Ultrafast Laser Fabrication Method and System

A manufacturing system, laser technology, applied in the direction of manufacturing tools, additive manufacturing, active addressing optical modulators, etc., can solve the problems of damaged resolution, processing rate limitation, manufacturing periodic structure limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

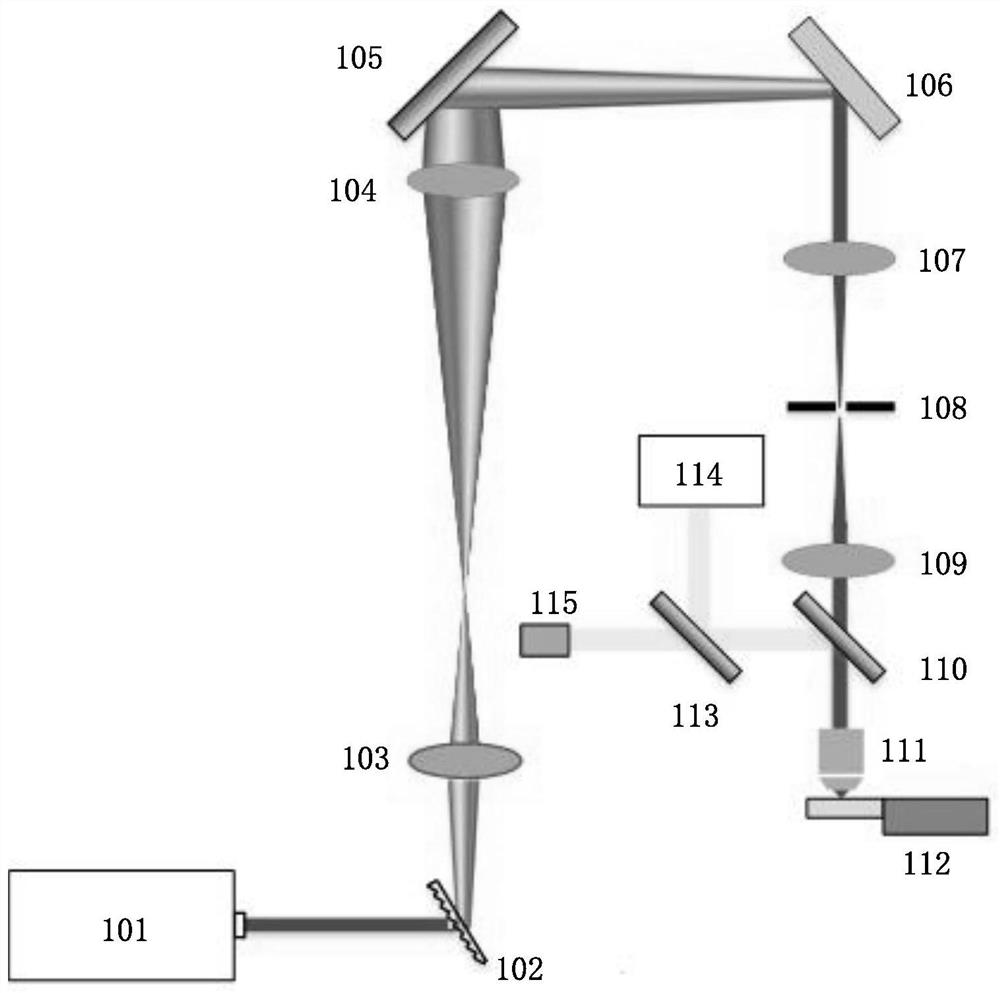

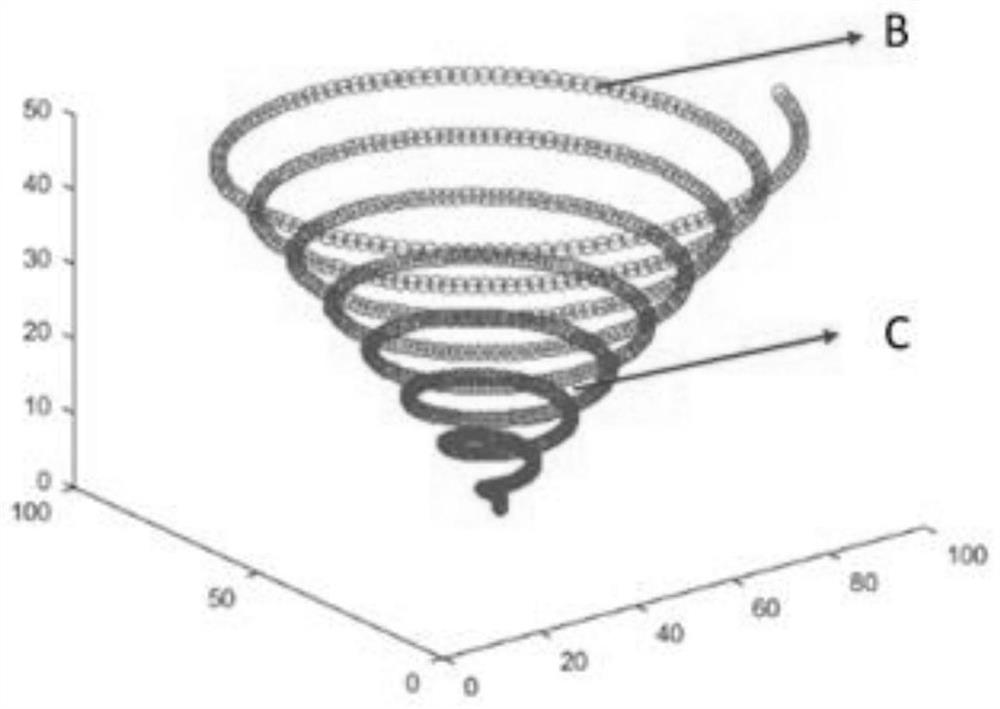

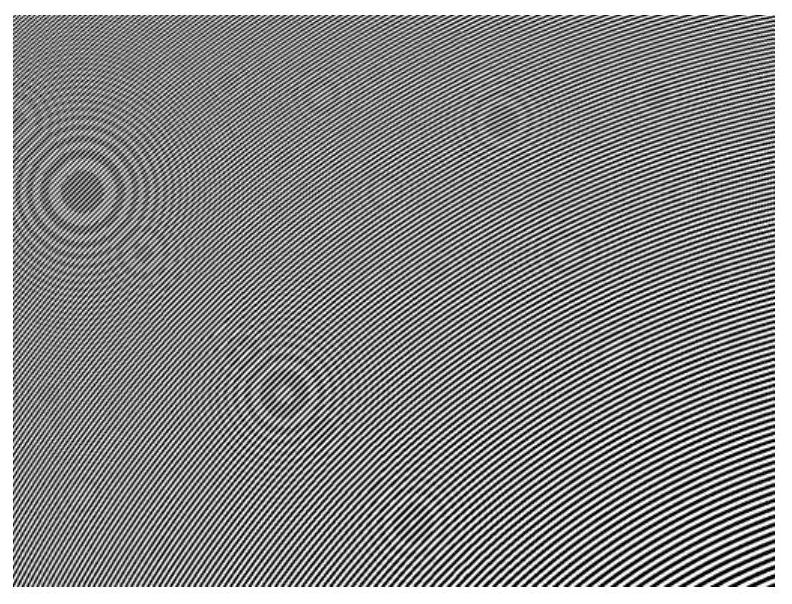

[0025] To achieve high-precision and high-throughput two-photon polymerization, a binary holography-based multifocal DMD random access scanner is proposed. Specifically, the DMD is used as a programmable binary mask encoded with a hologram to modulate the incoming femtosecond laser wavefront. 3D scanning can be achieved by using holographic patterns of spherical wavefronts with tuned tilted phases. To improve scanning resolution, holograms for wavefront correction can be designed and synthesized into scanning holograms to enable simultaneous arbitrary beam shaping and 3D laser scanning with a single DMD. Combining individual focal points by superimposition enables multi-focal random access scanning. Therefore, multi-focus scanning trajectories can be planned arbitrarily to fabricate structures with optimal mechanical properties. Parametric models and computer algorithms were also developed to deterministically relate system performance to DMD parameters. Fabrication experim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com