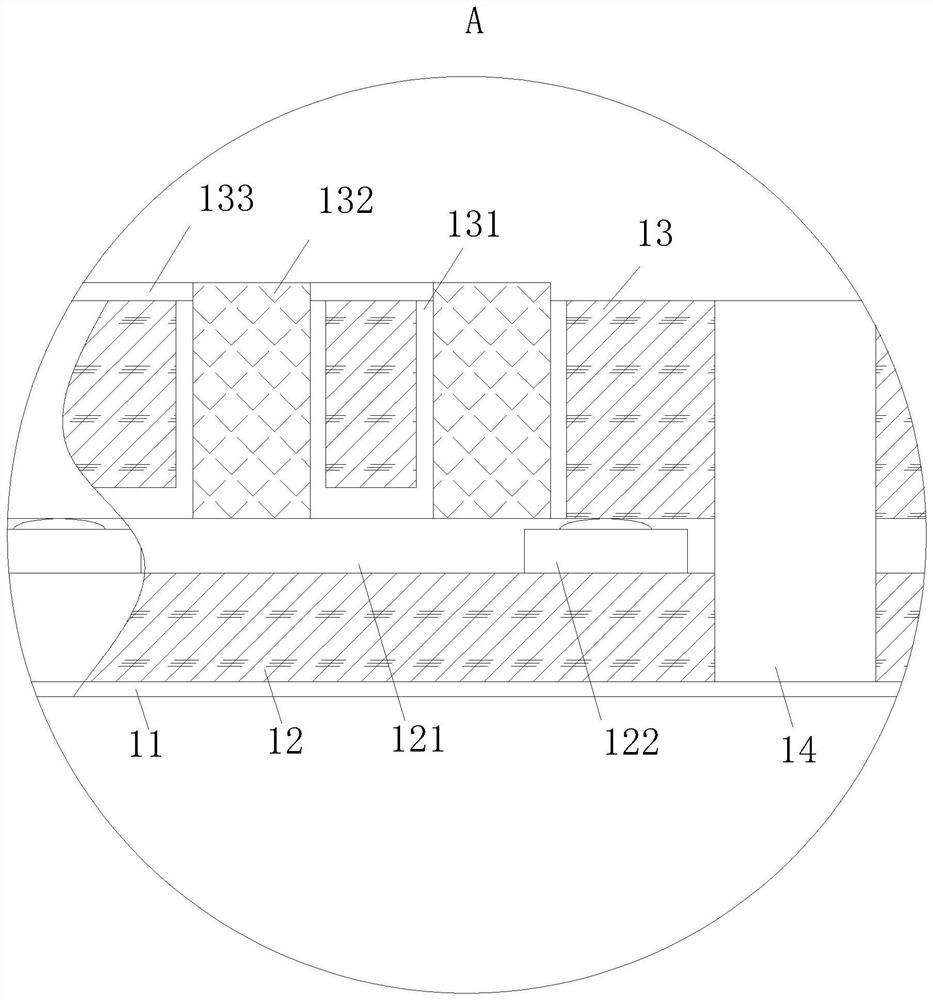

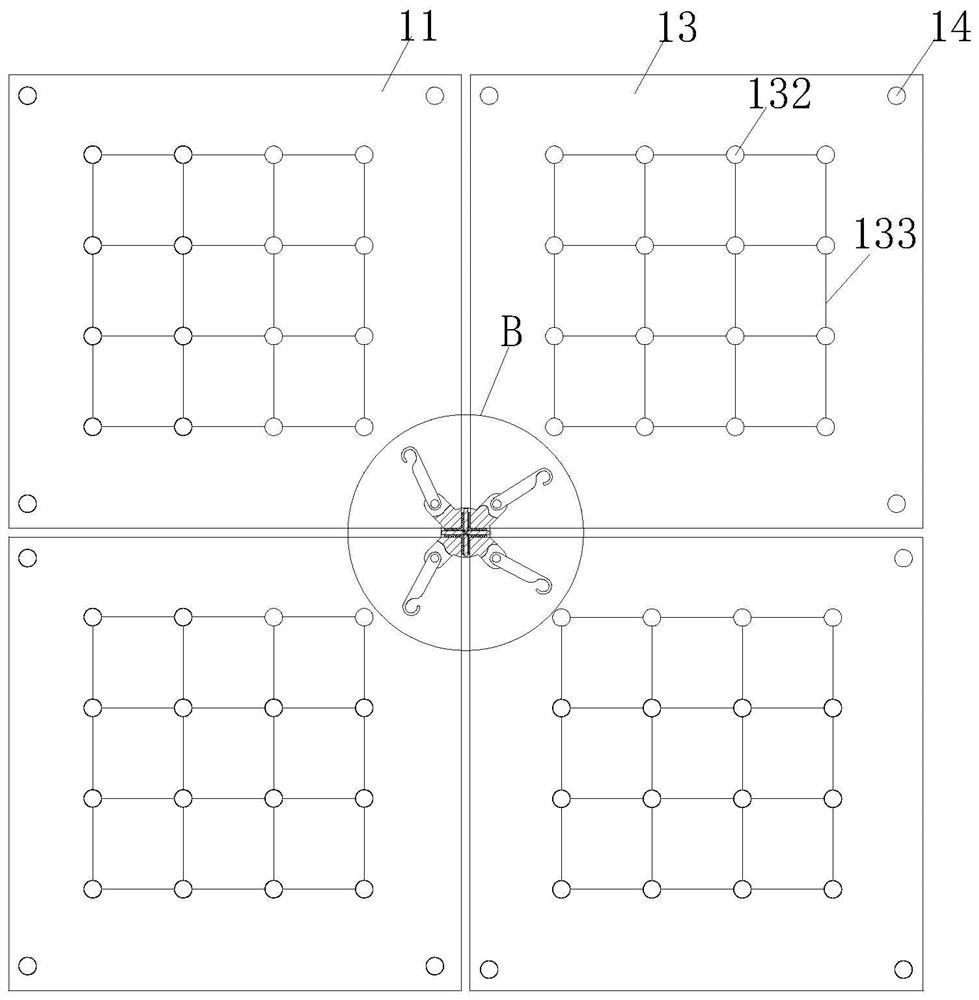

[0026]As a specific embodiment of the present invention, through holes 14 are opened on the inside of the four right angles of the body 1, and the four adjacent bodies 1 are connected by buckles 2; the buckles 2 are attached to the inner layer 13 On the surface, the buckle 2 is in the shape of a "ten", and each end of the buckle 2 is provided with a connecting rod 21, and the connecting rod 21 is inserted into the through holes 14 on the four adjacent bodies 1; through the buckle 2, the adjacent The main body 1 is connected together; when the main body 1 is connected, the skeleton is first built by external connection, the main body 1 is put into the skeleton, and then the four adjacent main bodies 1 are fastened together by the buckle 2, and the connecting rod 21 is attached to the buckle 2 Inserted into the through hole 14, so that the right angles of the four adjacent bodies 1 are connected together by the buckle 2, and the design of the buckle 2 is also beneficial to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com