A tbm tool pressure equalization wear detection system and method

A wear-balancing and detection system technology, applied in the TBM field, can solve problems such as TBM cutter head wear accidents, accelerated tool wear, TBM shutdown, etc., to achieve the effects of reducing the risk of shutdown, saving costs, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

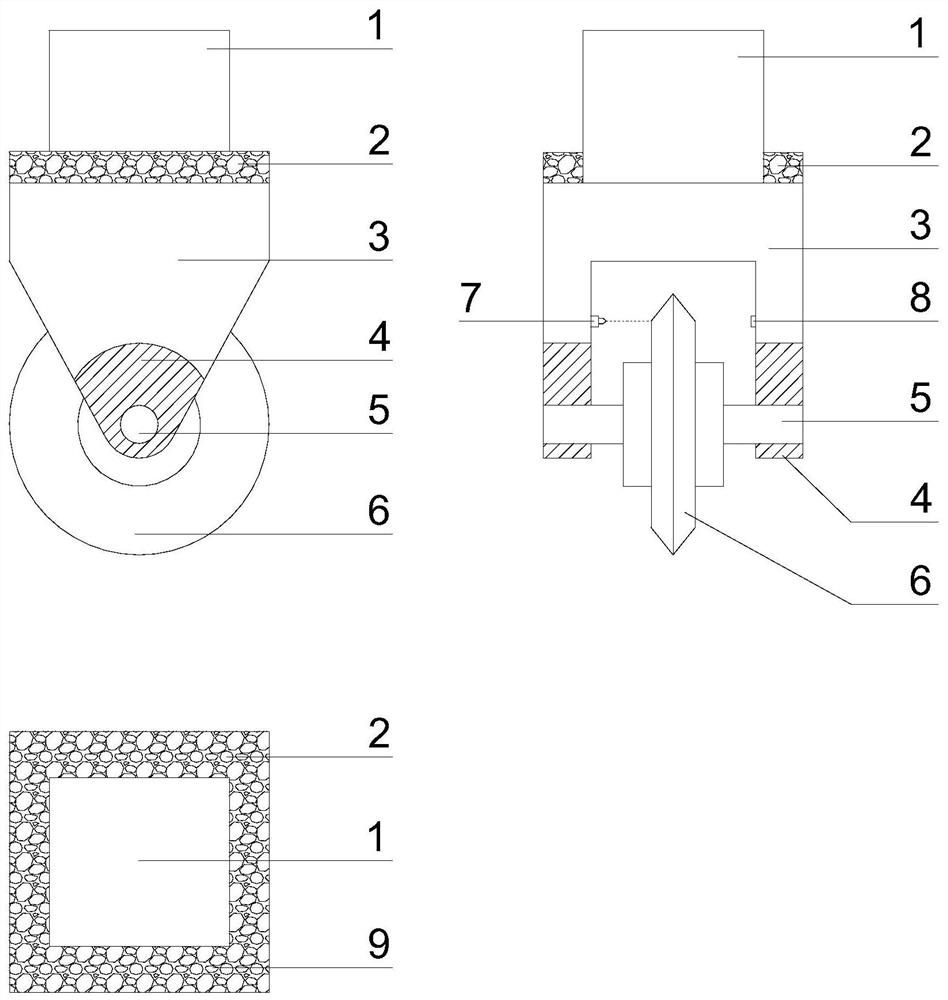

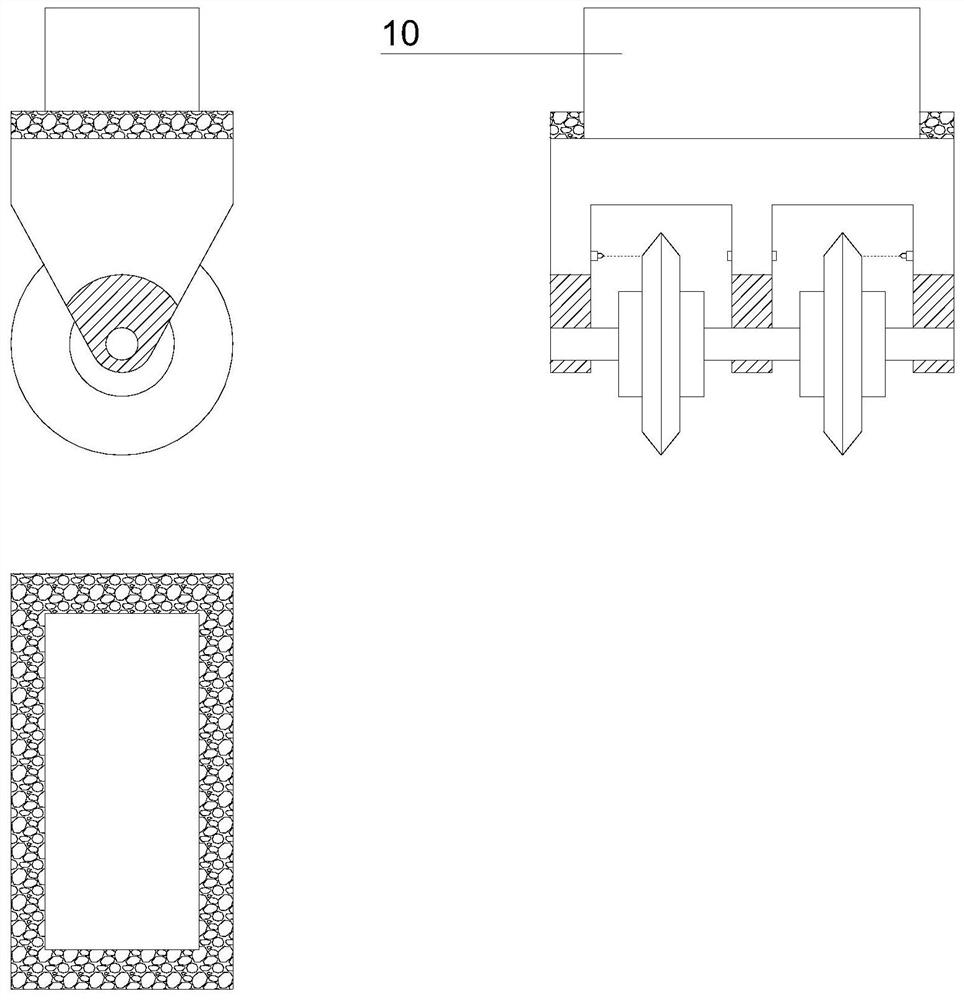

[0051] Such as Figure 1-6 As shown, Embodiment 1 of the present disclosure provides a TBM cutter head tool pressure equalization and wear detection system, including a single hob 9 or double hob 10 , a cutter head 11 , a cutter head mounting seat 12 and a hydraulic base 17 .

[0052] The schematic diagram of a single hob is shown in figure 1 As shown, the schematic diagram of the double hob is shown in figure 2 As shown, the single hob 9 or the double hob 10 all include a magnetic latch 1, a buffer pad 2, a hob seat 3, a hob shaft support 4, a hob shaft 5, a hob 6, a laser emitter 7 and Laser receiver 8.

[0053] In this embodiment, the magnetic plug 1 is a square structure matching the magnetic square hole 14 .

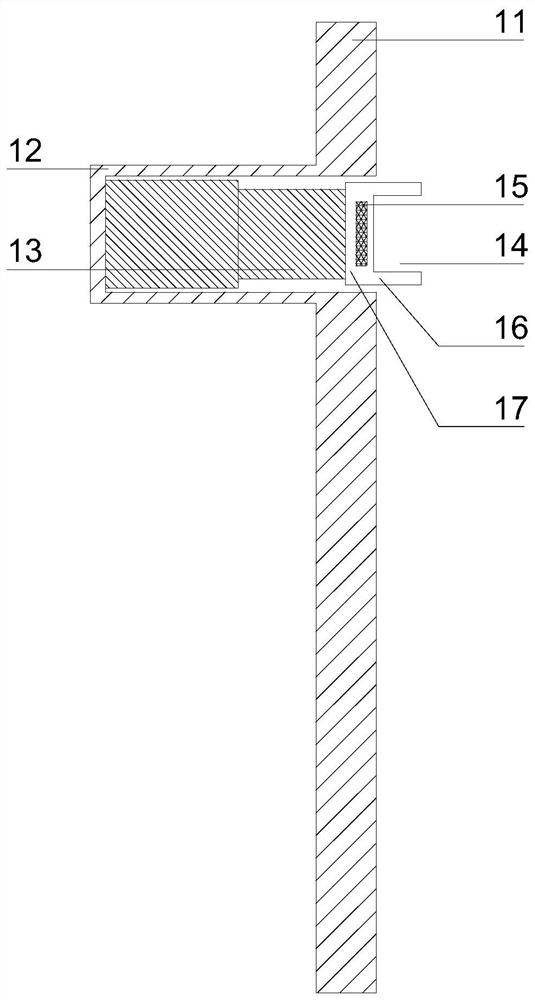

[0054] Such as image 3 As shown, the cutter head mounting base 12 is integrally cast with the cutter head 11 , the hydraulic base 17 includes a hydraulic rod 13 and a magnetic socket 16 , and the magnetic socket 16 includes a magnetic square hole 14 and an ele...

Embodiment 2

[0073] Embodiment 2 of the present disclosure provides a TBM tool pressure balanced wear detection method, using the TBM tool pressure balanced wear detection system described in Embodiment 1, including the following steps:

[0074] A. Weld and fix the hydraulic rod to the bottom of the cutterhead mount, and weld and fix the magnetic socket to the top of the hydraulic rod;

[0075] B. Turn off the electromagnet, insert the single hob (double hob) into the magnetic square hole through the magnetic latch to ensure that the direction of the blade is circular. At this time, start the electromagnet to complete the magnetic fixation;

[0076] C. Start the cutter head for excavation. When the TBM encounters soft and hard uneven ground, the pressure on individual cutters exceeds its rated pressure. At this time, the pressure-sensitive sensor in the hydraulic rod sends an overload signal and the hydraulic rod shrinks to reduce the pressure on the cutter. up to less than its rated value...

Embodiment 3

[0080] Embodiment 3 of the present disclosure provides a tunnel boring machine, including the TBM tool pressure equalization wear detection system described in Embodiment 1 of the present disclosure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com