Waste heat recovery device for chemical reaction furnace

A waste heat recovery device and a technology for chemical reaction, applied in chemical instruments and methods, furnaces, waste heat treatment, etc., can solve the problems of labor-consuming, inconvenient cleaning, low cleaning efficiency, etc., to improve efficiency, prevent residues, and have good condensation effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

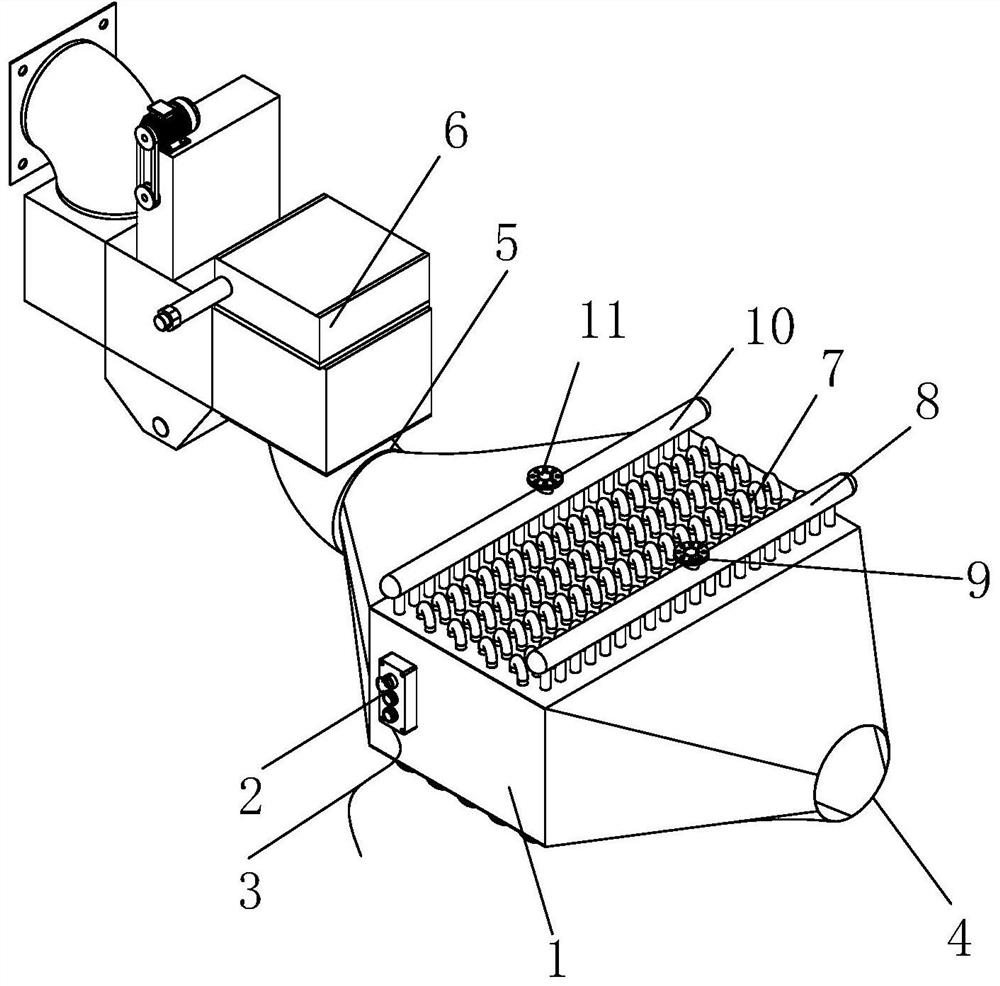

[0031] see figure 1 , the present invention provides a waste heat recovery device for a chemical reaction furnace through improvement, including a heat exchange chamber 1, a controller 2 is fixed on the upper left end of the front surface of the heat exchange chamber 1, and a power cord 3 is arranged at the bottom of the controller 2. There is an air outlet 4 on the right side of the heat exchange chamber 1, the middle part on the left side of the heat exchange chamber 1 is an inlet 5, and a heat exchange tube 7 is embedded in the middle part of the heat exchange chamber 1, and the top right end of the heat exchange tube 7 is connected to the water outlet pipe 8. Water outlet 9 is fixed in the middle part of the top of water outlet pipe 8, water inlet pipe 10 is arranged at the left end of heat exchange pipe 7 top, water inlet 11 is installed in the middle part of the top of water inlet pipe 10, and the left side of inlet 5 is connected with pretreatment device 6.

[0032] see...

Embodiment 2

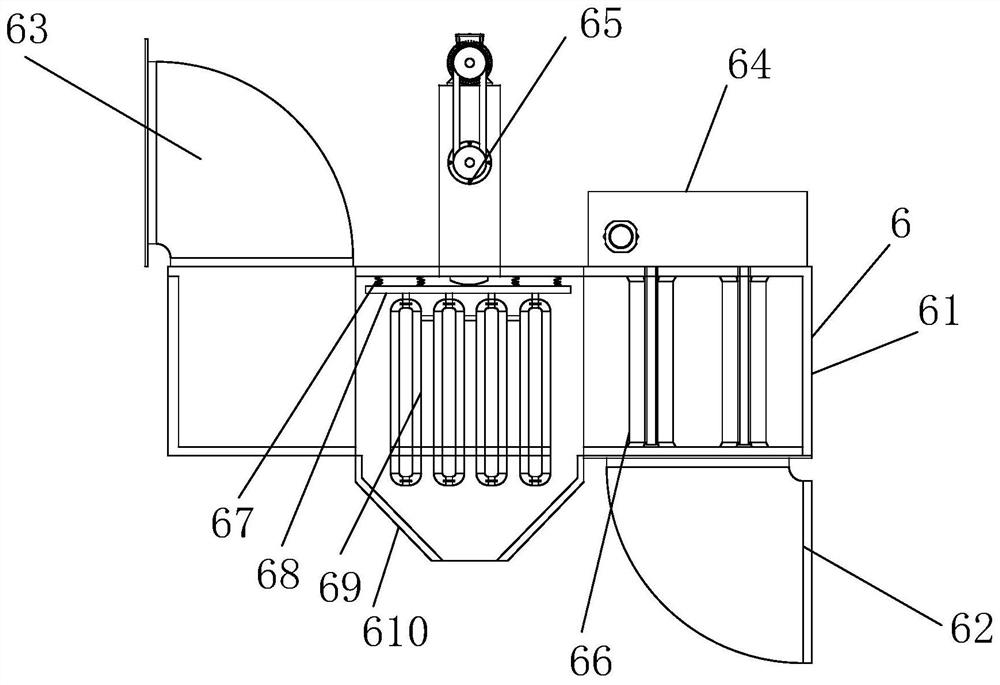

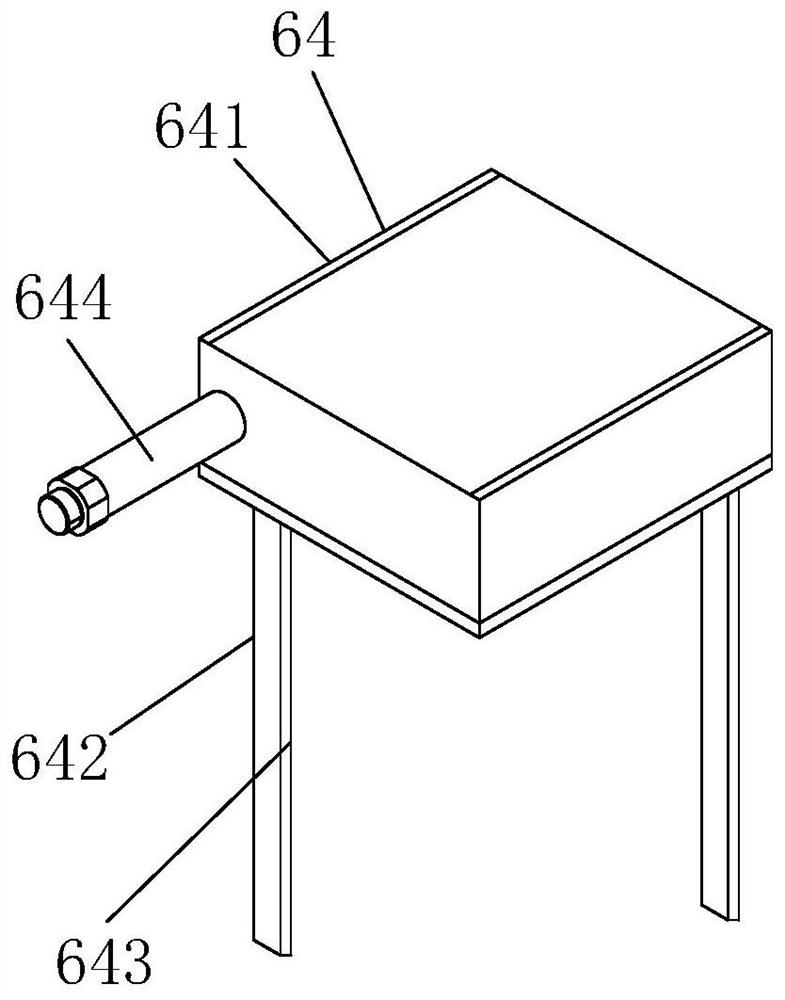

[0037] The present invention provides a waste heat recovery device for a chemical reaction furnace through improvement. A sealing cover is provided on the back of the casing 61, and the sealing cover is bolted to the casing 61, which is convenient for the user to inspect and maintain the inside of the casing 61; The inner wall of 61 is smooth, which reduces the adhesion of impurities and facilitates cleaning; the left side of the inlet 5 and the outlet pipe 62 are fixed by six sets of bolts, and a rubber layer is attached to the connection position of the two to prevent leakage; the guide seat 6510 There is a sliding groove in the middle, and the sliding groove is movably embedded by the pressing piece 658, which effectively guides the movement of the pressing piece 658 and has good stability.

[0038] The present invention provides a waste heat recovery device for a chemical reaction furnace through improvement, and its working principle is as follows;

[0039] First, when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com