Nitrogen preparing device having with refrigerating unit single tower, and method

A refrigerating unit and single-tower technology, applied in cold treatment separation, refrigeration and liquefaction, liquefaction, etc., can solve the problems of low working efficiency of the device, low degree of air liquefaction, nitrogen and liquid nitrogen output not meeting the predetermined requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

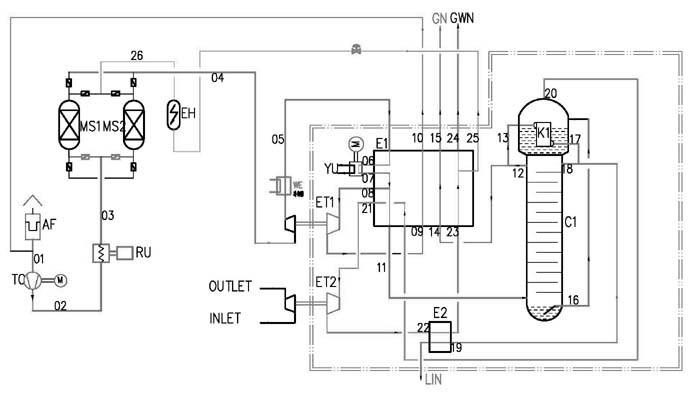

[0013] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, a single-tower nitrogen-generating device with a refrigerating unit includes an air filter AF to send filtered air to a turbo air compressor TC through a pipeline 01, and the turbo air compressor TC pressurizes the air It is sent to the pre-cooling unit RU through the pipeline 02, and then sent to the molecular sieve purifier group MS through the pipeline 03 to remove the moisture in the air, CO 2 、C 2 h 2 After the harmful impurities are adsorbed, it enters the supercharging end of the high-temperature expander ET1 through the pipeline 04 for supercharging. After the supercharging, it is cooled by the cooler WE in the pipeline 05 and sent to the main heat exchanger E1, and then reaches the refrigeration unit YU through the pipeline 06. After the air enters the main heat exchanger E1 again through the pipeline 07, it is divided into two paths, and one p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com