Energy-saving laminating machine heating and cooling buffering method and system

A buffering method and laminator technology, which can be used in photovoltaic power generation, sustainable manufacturing/processing, electrical components, etc., and can solve problems such as large heating and cooling rates and temperature changes, component wrinkles, and material shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

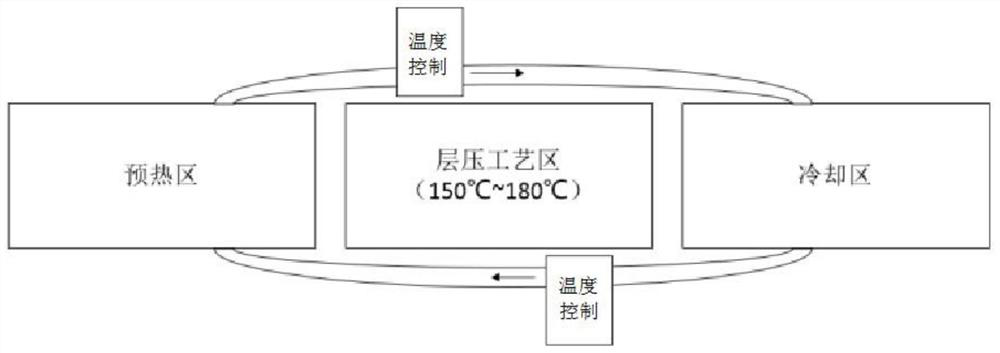

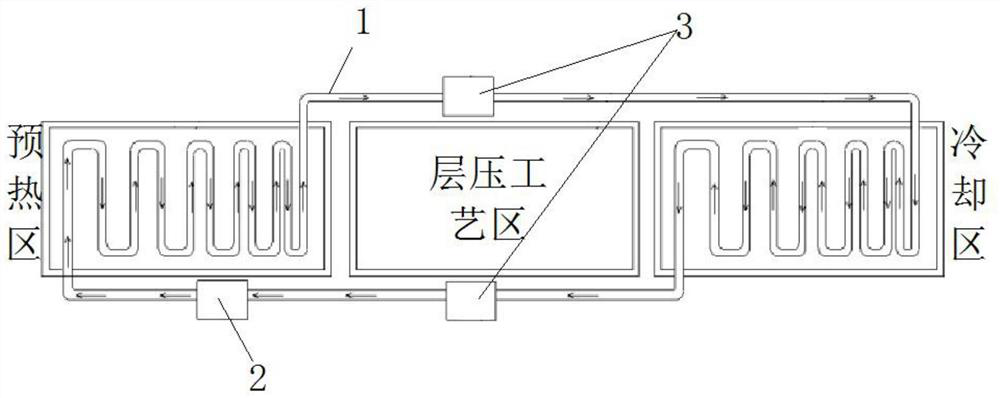

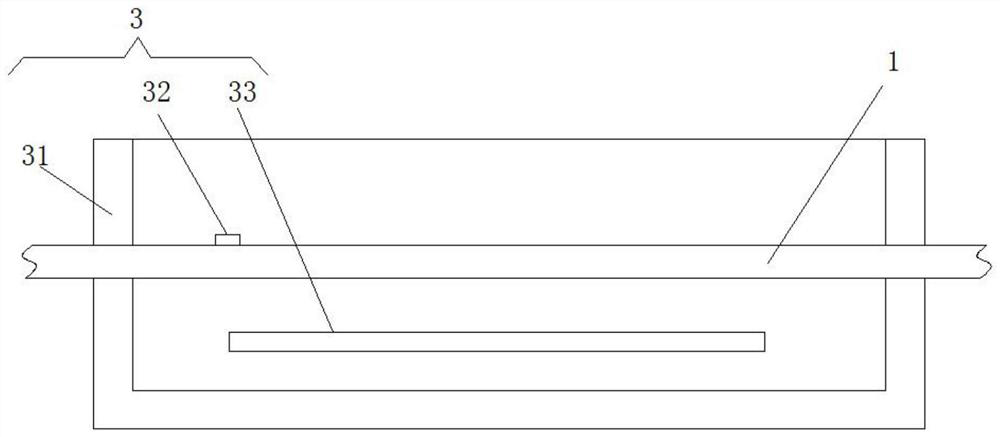

[0022] Such as Figure 1~3 As shown, an energy-saving laminator heating and cooling buffer method comprises the following steps:

[0023] A preheating zone and a cooling zone are respectively set at the feed end and the discharge end of the laminator, and a heat conduction medium circulation is set between the preheating zone and the cooling zone, so that the heat conduction medium circulates between the preheating zone and the cooling zone. The heat transfer medium absorbs heat from the high-temperature discharge component in the cooling zone (component cooling buffer), the temperature of the circulating heat transfer medium rises, and the temperature of the component drops; the heat transfer medium reaches the preheating zone, and the high-temperature circulating heat transfer medium heats the input normal temperature component (component temperature rise buffer ), the temperature of the circulating heat transfer medium drops, and the temperature of the components rises.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com