Electromagnetic bearing test device for main helium fan

A technology of main helium blower and electromagnetic bearing, which is applied in the direction of mechanical equipment, machine/engine, pump control, etc., and can solve the problems of no equivalent capacity, similar structure, no model, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

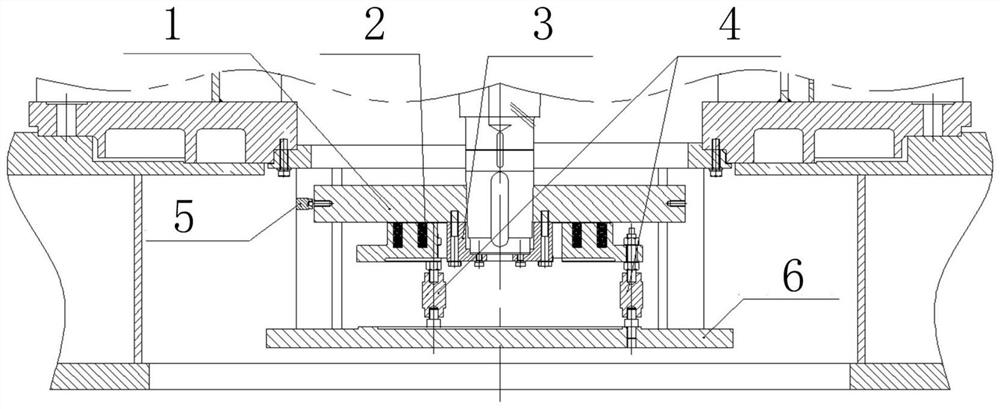

Embodiment 1

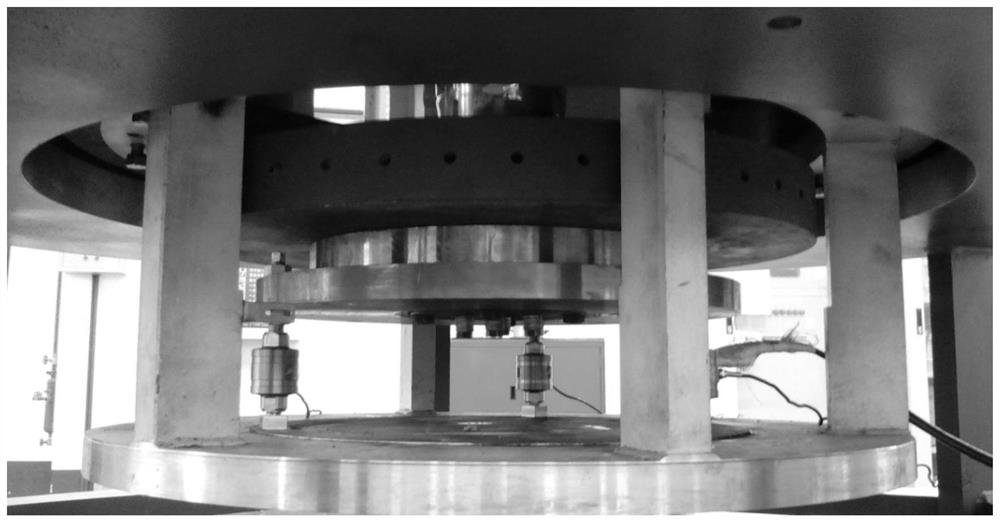

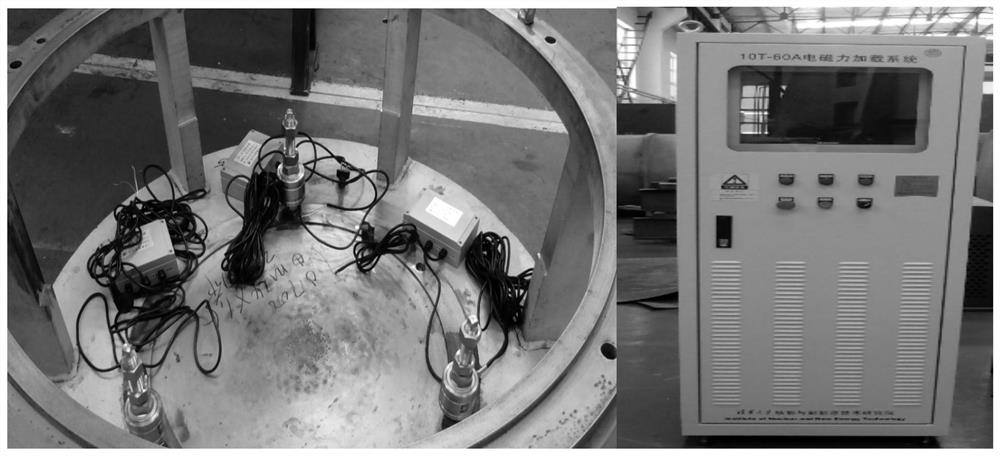

[0031] The loader includes: electromagnetic force part, control cabinet, digital acquisition and control system (speed, force, etc.), counterweight plate, etc. The loader loads the motor counterweight plate through electromagnetic force (non-contact). The loading force can be adjusted with the motor speed. The loading force range is 0-6000kg. During the drop test, the main helium fan 4000r / min corresponds to a loading force of 4500kg. Power supply: 220V, 50Hz. The loader counterweight plate 1 is made of 40Cr material, which can simulate the mass and moment of inertia of the main impeller, and use the suction provided by the loader to simulate the aerodynamic force generated when it rotates. The loader counterweight plate 1 is cantilevered on the main impeller. The helium blower drives the motor shaft extension end, the loader counterweight plate 1 and the shaft adopt a tapered interference fit, the taper is 1:20, and the interference is 0.3mm. It is hot-packed during assembly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com