Concrete pipe and processing technology thereof

A technology for concrete pipes and pipe bodies, which is applied to pipes, rigid pipes, manufacturing tools, etc., and can solve problems such as rubber rings easily detached from concrete pipes, concrete pipes not tightly sealed, and concrete pipe fluid leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

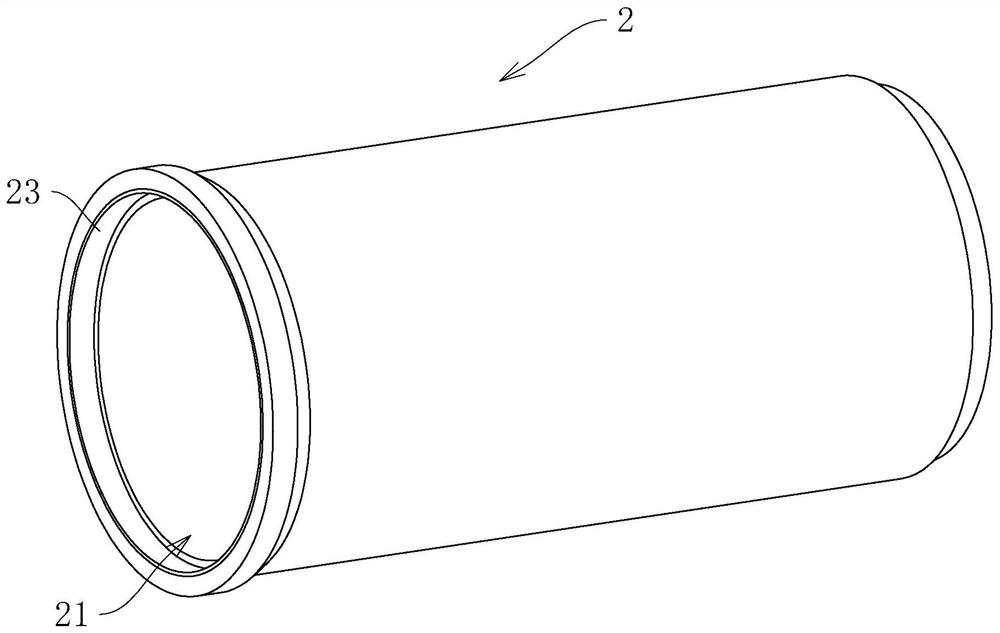

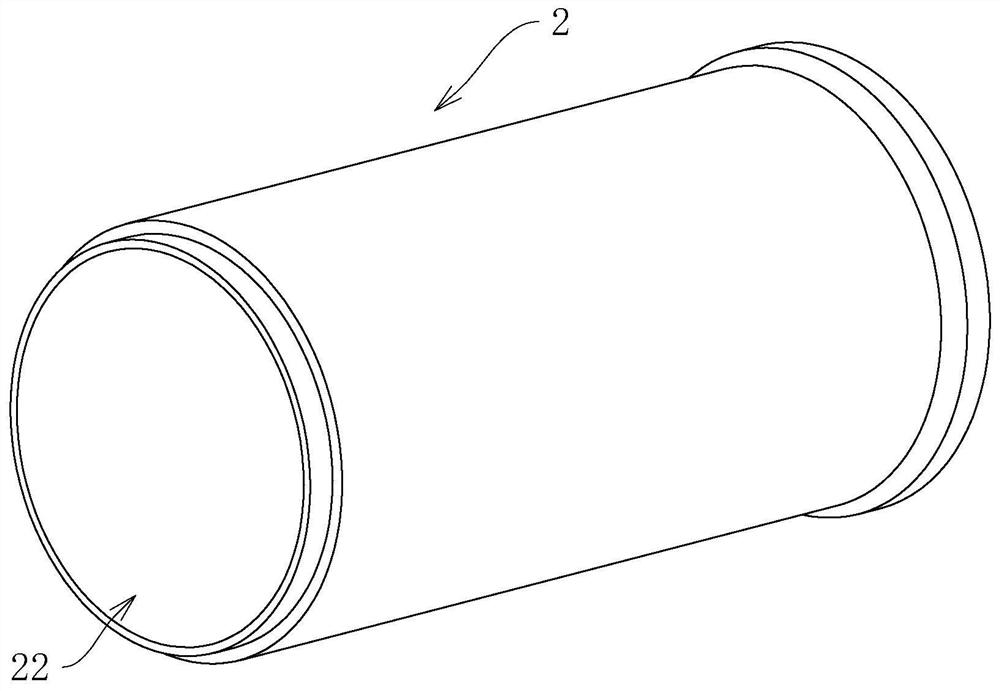

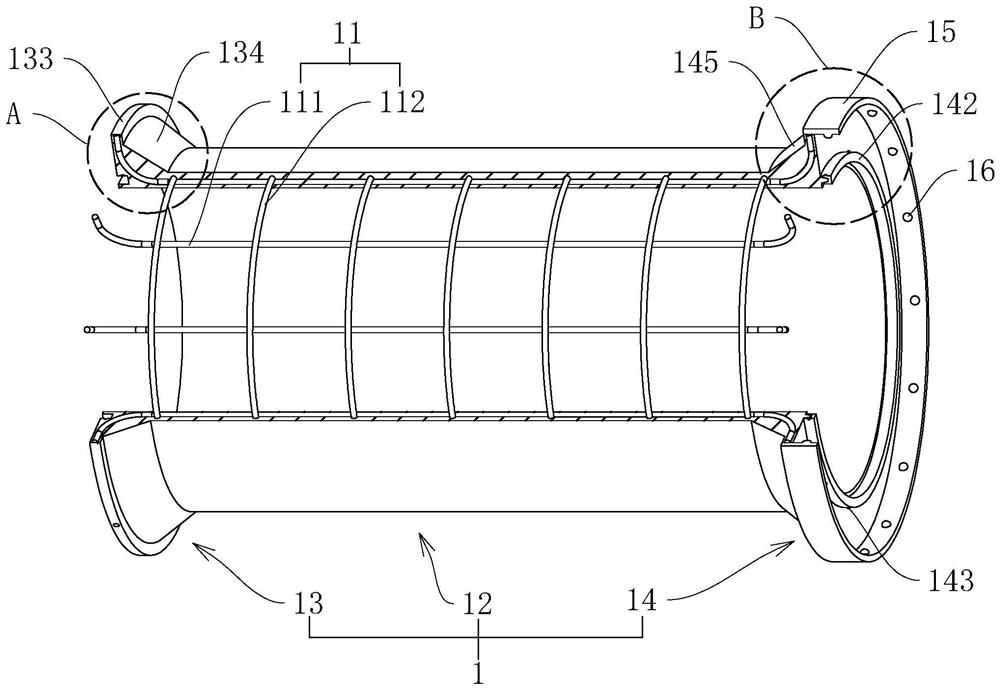

[0048] refer to image 3 , is a concrete pipe disclosed by the present invention, comprising a pipe body 1 and a reinforcement frame 11 arranged in the pipe body 1, the reinforcement frame 11 is formed by welding the main reinforcement 111 and the ring-shaped stiffening reinforcement 112, and the main reinforcement 111 and the reinforcement reinforcement 112 are mutually Vertical mesh. The pipe body 1 includes a middle part 12 and a receiving part 13 and an insertion part 14 respectively located at two ends of the middle part 12, combined Figure 4 and Figure 5The end surface of the receiving part 13 is provided with an annular groove 131, and the end surface of the insertion part 14 is provided with an annular protrusion 141. The section of the protrusion 141 along the axial direction of the pipe body 1 is trapezoidal, and the protrusion 141 The area of the end surface close to the insertion portion 14 is greater than the area of the end surface of the protrusion 141 a...

Embodiment 2

[0056] A processing technology for a concrete pipe based on the concrete pipe in Embodiment 1 disclosed by the present invention includes the following production steps:

[0057] S1: Fabrication of reinforcement frame: vertically weld stiffener 112 on main reinforcement 111, stiffener 112 and main reinforcement 111 are perpendicular to each other to form a mesh, after reinforcement frame 11 is welded and formed, rubber ring 15 and main reinforcement 111 are fixed, and then reinforcement frame 11 is put into in the mold.

[0058] S2: Centrifugation: Start the centrifuge to drive the mold to rotate, and at the same time add concrete to the mold until the centrifuge completes the concrete tube forming.

[0059] S3: finishing treatment: use an iron trowel, a wooden trowel or an aluminum alloy scraper to repeatedly press and wipe the surface of the receiving ring 133 and the connecting ring 144 .

[0060] S3 includes the following sub-steps:

[0061] S31: After the centrifugation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com