Municipal waste incineration device

A waste incineration, municipal technology, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as being unsuitable for municipal engineering, equipment damage, and insufficient incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

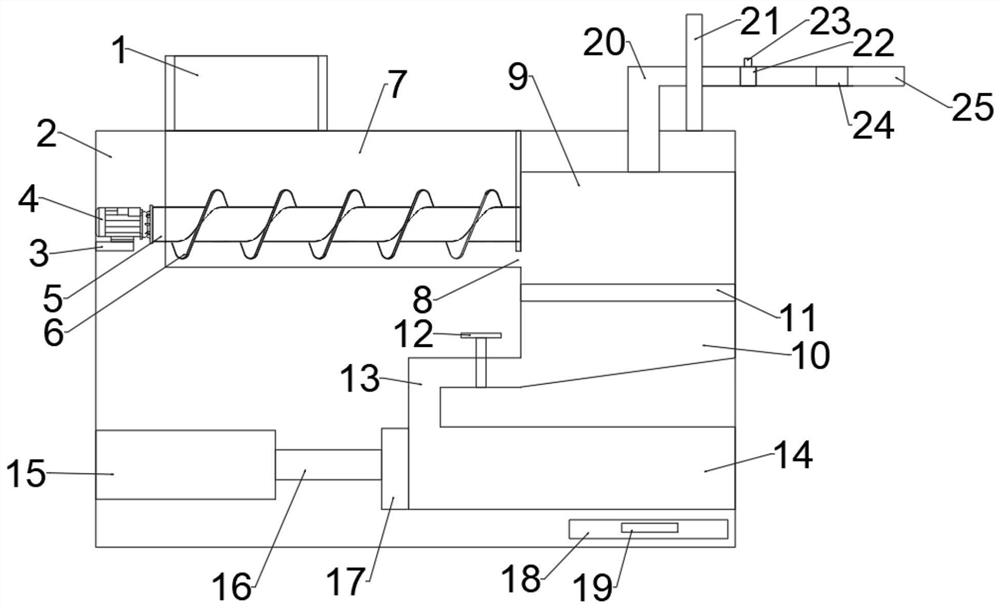

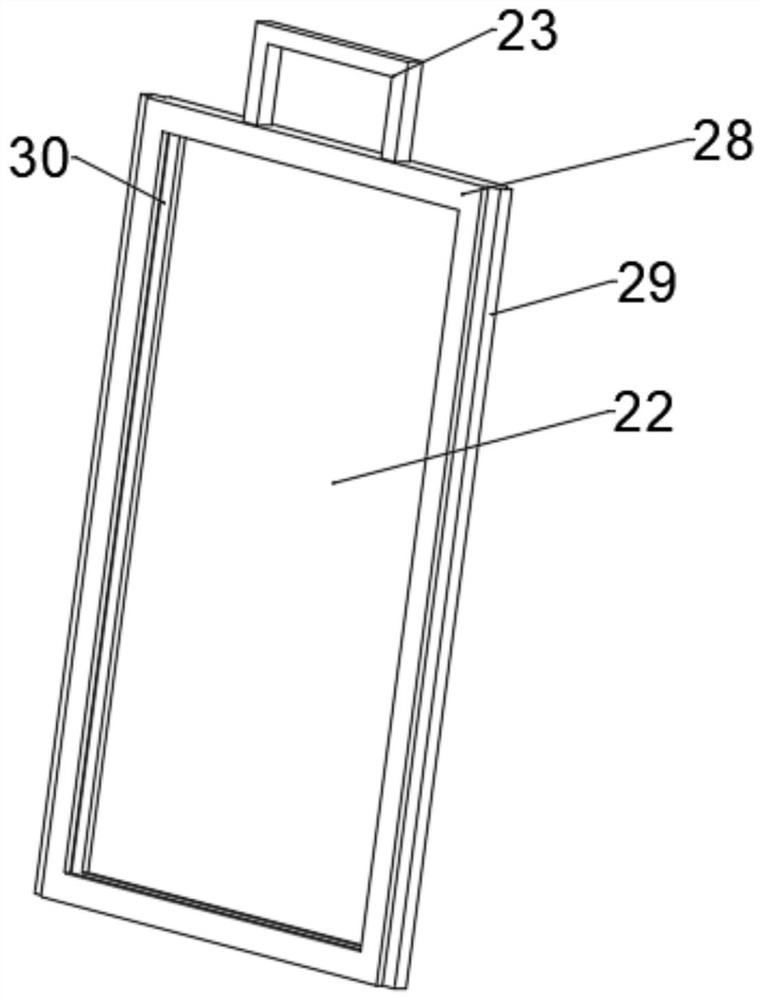

[0033] refer to Figure 1 ~ Figure 4 , a municipal waste incineration device, comprising a box body 2, a feeding box 7 is connected with a bolt on the upper left side of the box body 2, an incineration box 9 is connected with a bolt on the right side of the feeding box 7, and a bolt on the left side of the incineration box 9 is Connected with a transition pipe 13, the end of the transition pipe 13 away from the incineration box 9 is bolted to a compression box 14, the top of the incineration box 9 is bolted to an outlet pipe 20, and the bolt on the outlet pipe 20 is connected to a condensing device 21, and the right side of the condensing device 21 The side bolts are connected with a drying plate 22, the end of the air outlet pipe 20 away from the incineration box 9 is bolted with a purification plate 24, and the side of the purification plate 24 away from the air outlet pipe 20 is bolted with an air outlet 25, and the outside of the drying plate 22 is provided with a limited s...

Embodiment 2

[0041] refer to Figure 5 , a municipal waste incineration device. Compared with Embodiment 1, this embodiment is provided with a running mechanism under the box body 2. The running mechanism includes a rolling wheel 26 and a brake plate 27. The four corners of the box body 2 are connected by bolts. There is a scroll wheel 26, and the bolt on the scroll wheel 26 is connected with a braking plate 27. The rolling wheel 26 is used to make the device move freely, which is convenient for the return and embezzlement of the device. The braking plate 27 is used to keep the device stable when moving to a designated position. Make it not move during operation, ensure its purification effect and increase its applicability.

[0042] Working principle: use the rolling wheel 26 to make the device move freely, which is convenient for the device to be returned to storage and misappropriation; use the brake plate 27 to keep the device stable when moving to the designated position, so that it w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com